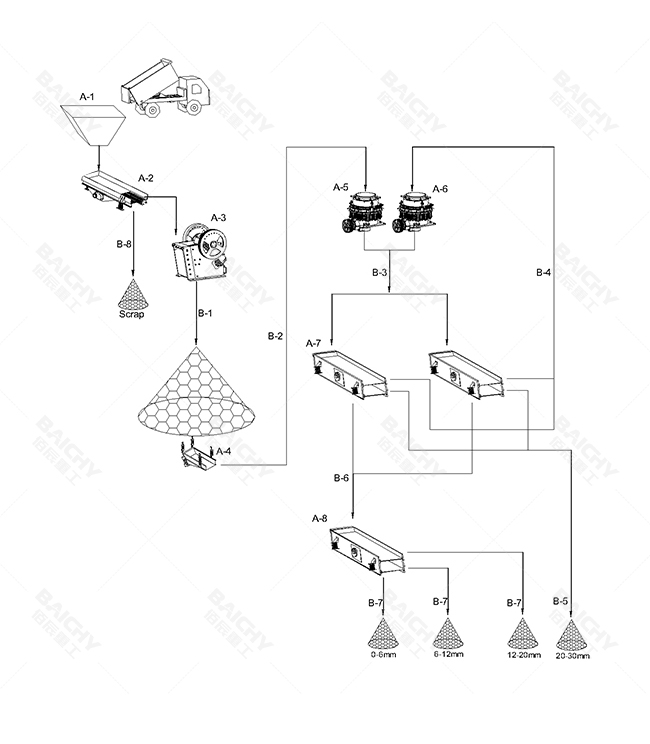

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1100X4200 | 1 |

| A-3 | Jaw Crusher | C100 | 1 |

| A-4 | Vibrating Feeder | GZG-300 | 1 |

| A-5 | Cone Crusher | CS160 | 1 |

| A-6 | Cone Crusher | CS160 | 1 |

| A-7 | Vibrating Screen | 2YK1860 | 2 |

| A-8 | Vibrating Screen | 2YK1860 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1000 | 30m | 1 |

| B-2 | B1000 | (25+8)m | 1 |

| B-3 | B1000 | (26+8)m | 1 |

| B-4 | B800 | (24+8)m | 1 |

| B-5 | B650 | (20+8)m | 1 |

| B-6 | B800 | (21+8)m | 1 |

| B-7 | B650 | 20m | 3 |

| B-8 | B650 | 15m | 1 |

Addressing the challenge of crushing high-strength rocks, we offer a professional, high-yield "jaw crusher + cone crusher" multi-stage crushing solution, ensuring stable production of high-quality construction aggregates that fully comply with the GB/T 14685-2022 national standard. It is a reliable choice for large-scale quarries and infrastructure projects.

• Dual cone crusher parallel design: Achieves continuous and stable output of 200-250 tons/hour, with a peak capacity of 250 tons.

• High-strength structural configuration: Optimized for highly abrasive materials such as granite and basalt, reducing failure rate by 40%.

• Laminated crushing technology: The CS160 cone crusher saves 15-20% energy compared to traditional equipment.

• Optimized particle shape: Finished product contains less than 10% flaky and elongated particles, and less than 8% for high-quality projects.

• Precise grading: Multi-stage screening ensures accurate grading of 0-5mm, 5-10mm, 10-20mm, and other specifications.

• High standard applicability: Fully meets the stringent requirements of high-speed highways, high-speed railways, and other demanding projects.

High-hardness rocks such as granite, basalt, river pebbles, and diabase (compressive strength ≥150MPa)

• 0-5mm (high-quality manufactured sand, with controllable powder content)

• 5-10mm (small and medium-sized aggregates)

• 10-20mm (commonly used main specification)

• 20-31.5mm (large-sized aggregates, customizable)

• Primary crushing: C100 jaw crusher (high feed opening, suitable for large granite blocks)

• Secondary crushing: Dual CS160 cone crushers in parallel (laminated crushing principle, high efficiency and energy saving)

• Screening system: 3 sets of 2YK1860 vibrating screens (multi-layer classification, high precision)

• Control system: PLC automation + central monitoring large screen

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!