Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

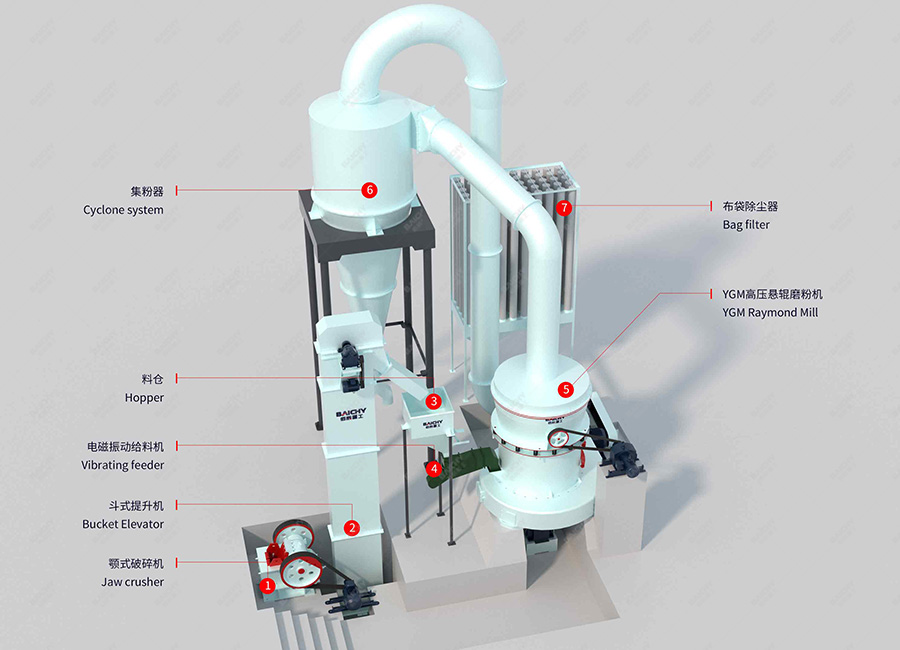

The YGM95 high-pressure mill is an innovative development based on the R-type Raymond mill. By increasing the grinding pressure of the grinding rollers, it significantly improves grinding efficiency and product fineness. It is particularly suitable for grinding hundreds of materials with a Mohs hardness of up to 9.3 and a moisture content of less than 6%, such as limestone, calcite, barite, feldspar, talc, and marble.

1. Efficient Grinding, Increased Output: The addition of a high-pressure spring increases the grinding force of the grinding rollers by 800-1200 kg. Under equivalent power and fineness conditions, the output is 10%-20% higher than that of traditional Raymond mills.

2. Energy Saving and Environmental Protection, Cost Reduction and Efficiency Improvement: Utilizing a highly efficient pulse dust removal device, dust emission concentrations are significantly below national environmental standards. The equipment's low operating power consumption effectively reduces users' long-term operating costs.

3. Adjustable Finished Product Particle Size, Excellent Quality: The finished product particle size range is flexible, ranging from 0.613 mm (30 mesh) to 0.033 mm (425 mesh), with some materials even reaching 600 mesh. The finished product has a high screening rate and uniform particle shape.

4. Stable Operation, Durability and Reliability: Core components such as the grinding rollers and grinding rings are cast from high-quality wear-resistant materials and treated with a special process for exceptional wear resistance, resulting in a low failure rate and a long service life.

5. High Level of Automation: Utilizing a centralized electrical control system, the workshop can operate unmanned, simplifying operation and maintenance.

| YGM95 MILL QUOTATION | |||

|---|---|---|---|

| Line | Description | Model | Power (KW) |

| 1 | Grinding Mill | YGM95 | Control Cabinet |

| 2 | Fine Jaw Crusher | PE250x400 | 15 |

| 3 | Hopper | 1.5 | |

| 4 | Bucket Elevator | TH200x6.5 | 3 |

| 5 | Belt Feeder With VFD | B500x4M | 3 |

| 6 | Main Unit | — | 110 |

| Classifier | 22 | ||

| Blower | 90 | ||

| Cyclone Collector With Connect Pipes |

0 | ||

| Discharge value | 1.5 | ||

| Bag Filter | |||

| 7 | Control Cabinet | 0 | |

A: The main differences lie in grinding pressure and performance. The YGM95 is an upgraded version of the Raymond mill. It incorporates a high-pressure spring device, significantly increasing the grinding force of the grinding rollers on the material. This results in higher yields, finer finished product fineness, and longer wear-resistant component life for the same material, making it particularly suitable for grinding slightly harder materials.

A: The YGM95 high-pressure mill is suitable for non-metallic minerals with a Mohs hardness of up to 9.3. Commonly processed materials include limestone, calcite, barite, potassium feldspar, talc, marble, and ceramics. However, it is not recommended for grinding high-hardness materials such as metals.

A: The YGM95 offers a wide range of particle sizes, typically between 0.613 mm (30 mesh) and 0.033 mm (425 mesh). With the addition of a precision analyzer, the finest powder size for some materials can even reach 600 mesh. This allows for flexible adjustments based on your final product specifications.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.