Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

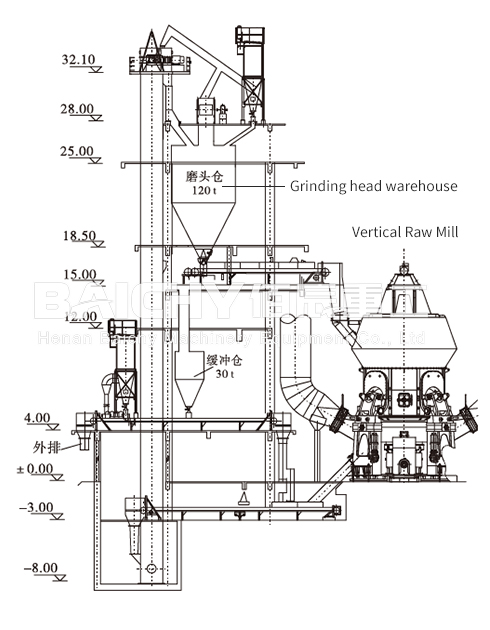

In heavy industries like cement and metallurgy, raw material grinding is one of the most energy-intensive processes. Choosing efficient and energy-saving grinding equipment directly impacts a company's production costs and market competitiveness. As a core component of modern grinding technology, vertical raw material mills (vertical mills) are becoming the preferred choice for industry upgrades due to their superior performance.

Compared to traditional ball mills, vertical raw material mills offer groundbreaking innovations in their operating principle. They utilize a material bed grinding principle, crushing materials through rolling and shearing. This offers several significant advantages:

1. Extremely Low Energy Consumption: They consume 30%-50% less electricity than ball mills, significantly reducing operating costs.

2. High Grinding Efficiency: Material residence time in the mill is short, making it easier to control powder fineness and gradation.

3. Small Footprint: The vertical mill's compact structure significantly reduces plant construction and land investment. 4. Low noise and good environmental protection: Low noise during operation, the system is overall sealed, and dust leakage is minimal.

Step 1: Feeding and Leveling

Raw material is evenly fed into the vertical mill via a belt conveyor and lands on the center of the rotating grinding disc. Centrifugal force rapidly spreads the material, forming a uniformly thick material bed, paving the way for efficient grinding.

Step 2: Grinding and Drying

Grinding: The grinding disc drives the material bed over the grinding rollers. Under pressure provided by the hydraulic system, the material is crushed and pulverized, achieving high-efficiency and low-energy grinding.

Drying: High-temperature hot air introduced from the bottom of the mill creates an upward airflow in the grinding zone, simultaneously drying the material while grinding, effectively integrating the two processes.

Step 3: Elevation and Preliminary Selection

The crushed material is carried upward by hot air to the separation area. During this process, fine particles rise with the airflow, while coarse particles fall back to the grinding discs due to gravity for further grinding, completing the initial separation.

Step 4: Dynamic Separation

After the material enters the high-speed rotating classifier:

Fine powder: Subjected to less centrifugal force, it passes through the classifier with the airflow to become a qualified finished product.

Coarse powder: Subjected to greater centrifugal force, it is thrown to the edge of the classifier and falls back to the grinding discs for further grinding.

Step 5: Finished Product Collection

The airflow containing fine powder enters the dust collector for gas-solid separation. The finished fine powder is collected and transported to the finished product storage, and the purified air is discharged through a fan.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

A: This is the key design feature of a vertical mill. During operation, high-temperature hot air (from a source such as kiln exhaust or a hot air furnace) is introduced from the bottom. This hot air creates a powerful upward airflow within the mill. As the material is crushed by the grinding discs and rollers, the hot air directly penetrates the material bed, instantly evaporating moisture from the material, thereby achieving simultaneous grinding and drying.

A: The vertical mill utilizes a dynamic powder selector. The principle is that the crushed material is blown toward the high-speed rotating rotor at the top by air. Fine powder is subjected to less centrifugal force and is carried through the airflow to become the finished product. Coarse powder is subjected to greater centrifugal force and is ejected, returning to the grinding discs for re-grinding. This "internal circulation" mechanism ensures that only qualified products are discharged, avoiding energy waste from over-grinding, thereby significantly improving grinding efficiency.

A: The main influencing factors include:

Material properties: Material grindability, inlet moisture content, and particle size.

Equipment operation: Proper matching of roller pressure, classifier speed, air volume, and air temperature.

Wear: The degree of wear on the grinding roller and grinding plate directly affects grinding efficiency.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.