Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

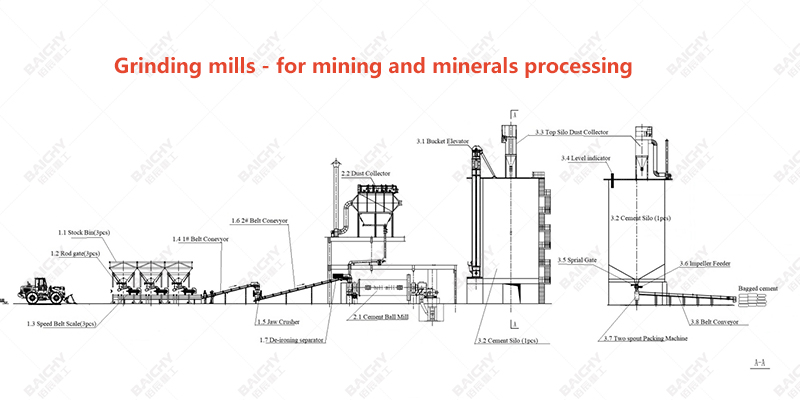

As the core grinding equipment for medium- to large-scale mineral processing plants, the 1830x4500 ball mill has attracted considerable attention for its stable performance and impressive output.

The 1830x4500 ball mill is an ideal choice for medium- to large-scale grinding production lines. It balances investment costs with production efficiency, creating substantial economic value for users. If you are looking for reliable and efficient grinding equipment for your project, the 1830x4500 ball mill is undoubtedly an option worthy of high consideration.

The 1830x4500 ball mill's operating principle is classic and efficient:

A motor drives the drum through a reducer to slowly rotate. The drum contains grinding media (steel balls or steel segments) and the material to be ground. As the drum rotates, the grinding media is lifted to a certain height by friction and centrifugal force, then falls or cascades. During this process, the material is subjected to the combined impact of the media and the grinding force, breaking it down from lumps to the desired powder size.

Ball mill cylinder

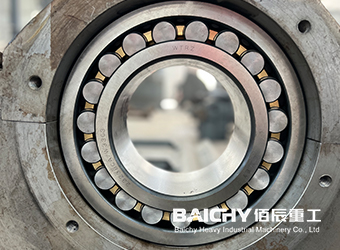

Ball mill bearing

Ball mill liner

Grinding media steel balls

| Model | Ф1830×4500 |

|---|---|

| Cylinder Rotating Speed (r/min) | 25.4 |

| Ball weight(t) | 15 |

| Feeding Size(mm) | ≤25 |

| Discharging Size(mm) | 0.074-0.4 |

| Capacity(t/h) | 4.5-12 |

| Power(kw) | 155 |

Prices vary significantly, primarily depending on:

• Equipment configuration: Are you purchasing just the main unit, or a complete system that includes a motor, reducer, electrical control system, feeder, and discharge device?

• Manufacturing process and materials: The thickness of the cylinder steel plate, gear machining accuracy, and liner material (high-manganese steel, wear-resistant alloy steel, etc.) directly affect the equipment's lifespan and price.

• Brand and after-sales service: Well-known brands are generally more expensive, but their quality and after-sales service are more guaranteed.

• Market supply and demand: Fluctuations in the prices of raw materials such as steel can also affect the final quote.

• Lubrication is key: Regularly check the lubrication of the main bearings, reducer, and gears, and add or replace qualified lubricants promptly. • Bolt Tightening: Regularly check the bolts connecting the cylinder, liner, and end cap for looseness to prevent accidents.

• Uniform Feeding: Maintain uniform and continuous feeding to avoid "empty grinding" or "full grinding" to ensure grinding efficiency and protect the equipment.

• Troubleshooting Abnormal Noise: Listen carefully during operation. If any unusual banging sounds are heard, stop the machine immediately for inspection. This may indicate a loose liner or insufficient steel balls.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.