Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

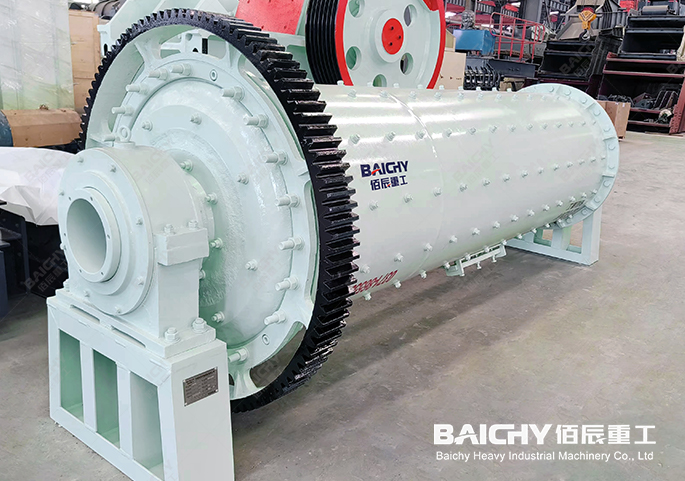

The 900x3000 ball mill, with its moderate dimensions, excellent energy efficiency, and wide applicability, strikes an excellent balance between processing capacity, equipment investment, and operating costs. Consequently, it has become one of the most popular models for small and medium-sized mineral processing plants, chemical plants, and building materials factories.

This ball mill strikes a perfect balance between investment cost and production efficiency. Its key advantages are:

1. Wide Application Range: It can be used for grinding a variety of metal ores, including gold, copper, iron, lead, and zinc, as well as non-metallic ores.

2. Low Investment Threshold: Compared to larger equipment, its purchase cost and ongoing maintenance are more manageable, resulting in a shorter payback period.

3. Compact Structure and Easy Operation: It occupies a small footprint, requires relatively little installation infrastructure, and is easily automated, reducing labor costs.

Ball mill cylinder

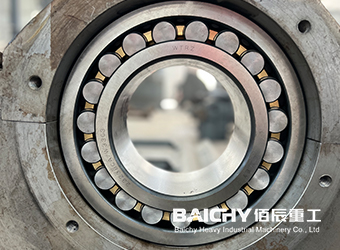

Ball mill bearing

Ball mill liner

Grinding media steel balls

| Model | Ф900x3000 |

|---|---|

| Cylinder Rotating Speed (r/min) | 36 |

| Ball weight(t) | 2.7 |

| Feeding Size(mm) | ≤20 |

| Discharging Size(mm) | 0.075-0.89 |

| Capacity(t/h) | 1.1-3.5 |

| Power(kw) | 22 |

A: The 900x3000 ball mill is typically equipped with a 37-45kW motor. As a mid-sized machine, its design prioritizes energy efficiency, resulting in reasonable energy consumption at full capacity, making it ideal for cost-conscious small and medium-sized businesses.

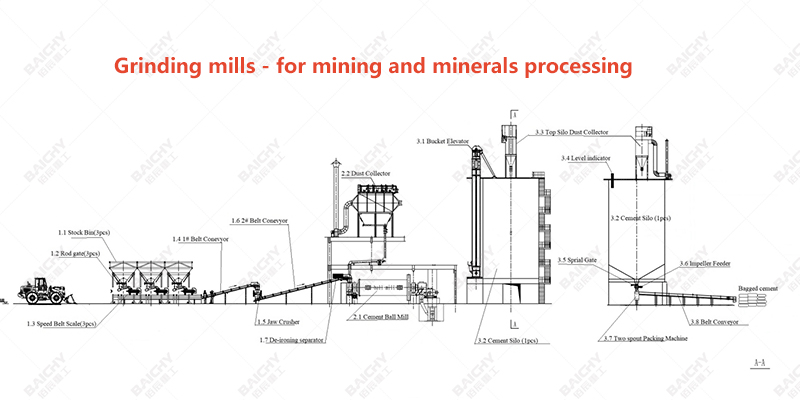

A: The machine must be installed on a solid concrete foundation. The depth and strength of the foundation must be professionally calculated to withstand the dynamic loads during operation. While the foundation requirements are lower than those for larger ball mills, it still needs to be level and provide ample space for operation and maintenance.

A: The grinding media ratio directly impacts grinding efficiency. We recommend a multi-stage ball mixing solution, with large balls (e.g., φ80mm, φ60mm) responsible for impact crushing, and small balls (e.g., φ40mm, φ20mm) for grinding. For an initial mixing ratio, refer to the equipment manual, or our technicians can provide professional advice based on your material characteristics.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.