Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

As a large, efficient grinding machine, the 3600x4500 ball mill has become the preferred choice of many mining companies for its superior design and stable performance. This article will provide an in-depth analysis of the 3600x4500 ball mill's structural features, operating principle, application scenarios, and maintenance tips, helping you fully understand this important equipment.

The model number of the 3600x4500 ball mill represents its cylinder dimensions: 3600 mm in diameter and 4500 mm in length.

1. Sturdy Cylinder Structure: The cylinder is welded from high-strength steel plates and lined with wear-resistant materials (such as high-manganese steel or rubber lining), effectively extending the equipment's service life.

2. Efficient Drive System: A large reducer is used in conjunction with the motor to ensure smooth startup and continuous operation, with low energy consumption and low noise.

3. Flexible Feed and Discharge Devices: A rational feed and discharge structure is designed based on material characteristics, supporting dry or wet grinding to meet diverse process requirements.

• Metal Mining: Used for grinding metal ores such as gold, silver, copper, and iron, providing material of suitable particle size for subsequent flotation or leaching processes.

• Non-metallic Mineral Processing: Used for fine grinding of non-metallic ores such as phosphate rock, quartz, and feldspar.

• Building Materials Industry: Used for grinding cement raw materials and clinker to improve cement quality.

• Chemical and Power Industries: Also plays a vital role in coal pulverization and metallurgical auxiliary material processing.

The 3600x4500 ball mill, with its large size, high efficiency, and reliability, has become a core piece of equipment in modern mineral processing production lines. Through scientific selection, proper operation, and regular maintenance, companies can maximize its performance advantages and improve overall economic benefits.

Ball mill cylinder

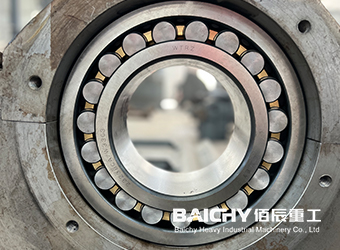

Ball mill bearing

Ball mill liner

Grinding media steel balls

| Model | Ф3600×4500 |

|---|---|

| Cylinder Rotating Speed (r/min) | 17 |

| Ball weight(t) | 90 |

| Feeding Size(mm) | ≤25 |

| Discharging Size(mm) | 0.074-0.4 |

| Capacity(t/h) | 115-170t/h |

| Power(kw) | 850 |

A: These numbers represent the key dimensions of the barrel, the core component of the ball mill. "3600" refers to the barrel's diameter of 3600 mm (3.6 meters), and "4500" refers to its length of 4500 mm (4.5 meters). These dimensions directly determine the equipment's volume and processing capacity, making it a typical large ball mill.

A: Processing capacity (tons/hour) is not a fixed value; it primarily depends on the hardness, density, feed size, and desired product fineness of the material being ground. Generally speaking, the processing capacity of a 3600x4500 ball mill in conventional ore processing ranges from 115 to 170 tons/hour. We need to perform precise calculations and design solutions based on your specific material and process requirements.

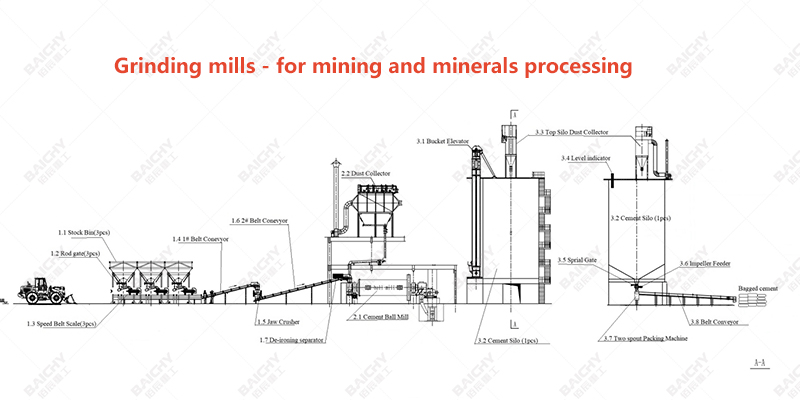

A: A complete grinding system is often referred to as a "grinding plant" or "grinding station." The ball mill is the core, but it also requires the following:

1. Feeding system: vibrating feeder, belt conveyor.

2. Grinding system: ball mill body, supporting motor, reducer, and bearing housing.

3. Discharge system: classifying equipment such as a spiral classifier, hydrocyclone, or vibrating screen.

4. Electrical control system: high and low voltage distribution cabinets, automation control cabinet.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.