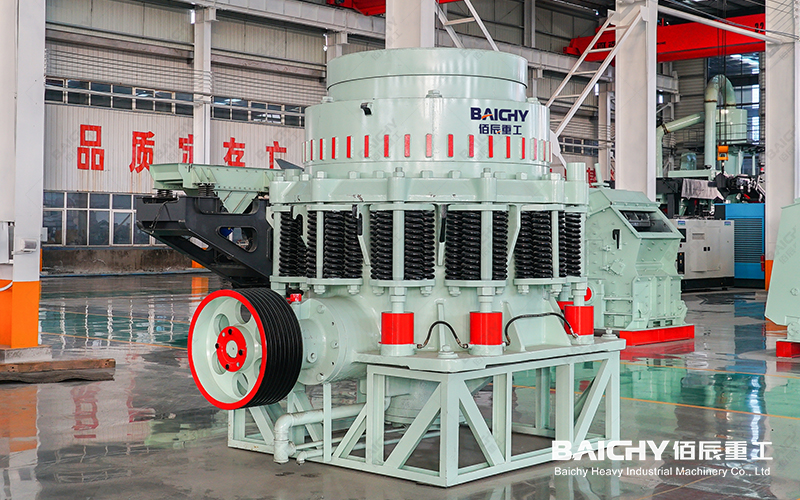

symons cone crusher

Cone crushers are one of the core pieces of equipment in mobile crushing production lines in mines, primarily used for secondary or tertiary crushing of materials with medium to high hardness. Their unique layered crushing principle and high-efficiency hydraulic system give them significant advantages when crushing ores, rocks, and other materials with high hardness. As a manufacturer of mobile crushing equipment for mines, we are committed to providing high-performance, high-stability cone crushers to meet the production needs of mines of different sizes.

Working Principle of Cone Crusher Equipment

Layered Crushing Principle

The cone crusher adopts the layered crushing principle, where materials are subjected to multiple compression, impact, and bending actions between the moving and stationary cones, achieving selective crushing. This principle not only effectively reduces over-crushing but also significantly improves crushing efficiency and product particle shape quality.

Hydraulic System Control

Modern cone crushers are typically equipped with a hydraulic system for adjusting the discharge opening size, overload protection, and chamber clearing operations. The hydraulic system makes equipment operation simpler and safer, while also improving the level of automation and reliability.

Advantages of Cone Crusher Equipment

1. High Efficiency and High Capacity

Cone crushers boast a high crushing ratio and capacity, making them suitable for large-scale, continuous production lines. Their optimized cavity shape and high oscillation frequency ensure a significantly higher throughput per unit time compared to other types of crushers.

2. Excellent Product Particle Shape

Due to the layered crushing effect, cone crushers produce products with predominantly cubic particle shapes and low needle-like and flaky content, making them ideal for high-grade construction, highway construction, and other fields with stringent requirements for aggregate particle shape.

3. Low Operating Costs

Key components of cone crushers, such as the moving cone and fixed cone, are made of highly wear-resistant materials, resulting in a long service life and reduced replacement frequency and maintenance costs. Furthermore, their energy-saving design effectively reduces power consumption during production.

Cone Crusher Plant

Practical Application Cases

Case 1: A Large Granite Mine Project

In this project, one of our multi-cylinder hydraulic cone crushers was used for secondary crushing, with a processing capacity of 450 tons per hour. The product had uniform particle size, with needle-like and flaky particles accounting for less than 10%. The client was very satisfied with the equipment's stability and output quality.

Case 2: Mobile Crushing Production Line

We designed a mobile crushing production line for a client, with core equipment including a jaw crusher and a cone crusher. The cone crusher, in particular, has excellent mobility and rapid commissioning capabilities, making it especially suitable for short-term mining projects.

Recommended Related Equipment

- Jaw Crusher: Used as primary crushing equipment in conjunction with a cone crusher to achieve a perfect connection between coarse and medium crushing processes.

- Vibrating Screen: Used for grading the cone crusher output, improving the overall production line efficiency.

- Mobile Crushing Station: Integrates feeding, crushing, and screening into one unit, suitable for mining operations with frequent relocation.

FAQ

Frequently Asked Question 1: What materials are suitable for cone crushers?

Cone crushers are suitable for materials with medium to high hardness, such as granite, basalt, and iron ore. They are not suitable for crushing sticky materials or materials with high soil content.

Frequently Asked Question 2: How to choose the cavity type of a cone crusher?

The cavity type selection mainly depends on the feed particle size, capacity requirements, and product particle size requirements. Standard cavity types are suitable for medium crushing, while medium and short-head cavity types are suitable for fine crushing. Specific selection needs to be determined based on the production process.

Frequently Asked Question 3: What are the key maintenance points for cone crushers?

Regularly checking the wear of wear parts, keeping the hydraulic system clean and maintaining the oil level, and paying attention to abnormal vibrations and noise during equipment operation are crucial for ensuring the long-term efficient operation of the cone crusher.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!