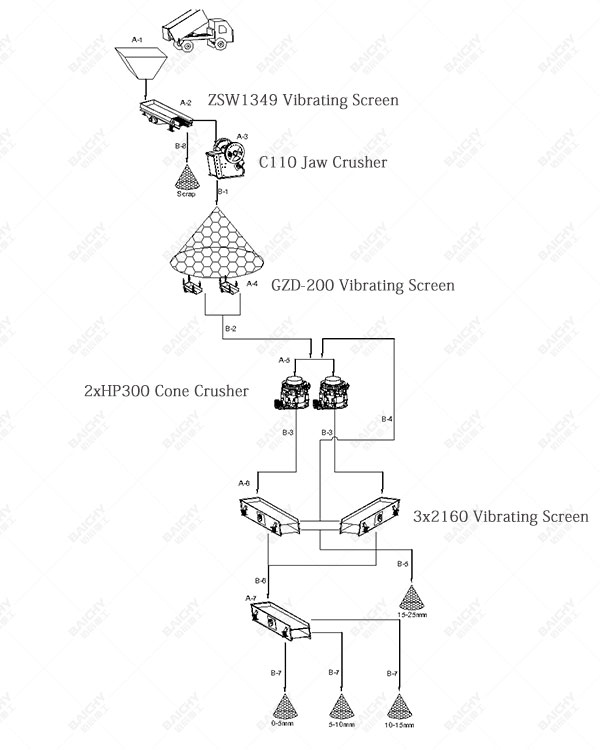

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1300X4900 | 1 |

| A-3 | Jaw Crusher | C100 | 1 |

| A-4 | Vibrating Feeder | GZG-200 | 2 |

| A-5 | Cone Crusher | HP300 | 2 |

| A-6 | Vibrating Screen | 2YK2160 | 2 |

| A-7 | Vibrating Screen | 2YK2160 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1200 | 30m | 1 |

| B-2 | B1200 | (28+8)m | 1 |

| B-3 | B1000 | 23m | 1 |

| B-4 | B1000 | (25+8)m | 1 |

| B-5 | B800 | (25+8)m | 1 |

| B-6 | B1000 | (21+8)m | 1 |

| B-7 | B650 | 25m | 3 |

| B-8 | B650 | 15m | 1 |

Why is it difficult for large-scale production lines to achieve efficient and stable operation? In the sand and gravel aggregate and mining crushing industry, a production capacity requirement of 250-300 tons/hour means you are facing the core challenges of large-scale production lines:

1. Inefficient Hard Rock Crushing: Traditional crushing efficiency for high-hardness materials such as granite and basalt (Mohs hardness 6-7) is less than 75%.

2. Frequent System Capacity Bottlenecks: Improper equipment matching leads to "oversized equipment for small tasks" or "undersized equipment for large tasks," resulting in actual production capacity reaching only 60-80% of the designed capacity.

3. High Comprehensive Operating Costs: Energy consumption accounts for more than 35% of production costs, frequent replacement of wear parts, and high maintenance costs.

• Energy Consumption per Ton: Average 2.8-3.2 kWh/ton

• Equipment Overall Utilization Rate: <75%

• Annual Unplanned Downtime: >300 hours

• Flaky and Elongated Particle Content: >15% (affecting aggregate selling price by 5-10%)

Innovative Solution: Three-Stage Classification + Intelligent Control System

Our solution, specifically designed for crushing high-hardness rocks at 250-300 tons/hour, has successfully helped over 200 large-scale projects worldwide achieve:

✔ 30% Increase in Crushing Efficiency - Through optimized cavity design and crushing ratio distribution

✔ 25% Reduction in Comprehensive Energy Consumption - Driven by intelligent variable frequency control and process optimization

✔ 40% Extension of Equipment Lifespan - Proprietary wear-resistant technology + preventive maintenance system

Granite Aggregate Production Line

Raw Material: High-hardness granite (Mohs hardness 7)

Requirement: 280 tons/hour stable production capacity, 4 finished product specifications

Constraints: 16 hours/day continuous production, annual operation >5500 hours

Process Flow: Vibrating Feeder → C100 Jaw Crusher (Primary Crushing) → HP300 Cone Crusher × 2 (Secondary Crushing) → 2YK2160 Screening System

• Actual Production Capacity: Stable 290-305 tons/hour

• Finished Product Grading: 0-5mm (25%), 5-10mm (30%), 10-20mm (25%), 20-31.5mm (20%)

• Energy Consumption per Ton: 2.1 kWh/ton (30% lower than the industry average)

• Equipment Overall Utilization Rate: 94.3%

We provide complete 250-300 tons/hour rock crushing production line solutions for the aggregate and mining crushing industries. We professionally analyze the crushing challenges of high-hardness materials such as granite and basalt, and provide detailed explanations of the three-stage crushing process configuration, equipment selection guidelines, and intelligent control systems. Our solutions cover the entire process optimization, including jaw crusher primary crushing, cone crusher secondary crushing, and vibrating screen fine screening, helping customers reduce energy consumption by more than 25%, increase production capacity by 30%, and shorten the investment payback period to 12-18 months.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!