Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

GGBS (Ground Granulated Blast Furnace Slag) is hailed as the "green engine" of sustainable development in the construction industry. It cleverly connects the two energy-intensive industries of steel and cement, building a green industry chain focused on resource recycling and providing critical support for the construction of stronger, more durable, and environmentally friendly structures.

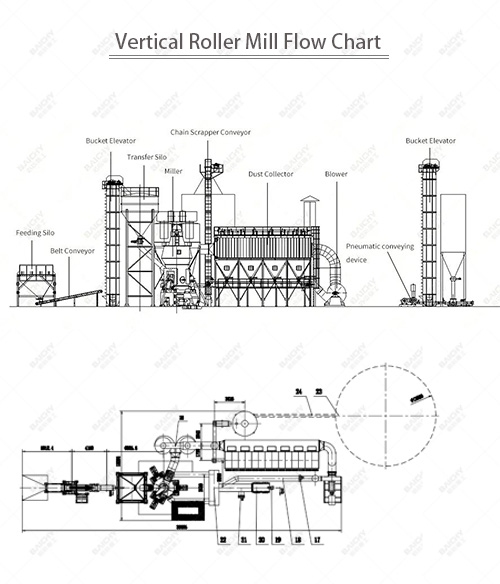

The performance of GGBS is highly dependent on its quality, particularly the fineness and particle size distribution of the finished product. The GGBS vertical roller mill (also known as a slag mill) is the core equipment for producing high-quality GGBS. Integrating crushing, grinding, drying, separation, and conveying functions, this equipment can transform high-moisture granulated blast furnace slag into high-quality, standard-compliant fines in a single process. The finished product boasts a specific surface area exceeding 4200-4500 cm²/g, making it an indispensable key component in modern GGBS production lines.

With its efficient grinding, low energy consumption, and stable operation, the GGBS vertical roller mill not only ensures the excellent activity of the fines produced but also actively promotes the high-quality development of the entire green building materials industry.

• High Strength and Long-Lasting Performance

• Excellent Durability

• Improved Construction and Appearance

The gelling activity of GGBS is highly dependent on the fineness and particle size distribution of the finished powder.

The GGBS vertical roller mill (also known as a slag vertical mill) is a large-scale machine designed specifically for slag grinding. It integrates crushing, grinding, drying, classifying, and conveying, capable of grinding high-moisture granulated blast furnace slag into high-quality ore powder that meets standard requirements (with a specific surface area of 4200-4500 cm²/g or more) in one operation. It is the core unit of a modern GGBS production line.

The operating principle of the vertical roller mill is scientific and efficient:

1. Feeding and Drying: The material is fed into the mill through an air-locked feeder and lands on the center of the rotating grinding disc. Simultaneously, hot air is introduced from the edge of the grinding disc, instantly drying the material.

2. Roller Grinding: Centrifugal force throws the material onto the grinding disc track. Grinding rollers mounted on the grinding disc, operated by a hydraulic system, crush the material bed. This is the "bed grinding" principle, which offers extremely high energy efficiency.

3. Sorting and Collection: Hot air carries the crushed fine powder into the dynamic classifier above the mill for sorting. Qualified fine powder exits the mill with the airflow and is collected by the dust collector as the finished product. Unqualified coarse powder falls back onto the grinding discs for re-grinding.

This integrated design streamlines the process and significantly reduces energy consumption compared to traditional ball mill systems.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

A: The core advantages of the vertical roller mill lie in its high energy efficiency and integration. It utilizes the "charge bed grinding" principle, resulting in high energy efficiency and overall power consumption that is 30%-50% lower than traditional ball mill systems. Furthermore, it integrates grinding, drying, and separation into a single unit, resulting in a streamlined process and a compact footprint. It can also effectively process slag with a high moisture content.

A: The GGBS vertical roller mill has a powerful built-in drying function and can directly process granulated blast furnace slag with a moisture content of up to 15%-20%. Hot air is introduced from the bottom of the mill, drying the slag during the grinding process, eliminating the need for a separate drying unit and reducing system investment and operating costs.

A: Finished product fineness is primarily achieved by adjusting the speed of the dynamic concentrator located on top of the mill. This is simple to operate and offers a wide adjustment range. Typically, the surface area of the finished product can be flexibly controlled between 3800 and 5500 cm²/g to meet the specific activity requirements of different customers.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.