Granite is a relatively hard igneous rock (Mohs hardness 6-7) with a compressive strength of 100-300MPa. It has always been regarded as a "hard bone" in the field of crushing and processing. According to statistics, in the sand and gravel aggregate production line, the wear cost of granite crushing equipment is 40%-60% higher than that of ordinary limestone. How to choose efficient and economical crushing equipment according to the characteristics of granite? This article will analyze the 7 key selection indicators in detail for you and provide a comparative analysis of mainstream equipment.

1. Physical properties and crushing difficulties of granite

1.1 Analysis of mineralogical properties

• Quartz content: 20%-40% (main source of wear)

• Feldspar and mica: affect the shape of crushed particles

• Crystal structure: equigranular structure leads to high crushing energy consumption

1.2 Difficulties in crushing process

• High energy consumption: 30%-50% higher electricity consumption per ton than limestone

• High wear: 40%-70% shorter life of hammer/liner

• Finished product requirements: needle-like content must be controlled within 10% (GB/T 14685 standard)

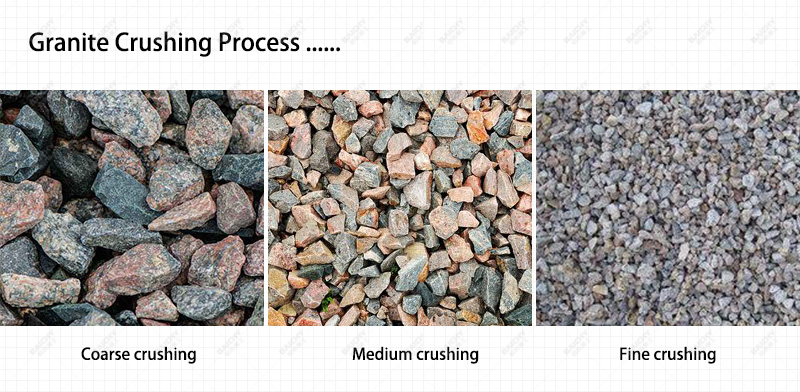

2. Comparison of performance of mainstream crushing equipment

| Equipment type | Feed size (mm) | Discharge size (mm) | Applicable stage | Power consumption per ton (kWh/t) | Life of wear-resistant parts (10,000 tons) |

| Jaw crusher | ≤1500 | 50-200 | Coarse crushing | 0.8-1.2 | 8-12 |

| Cone crusher | ≤300 | 10-50 | Medium and fine crushing | 1.2-1.8 | 15-25 |

| Impact crusher | ≤60 | ≤5 | Sand making | 2.0-3.5 | 5-8 |

Note: The data is based on granite processing conditions, and the actual value is affected by ore composition and equipment model

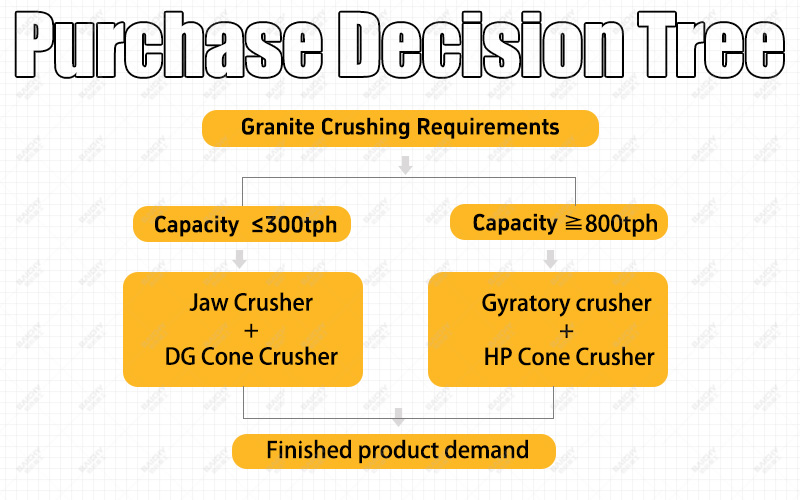

The following is a professional recommendation for granite crushing equipment for different production needs, including a comparison of mainstream brands, models and technical parameters:

• Jaw crusher - Recommended coarse crushing equipment (feed size ≤ 1500mm)

Feed port: 1500×1100mm

Processing capacity: 480-1160t/h

Features: Modular design, hydraulic adjustment of discharge port

Applicable scenarios: Primary crushing of granite mines, suitable for processing high-hardness, large-block raw materials.

• Gyratory crusher - Recommended coarse crushing equipment (preferred for output ≥ 1000 tons per hour)

Processing capacity: 4500-13000t/h

Spindle stroke: 94mm

Features: Intelligent control system automatically adjusts the load

• Multi-cylinder hydraulic cone crusher - Recommended medium and fine crushing equipment (feed ≤ 300mm)

Maximum feed: 230mm

Discharge range: 10-51mm (adjustable)

Features: Laminated crushing, finished cubes account for ≥ 85%

The hydraulic system overload protection response time is <0.5 seconds, and the liner adopts high manganese steel + tungsten carbide composite coating (life increased by 40%).

• Single-cylinder cone crusher (preferred for small and medium production capacity)

Processing capacity: 120-580t/h

Hydraulic motor adjustment accuracy: ±1mm

Power consumption: 15% lower than traditional models

3. Typical production line configuration plan

3.1 200 tons per hour plan (investment of about 8 million)

Raw material warehouse→vibrating feeder→PE1200×1500 jaw crusher (coarse crushing)→intermediate material pile→HST315 cone crusher (medium crushing)→3YK3070 vibrating screen→VSI1140 sand making machine (fine crushing)→finished product warehouse

3.2 500 tons per hour plan (investment of about 15 million)

Heavy plate feeder→C6X160 jaw crusher→HPT500 multi-cylinder hydraulic cone crusher→VSI6X1263 sand making machine→three-stage air screen→stone powder recovery system

4. 3 key points of equipment maintenance

• Temperature monitoring: bearing temperature ≤75℃ (infrared monitoring)

• Vibration control: amplitude ≤4mm/s (online monitoring system)

• Wear warning: it is recommended to install intelligent wear detection sensor

Professional advice: before selecting equipment, be sure to conduct a Bond Work Index test. We provide free technical consultation and sample testing services. Please contact our engineering team for customized solutions.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)