Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

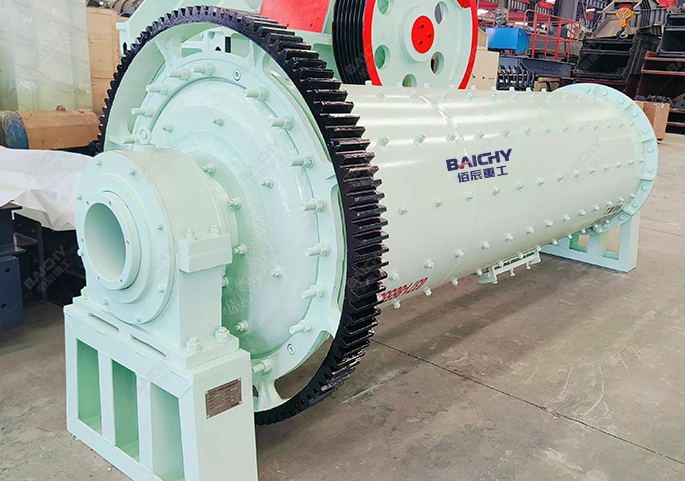

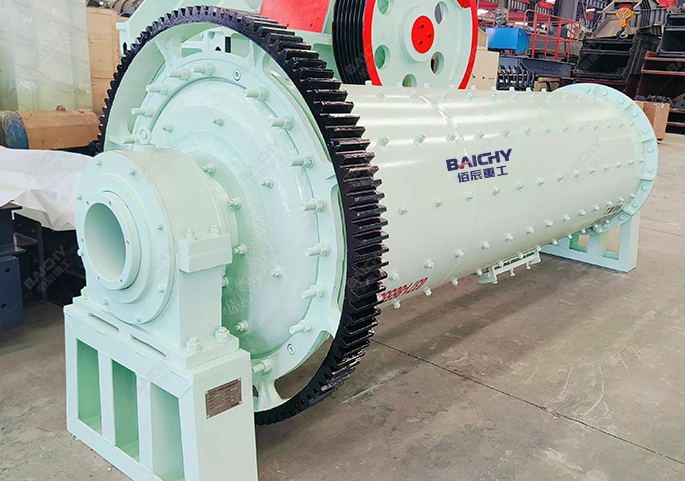

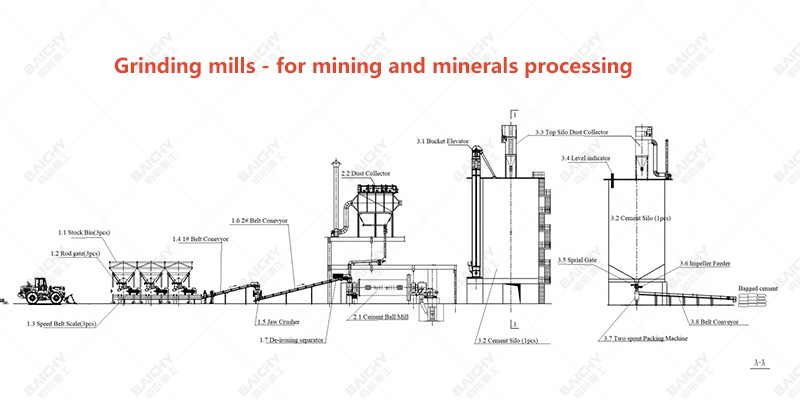

Ball mills are essential core grinding equipment in industries such as ore processing, building materials, and chemicals. Choosing the right model is crucial for mineral processing plants or experimental bases with medium-volume processing requirements. The 900x1800 ball mill stands out among many models for its moderate output, low energy consumption, and flexible configuration, earning it the title of "golden choice" for small- and medium-scale grinding operations.

1. Low Investment Cost: Compared to larger ball mills, its purchase and ongoing maintenance costs are more economical, resulting in a shorter payback period.

2. Moderate Energy Consumption and Economical Operation: The matching motor has reasonable power, effectively reducing long-term power consumption.

3. Compact Structure and Small Footprint: Ideal for small- and medium-sized mineral processing plants or mobile crushing and grinding lines with limited space.

4. Easy Operation and Maintenance: Its sophisticated structural design requires minimal technical expertise for daily operation and maintenance, effectively reducing labor costs. 5. Wide Application: It can be used for grinding a variety of metal ores, including gold, copper, iron, lead, and zinc, as well as non-metallic ores such as quartz, feldspar, and fluorite.

With its balanced performance and excellent cost-effectiveness, the 900x1800 ball mill is an ideal starting point for achieving efficient and energy-saving production for small and medium-sized mineral processing projects. Fully understanding its performance and matching it with your production needs will maximize the value of your investment.

Ball mill cylinder

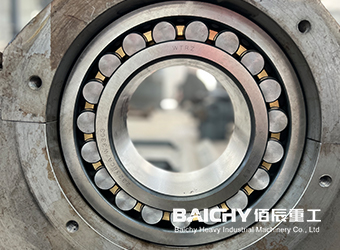

Ball mill bearings

Ball mill lining

Grinding media steel balls

| Model | Ф900×1800 |

|---|---|

| Cylinder Rotating Speed (r/min) | 36-38 |

| Ball weight(t) | 1.5 |

| Feeding Size(mm) | ≤20 |

| Discharging Size(mm) | 0.075-0.89 |

| Capacity(t/h) | 0.65-2 |

| Power(kw) | 18.5 |

A1: This is a common question, but it's not universally applicable. Its processing capacity (output) typically fluctuates between 0.5 and 1.8 tons/hour. The specific value depends on the hardness of the ore you're processing (for example, the output of granite and limestone will vary significantly) and the required fineness of the output. We recommend providing a sample of your material to the equipment manufacturer for a grindability test to obtain the most accurate capacity data.

A2: The price of a 900x1800 ball mill is influenced by many factors, including the equipment material (e.g., manganese steel liner), motor brand, manufacturer, and whether taxes and shipping are included. Market prices range widely, typically from tens of thousands to hundreds of thousands of RMB. We recommend contacting multiple reliable manufacturers directly and providing detailed configuration requirements for an accurate quote.

A3: A 900x1800 ball mill can generally be designed for both wet and dry grinding. Wet grinding generally offers higher throughput, less dust, and is more widely used. Please specify your process requirements when ordering, and the manufacturer will configure the appropriate discharge and transmission components based on your selection.

A4: Ball mills are heavy equipment and require high installation precision, including foundation pouring, main unit hoisting, and transmission component alignment. It is strongly recommended that the equipment supplier provide installation guidance or send technicians to perform on-site installation and commissioning directly to ensure the normal operation of the equipment and avoid early damage caused by improper installation.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.