As a representative of high-hardness rocks, granite is widely used in building aggregates, highway construction and large-scale infrastructure projects. However, its high compressive strength (usually 200-300MPa) and strong abrasiveness pose severe challenges to crushing equipment and processes. How to design a set of efficient granite crushing solutions with an output of 200 t/h? This article will deeply analyze the equipment selection, process flow and cost optimization strategy to help you build a cost-effective production line.

1. The core challenges of 200t/h granite crushing

• High hardness leads to fast equipment wear: Granite has a Mohs hardness of 6-7, and the life of traditional hammer crushers and impact crushers is short.

• Strict requirements for finished product particle shape: The aggregate market has high requirements for needle-like content (generally ≤15%), and the crushing process needs to be optimized.

• Environmental protection and energy consumption issues: Large-scale production lines need to take into account low noise and low dust emissions, while reducing the cost of electricity per ton.

Solution: Adopt "multi-stage crushing + laminated crushing" process, combined with intelligent control system, to achieve efficient and energy-saving production.

2. 200t/h granite crushing production line design

2.1 Equipment selection: jaw crusher + cone crusher + shaping sand making machine

| Equipment type | Recommended model | Function | Advantages |

| Coarse crushing | PE1200×1500 jaw crusher | Handling large granite (≤800mm feed) | High crushing ratio, wear resistance |

| Medium crushing | HST315 single-cylinder hydraulic cone crusher | Secondary crushing to 50-80mm | Laminated crushing, excellent particle shape |

| Fine crushing/shaping | VSI6X1145 impact sand making machine | Producing 0-5mm machine-made sand | The finished product has rounded particles and controllable powder content |

| Auxiliary equipment | 3YK3070 vibrating screen, belt conveyor, dust removal system | Screening and grading, environmentally friendly dust reduction | Intelligent control |

Key points:

• Cone crusherreplaces impact crusher: granite crushing prefers hydraulic cone crusher, and the life of wear-resistant parts is increased by more than 50%.

• "Screen before crushing" process: pre-screening by vibrating screen reduces over-crushing and reduces energy consumption by 10%-15%.

2.2 Process optimization (with flow chart)

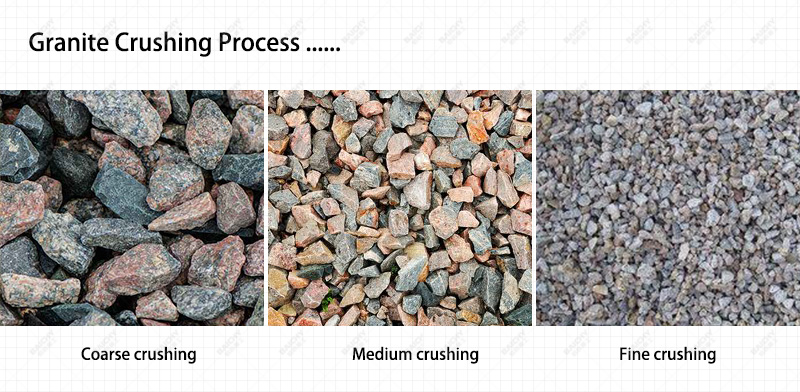

Three-stage closed-circuit crushing solution:

Coarse crushing stage: jaw crusher crushes the raw ore to ≤200mm.

Medium crushing stage: cone crusher further crushes, closed-circuit screening (screened material returns to cone crusher).

Sand making and shaping: impact crusher processes 5-30mm aggregate to produce high-quality machine-made sand.

Unique design:

• "Flexible adjustment" system: By hydraulically adjusting the cone crusher discharge port, 4-6 finished product specifications (such as 0-5mm, 5-10mm, 10-20mm) can be quickly switched.

• Dry dust removal + water mist dust suppression: Combined with pulse dust removal and spray dust suppression, dust emission ≤20mg/m³ (national standard requirement).

3. Cost and benefit analysis

3.1 1. Investment cost estimation (reference)

| Project | Cost (RMB 10,000) |

| Equipment procurement (jaw crusher + cone crusher + sand making machine) | RMB 350-450 |

| Steel structure and conveying system | RMB 80-120 |

| Electrical and intelligent control system | RMB 50-80 |

| Environmental protection facilities (dust removal + noise reduction) | RMB 30-50 |

| Total investment | RMB 5-7 million |

3.2 Operational economy

Power consumption per ton: 1.8-2.2kWh/t (15% lower than traditional solutions).

Wear-resistant parts cost: Cone crusher mortar wall life ≥6 months, ton crushing cost ≤2 yuan.

Payback period: Calculated based on the market price of granite aggregate 60-80 yuan/ton, 1.5-2 years to pay back.

4. Industry cutting-edge trends: intelligent and green crushing

• AI optimization system: real-time monitoring of equipment load through sensors, automatic adjustment of feeding speed, and avoidance of "idling" or "overloading".

• Zero-emission plant: wastewater recycling + photovoltaic power generation to create a carbon-neutral crushing production line.

• Mobile crushing solution: suitable for dispersed mining sites, modular design allows for rapid transfer (recommended 200t/h tire-type mobile station).

5. Conclusion: How to customize your 200t/h granite solution?

Key decision factors:

• Raw material characteristics (soil content, block size distribution)

• Finished product requirements (aggregate ratio, sand ratio requirements)

• Site restrictions (fixed/mobile selection)

Baichy Heavy Industry provides free on-site exploration + solution design to match the best equipment combination based on your actual needs. Consult now to get an exclusive configuration list and quotation!

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)