Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The 2100x4500 ball mill, a classic medium-sized grinding equipment, is an ideal choice for many small and medium-sized mineral processing plants with its reasonable drum size, excellent processing capacity, and low operating costs.

1. Balanced Processing Capacity: This ball mill strikes a perfect balance between processing capacity and equipment investment, meeting the daily processing needs of hundreds of tons for small and medium-sized mineral processing plants without incurring excessive initial investment pressure.

2. High Grinding Efficiency: The optimized drum aspect ratio ensures sufficient material residence time for thorough grinding. Combined with high-performance liners and grinding media, it effectively grinds materials to the required fineness.

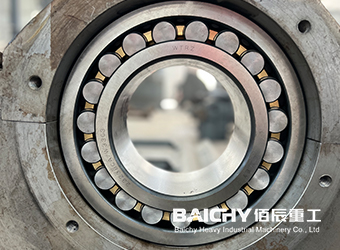

3. Stable and Reliable Operation: The large double-row spherical roller bearing drive replaces traditional Babbitt alloy bearings, resulting in low friction, easy startup, smoother operation, and significantly reduced maintenance. 4. Energy Saving and Environmental Protection: The design prioritizes energy consumption control, with a rational motor power configuration and low energy consumption. It can also be equipped with dust removal and noise reduction devices to meet environmentally friendly production requirements.

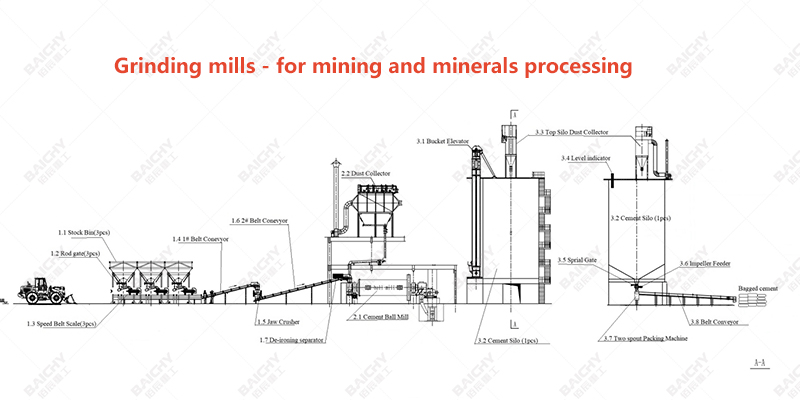

The 2100x4500 ball mill operates on the same principle as other grate-type ball mills. During operation, a motor drives the drum to rotate at a constant speed through a reducer. Centrifugal force and friction lift the material and steel balls within the drum to a certain height, where they then fall in a tossing or cascading motion. The impact and grinding of the steel balls gradually pulverize the material, and powder that meets the required particle size is discharged through the grate plates, completing the grinding process.

Ball mill cylinder

Ball mill bearing

Ball mill liner

Grinding media steel balls

| Model | Ф2100x4500 |

|---|---|

| Cylinder Rotating Speed (r/min) | 23.7 |

| Ball weight(t) | 24 |

| Feeding Size(mm) | ≤25 |

| Discharging Size(mm) | 0.074-0.4 |

| Capacity(t/h) | 8-43 |

| Power(kw) | 245 |

A: Insufficient output is a common problem, typically caused by the following:

• Feeding issues: Insufficient or uneven feed volume results in insufficient feeding of the ball mill; or excessively large feed particles increase grinding difficulty.

• Grinding media issues: Insufficient loading, improper proportioning, or severe wear of the steel balls (or segments) leads to reduced impact and grinding capacity.

• Material property changes: The hardness, moisture content, or grindability of the material being ground has changed, but operating parameters have not been adjusted in a timely manner.

• Cylinder conditions: Excessive wear of the liner, or blockage of the baffle plate or discharge grate, affects material flow and discharge.

A: Abnormal noises, especially metallic clanging sounds, are a danger sign and require immediate inspection.

• First, check the liner bolts: The most common cause is loose bolts securing the liner or end cap, causing the liner to strike the drum during rotation. Stop the machine and tighten all bolts.

• Check the liner: Individual liners may be broken or detached.

• Check the grinding media: Damage to the partition plate may be causing large particles or broken steel balls to enter the next chamber.

• Check the gear transmission: Improper meshing clearance between the large and small gears or poor lubrication can also cause regular, heavy noises.

A: The fineness of the finished product is primarily determined by the grinding media's gradation and ventilation volume. Discharge is too coarse:

• Adjust the steel ball ratio: Increase the proportion of small balls to enhance the grinding effect; or appropriately increase the total steel ball load.

• Check the classifying equipment: If the system is closed-circuit, check the speed and efficiency of the classifier (such as a cyclone separator or concentrator).

Discharge is too fine (may result in reduced yield and over-crushing):

• Adjust the steel ball ratio: Increase the proportion of large balls to enhance impact force and reduce over-grinding.

Increase the feed rate: Increase the material flow rate within the silo to shorten its residence time.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.