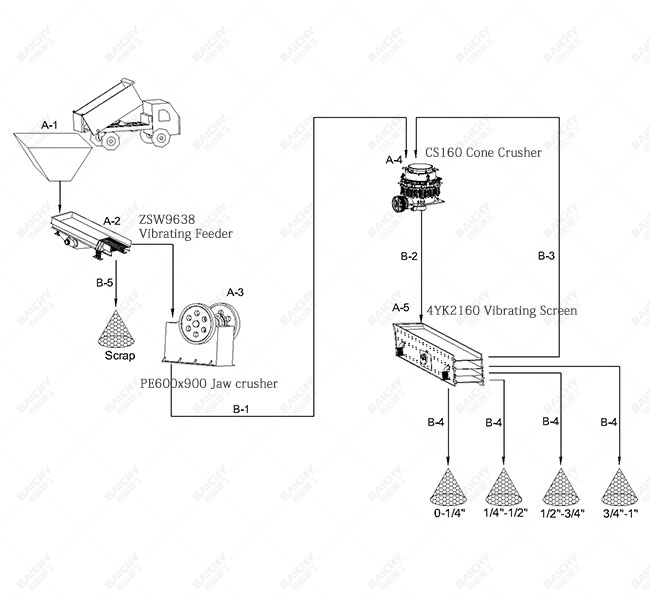

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW960X3800 | 1 |

| A-3 | Jaw Crusher | PE600X900 | 1 |

| A-4 | Cone Crusher | CS160 | 1 |

| A-5 | Vibrating Screen | 4YK2160 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B800 | 18m | 1 |

| B-2 | B800 | 25m | 1 |

| B-3 | B650 | 27m | 1 |

| B-4 | B500 | 20m | 4 |

| B-5 | B500 | 15m | 1 |

In sand and gravel aggregate production, mining crushing, and large-scale infrastructure projects, a 120-150 tons/hour aggregate crushing production line is the ideal choice for achieving a balance between efficiency and profitability in medium-scale operations. Facing the high challenges of hard rock crushing and increasingly stringent environmental and energy consumption requirements, how can you configure a production line that is both stable, high-yielding, energy-efficient, and environmentally friendly?

We provide mature and reliable complete line solutions, specifically designed for medium-to-high hardness rocks such as granite, basalt, and limestone, helping you achieve maximum return on investment with optimal investment.

• Optimized process for hard rock ensures a stable output of 120-150 tons of qualified aggregate per hour, with strong resistance to fluctuations.

• Guarantees the continuity of material supply for the project and ensures production targets are met on time.

• The core uses the CS160 cone crusher's layered crushing principle, combined with a system energy-saving design, reducing overall power consumption by 15-20%.

• Significantly reduces per-ton production costs and increases profit margins.

• 4YK2160 four-layer precision screening produces various specifications of aggregates such as 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm, with low needle-like and flaky content.

• Finished products meet high standards (such as GB/T 14685), resulting in higher selling prices and strong market competitiveness.

We reject "equipment stacking" and advocate "system matching." The following is a golden configuration combination verified by hundreds of projects:

• Role: The "pioneer" of the production line, undertaking the most demanding primary crushing task.

• Features: Large feed opening (≤500mm), strong crushing force, robust and durable structure, creating optimal conditions for subsequent crushing.

• Role: The "core" of the production line, determining the final output, particle shape, and energy consumption.

• Features: Laminated crushing principle, excellent particle shape; hydraulic discharge opening adjustment, one machine meets multiple specifications; wear-resistant design to handle hard rock abrasion.

• Role: The "quality inspector" of the production line, ensuring accurate classification of finished products.

• Features: Four-layer screen, capable of simultaneously screening 4-5 different specifications of aggregates; high screening efficiency and large processing capacity; sealed and dustproof, environmentally friendly and clean.

• ZSW490×130 Vibrating Feeder: Uniform and stable feeding, protecting the jaw crusher, the first guarantee for efficient production.

• Belt Conveyor System: Fully enclosed design, dustproof and leak-proof, connecting various process links.

Customer Pain Points: The original production line had low capacity (approximately 80 tons/hour), many flaky finished products, and high power consumption.

Our Solution: We adopted the above-mentioned "jaw crusher + cone crusher + four-layer screen" core configuration for the upgrade.

• Capacity: Steadily increased to 130 tons/hour.

• Finished Product Quality: High-quality aggregates of 5-31.5mm accounted for 85%, and the particle shape was recognized by concrete companies.

• Economic Benefits: The overall power consumption of the equipment was reduced by 15% year-on-year, saving over 300,000 yuan in electricity costs annually.

This article provides a detailed analysis of a 120-150 tons/hour aggregate rock crushing solution for medium-sized sand and gravel aggregate production, mining crushing, and infrastructure projects. The solution adopts a highly efficient combination of "jaw crusher + cone crusher + four-layer vibrating screen," specifically designed for hard rocks such as granite and basalt, achieving stable high output, energy saving, and optimized finished product particle shape. It covers equipment configuration, process flow, application scenarios, and successful case studies to help you build a high-return production line. Get your exclusive solution and investment return analysis now!

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!