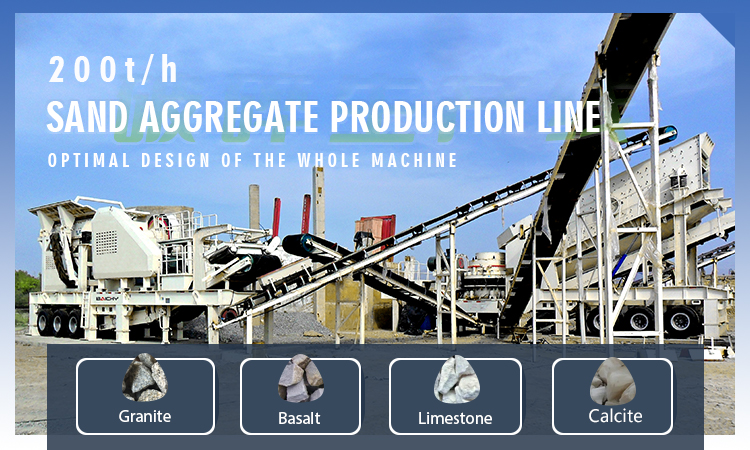

With the continued strong demand for sand and gravel aggregates, building an efficient, stable, and highly profitable production line is a key priority for every investor. For medium-sized production lines with a 200-ton-per-hour (TPH) output, the selection of the primary jaw crusher—the "heart" of the production line—is crucial. The PE-750x1060 jaw crusher, with its exceptional performance, has become a star performer in this field.

This article will provide an in-depth understanding of this equipment and outline a complete configuration plan for a 200-ton-per-hour (TPH) aggregate production line.

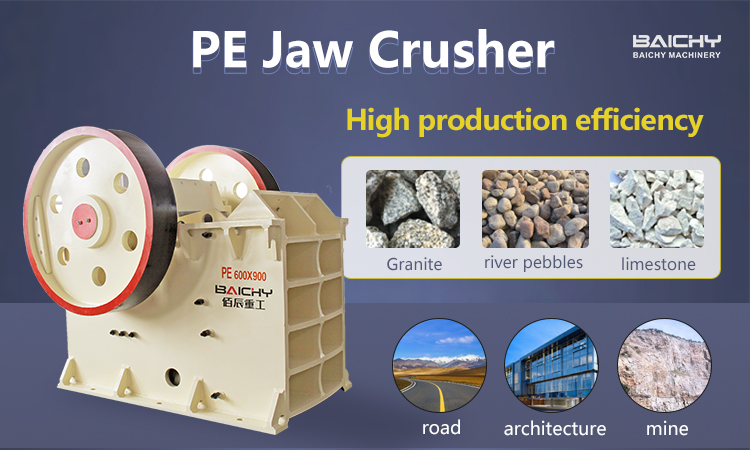

1. Why is the PE-750x1060 the "ideal core" of a 200-ton-per-hour (TPH) production line?

The PE-750x1060 is more than just a model number; it represents a market-proven, premium configuration.

1. Perfectly Matched Processing Capacity: Its feed opening measures 750x1060mm, easily handling large ores under 500mm (such as granite, basalt, and river pebbles). Its theoretical processing capacity reaches 200-280 tons per hour, perfectly aligned with the production target of "200 tons per hour" with no performance loss and no capacity bottlenecks.

2. Sturdy Structure and Stable Operation: Utilizing a high-quality cast steel frame and high-manganese steel movable jaws, the equipment is durable and highly impact-resistant, ensuring continuous and stable operation when crushing hard materials with a low failure rate, laying the foundation for high year-round availability.

3. High Crushing Efficiency and Uniform Output Size: The deep-cavity crushing design not only increases output but also optimizes crushing results. By adjusting the jaw gap, the output size can be easily controlled between 100-250mm, providing ideal feed material for subsequent secondary crushing and reducing pressure on the secondary crushing equipment. 4. Economical Operating Costs: The simple structure allows for easy maintenance, while the replacement cycle for wearing parts (such as jaw plates) is long, significantly reducing long-term maintenance costs and downtime.

II. Complete Core Configuration for a 200-ton-per-hour Aggregate Production Line

An efficient production line is like a team, requiring all equipment to work together. The following is a typical configuration for the PE-750x1060 jaw crusher:

• Feeding System: The ZSW-490x110 vibrating feeder provides uniform and continuous feeding to the jaw crusher, preventing it from clogging or running dry.

• Primary Crushing System: The PE-750x1060 jaw crusher (core equipment) is responsible for primary crushing of bulky raw materials.

• Secondary Crushing System: Either a cone crusher (such as the PYB1750) or an impact crusher (such as the PF-1315) is available. Cone crushers are suitable for high-hardness materials and offer excellent wear resistance; impact crushers are suitable for medium-hardness materials and produce a superior final particle size. • Screening System: 2-3 YZS-2460 vibrating screens classify the crushed material. Qualified products are sent to the finished product pile, while oversized particles are returned to the secondary crushing equipment for further processing (closed-loop operation).

• Conveying and Dust Removal System: Belt conveyors connect all stages, and pulse bag dust collectors ensure environmentally friendly production.

Simplified Process Flow:

Raw Materials → Vibrating Feeder → PE-750x1060 Jaw Crusher (Coarse Crushing) → Cone Crusher/Impact Crusher (Secondary Crushing) → Vibrating Screen (Screening) → Finished Aggregates (Various Specifications).

III. What Will You Gain from Investing in This Production Line?

1. Substantial Returns: Based on a 10-hour operation per day and 25 days per month, monthly production can reach 50,000 tons, sufficient to meet the supply needs of most regional markets and providing a high return on investment. 2. Product Flexibility: By adjusting the screen size, we can produce high-quality aggregates in a variety of sizes, including 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm, meeting the perse needs of customers in ready-mix concrete plants, highways, and construction projects.

3. Long-Term Stability: A production line built around classic models like the PE-750x1060 offers mature technology and an ample supply of spare parts, ensuring stable and sustainable production for the next 5-10 years.

Choosing a production line means investing in your future. The PE-750x1060 jaw crusher, the backbone of a 200-ton-per-hour aggregate production line, has earned widespread market recognition. However, each ore source, site planning, and finished product requirements are unique.

Please feel free to contact us! Our technical engineers will provide a free, one-on-one production line design and detailed equipment quote based on your specific requirements, helping you make the most informed investment decision.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)