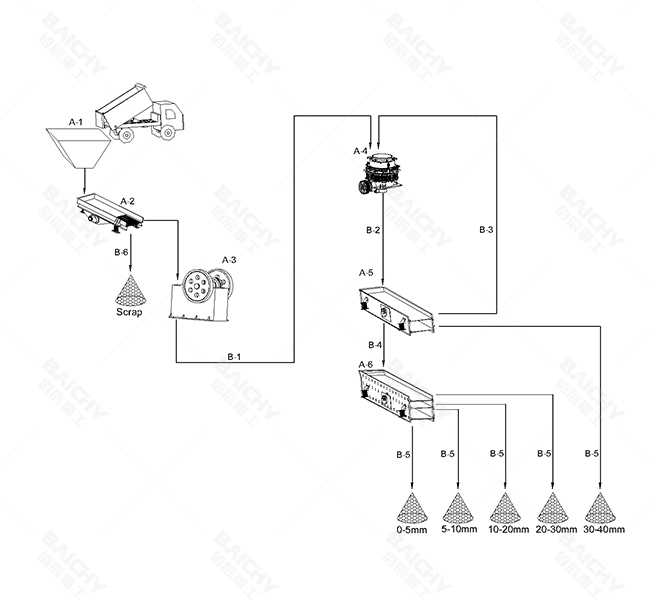

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW960X3800 | 1 |

| A-3 | Jaw Crusher | PE600X900 | 1 |

| A-4 | Cone Crusher | CS110 | 1 |

| A-5 | Vibrating Screen | 2YK1860 | 1 |

| A-6 | Vibrating Screen | 3YK1848 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B800 | 18m | 1 |

| B-2 | B800 | 21m | 1 |

| B-3 | B650 | 23m | 1 |

| B-4 | B650 | 23m | 1 |

| B-5 | B500 | 15m | 5 |

| B-5 | B500 | 10m | 1 |

80-120 t/h Hard Rock Crushing Solution: Rapid Return on Investment in 6-9 Months, Injecting Powerful Momentum into Your Medium-Sized Stone Quarry

We have specialized in medium-sized aggregate production linesfor 20 years, successfully delivering over 2000 projects. We understand that a high-yield, stable, and profitable production line is not simply a collection of equipment, but a systematic solution based on profound experience and exquisite craftsmanship.

✔ Precise Capacity Matching: Stable output of 80-120 t/h, perfectly balancing investment and capacity.

✔ Excellent Finished Product Quality: Laminated crushing technology ensures flake and elongated particle content is below 10%, resulting in higher aggregate prices.

✔ Leading Energy Consumption Control: Intelligent energy-saving system, with power consumption as low as 1.8 kWh per ton, significantly reducing operating costs.

✔ Worry-Free Environmental Compliance: Full-process dust and noise control, supporting green, compliant, and long-term business development.

✔ Proven Rapid Return on Investment: Scientific configuration and efficient operation help you achieve a rapid return on investment in 6-9 months.

Based on the above capabilities, we have helped many business owners like you systematically solve the following operational challenges:

✘ Is your equipment configuration unreasonable, resulting in production output consistently failing to meet design expectations?

✘ Are electricity costs excessively high, constantly eroding already low profits?

✘ Is the finished product particle shape poor, lacking competitiveness in the market and failing to command a good price?

✘ Are environmental regulations becoming increasingly stringent, with dust and noise complaints hindering production?

✘ Are equipment failures like "gray rhinos," potentially leading to complete production shutdowns at any time?

Rest assured, the problems you face are precisely the issues we have continuously tackled and standardized solutions for in our 2000+ successful cases. We provide a proven integrated delivery of "optimal equipment selection + customized process + lifetime service," ensuring that you operate efficiently and economically from the very first day of production.

Suitable for: Startup stone crushing plants, limited budget, medium raw material hardness

• Primary Crushing: PE-600×900 Jaw Crusher (feed size ≤500mm)

• Secondary Crushing: PF-1214 Impact Crusher

• Screening: 3YK-2160 Vibrating Screen

Southeast Asia Case Study: Granite crushing, actual output 85 tons/hour, power consumption 1.9 kWh/ton

Suitable for: Growing enterprises, requiring high quality and stability of finished products

• Primary Crushing: PE-750×1060 Jaw Crusher

• Secondary Crushing: CS110 Cone Crusher (laminated crushing, flaky particles <10%)

• Screening: 2YK-1860 + 3YK-1848 Double-layer Vibrating Screen

• Excellent finished product particle shape, increasing selling price by 15-20%

• Hydraulic adjustment of cone crusher, saving 15-20% energy

• Dust emission <20mg/m³, noise <75dB

Suitable for: Enterprises with high requirements for capacity, environmental protection, and intelligence

• Primary Crushing: PE-800×1060 Jaw Crusher

• Secondary Crushing: Multi-cylinder hydraulic cone crusher + VSI sand making machine

• Screening: 3YK-3070 Multi-layer Vibrating Screen + Air Screen

• Manufactured sand ratio adjustable up to 50%

• Energy consumption per ton further reduced by 8-10%

Choosing which solution depends not only on your budget, but also on your corporate vision, market strategy, and business philosophy. We recommend that you communicate with us in detail so that we can recommend the most suitable, rather than the most expensive, configuration plan based on your specific needs.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!