Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

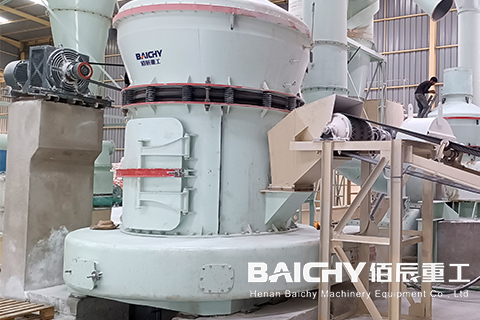

In powder processing processes in the mining, building materials, and chemical industries, an efficient and reliable grinding machine is the heart of the production line. As a classic and mature grinding equipment, the industrial YGM Raymond Millhas always held a key position with its stable performance and wide adaptability.

The operating principle of the YGM Raymond Mill can be summarized as "three-dimensional structure, circular flow grinding."

Its core process is as follows:

1. Feeding and Grinding: After initial crushing in a jaw crusher, lump or granular materials are conveyed by an elevator to a storage hopper. From there, they are fed evenly and quantitatively into the mill body via a feeder. The materials are crushed between the grinding rings and grinding rollers.

2. Analysis and Sorting: The crushed powder is lifted by the fan airflow and fed to the analyzer located above the mill. Coarse powder that does not meet the fineness requirements is removed by the analyzer blades and returned to the grinding chamber for re-grinding. Fine powder that meets the required fineness is carried by the airflow into the powder collection system.

3. Product Collection: The dust-laden airflow enters a high-efficiency cyclone collector, where the majority of the finished powder is separated by centrifugal force and gravity. The finished powder is then discharged through a discharge valve.

This closed-loop system enables continuous automated production and precisely controls the fineness of the finished product by adjusting the analyzer speed.

| Model |

Roller (pcs) |

Roll Dia. (mm) |

Roll Ring Size (mm) |

Max. Input Size (mm) |

Output Size (mm) |

Capacity t/h |

Power (Kw) |

Dimension (mm) |

| 3R2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 0.4-1 | 15 | 3500*3300*4500 |

| 3R2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 0.5-2 | 18.5 | 4650*3600*5100 |

| 3R2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 0.8-3 | 22 | 4700*3600*5100 |

| 4R3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 1-4 | 30 | 5400*4100*5200 |

| 4R3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 1.8-4.5 | 37 | 7100*5900*7900 |

| 5R4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 2.5-9.5 | 75 | 9200*7250*9700 |

A: The standard YGM Raymond Mill is primarily suitable for medium-fine powder grinding, with an effective product fineness range typically between 80 and 600 mesh. For ultrafine powders of 800, 1000, or even finer, standard YGM models are not directly capable of achieving this. If finer mesh sizes are required, consider configuring a more efficient separator or opting for a specially designed ultrafine vertical mill.

A: This is a very common question, but it's difficult to generalize. The price of a YGM Raymond Mill is influenced by many factors, ranging from hundreds of thousands to over a million RMB. It primarily depends on:

• Model size: This is the most important factor; models with larger outputs command higher prices.

• Configuration level: For example, the type of dust collector (pulse bag filter or standard dust collector), and whether auxiliary equipment such as feeders and elevators are included.

• Material requirements: Whether material-contacting parts require special wear-resistant steel, which affects cost and lifespan.

• Supplier differences: Different manufacturers have different pricing strategies and after-sales service costs.

The most accurate way to determine your requirements is to provide suppliers with your specific material, production volume, and fineness requirements to obtain a tailored quote.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.