High-Performance Jaw Crushers

In many fields such as mining and construction waste treatment, crushing is the first critical step in material processing. High-performance jaw crushers, with their robust structure, high crushing capacity, and wide material adaptability, have always held a dominant position in the primary crushing stage. For mobile crushing equipment, a reliable high-performance jaw crusher is the heart of the entire production line, directly determining operational efficiency and profitability.

| Key Words | High-Performance Jaw Crushers |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤1200mm |

| Motor Power | 15-280kw |

| Capacity | 5-1100t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. What is a High-Performance Jaw Crusher?

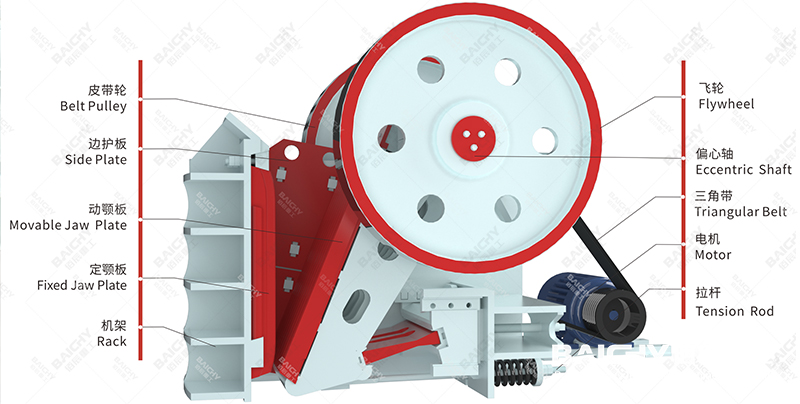

Internal structure diagram of jaw crusher

The working principle of a jaw crusher simulates the movement of an animal's jaws, crushing materials through the periodic squeezing between the moving and stationary jaws. The term high-performance signifies a comprehensive optimization and upgrade of its traditional structure.

1. Revolutionary Structural Design

Modern high-performance jaw crushers typically employ a deeper crushing chamber and a frictionless design, which not only increases feed rate and output but also significantly reduces jaw plate wear. An integrated cast steel frame and large eccentric shaft bearings ensure exceptional stability and an extended service life under heavy loads.

2. Advanced Dynamics

Through computer simulation to optimize the moving jaw's trajectory, the material is not only compressed within the crushing chamber but also slids down, achieving a laminated crushing effect. This significantly improves crushing efficiency and reduces the content of needle-like and flaky products, producing more high-quality cubic aggregate.

II. Why Choose a High-Performance Jaw Crusher? Its Core Advantages Explained

Choosing a truly high-performance jaw crusher can bring immediate benefits to your production projects.

1. Superior Crushing Efficiency and High Output

Optimized chamber shape and higher swing speed significantly increase the material throughput per unit time. This means you can complete more crushing tasks in the same amount of time, directly increasing project profitability.

2. Excellent Reliability and Low Maintenance Costs

Core components are manufactured using high-strength materials and special processes, ensuring excellent durability. The simple modular design makes daily inspection and replacement of wear parts (such as jaw plates) more convenient, minimizing downtime and reducing long-term operating costs.

3. Wide Material Adaptability

From the hardest granite and basalt to construction waste concrete and recycled aggregates, high-performance jaw crushers can handle them all with ease. Their powerful crushing force ensures stable output even when dealing with materials of varying hardness and viscosity.

4. Perfect Integration with Mobile Crushing Stations

As a professional manufacturer of mobile crushing equipment, our high-performance jaw crushers are designed for mobile installations. Their compact structure, integrated feeder, and pre-screening device allow for quick installation on mobile chassis, forming a highly efficient and flexible heavy-duty mobile jaw crushing station, enabling convenient relocation and rapid commissioning.

III. Success Story: Field Application of High-Performance Jaw Crusher

Basalt crushing site at a jaw crusher production line in Mexico

A large granite quarry in Mexico, previously using a traditional jaw crusher, faced problems of low efficiency and poor product particle shape. We configured their mobile crushing production line with a C-series high-performance jaw crusher.

• Results: Hourly output increased by approximately 30%, and the content of needle-like and flaky particles in the product decreased by more than 15%, meeting the demands of the high-end building materials market. Meanwhile, due to the high reliability of the equipment, unexpected downtime of the production line is reduced by more than 50%, creating significant economic value for customers.

IV. Recommended Related Equipment

A high-performance jaw crusher typically needs to work in conjunction with other equipment to form a complete closed-loop cycle. We recommend considering the following:

• Medium-duty cone crusher: Used for medium and fine crushing, producing smaller, high-quality aggregates.

• Heavy-duty circular vibrating screen: Used for precise grading of crushed materials.

• Mobile impact crusher: Can form a flexible secondary crushing combination if material shaping is required.

V. Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of the jaw plates on a high-performance jaw crusher?

A: Jaw plate lifespan depends on the hardness, abrasiveness, and output of the material being crushed. Generally, for crushing medium-hard granite, jaw plate lifespan can reach hundreds to thousands of hours. We offer jaw plates made of different materials (such as manganese steel and alloy steel) to suit different working conditions.

Q2: Is the equipment easy to maintain?

A: Yes. Modern high-performance jaw crushers are designed with ease of maintenance in mind. Features such as hydraulically adjustable discharge ports and centralized lubrication systems make daily maintenance simple and quick. Replacement of wear parts also requires no complicated tools.

Q3: Can you customize to fit our special mobile chassis?

A: Absolutely. As a professional manufacturer, we offer flexible customization services. Our engineering team can tailor the most suitable high-performance jaw crusher installation solution for you based on your specific mobile chassis specifications and capacity requirements.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!