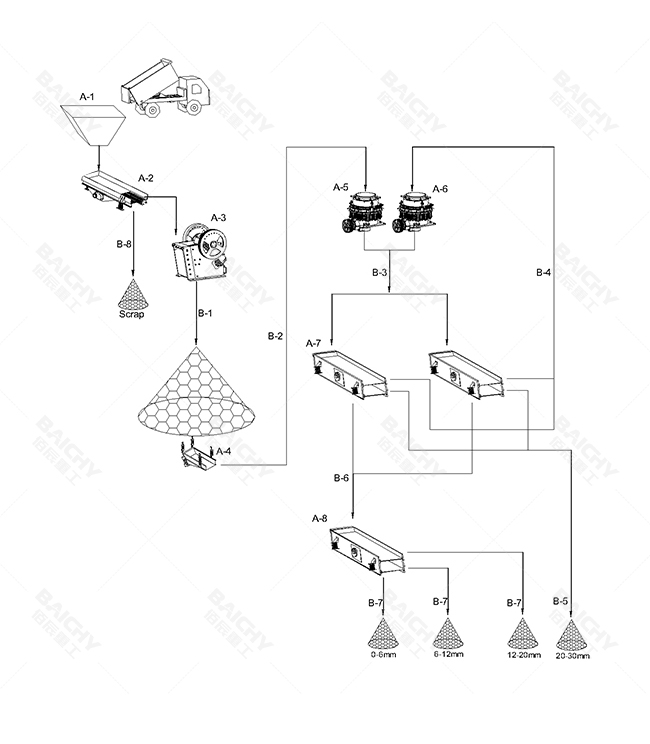

Project address: Tajikistan

Project capacity: 300tph

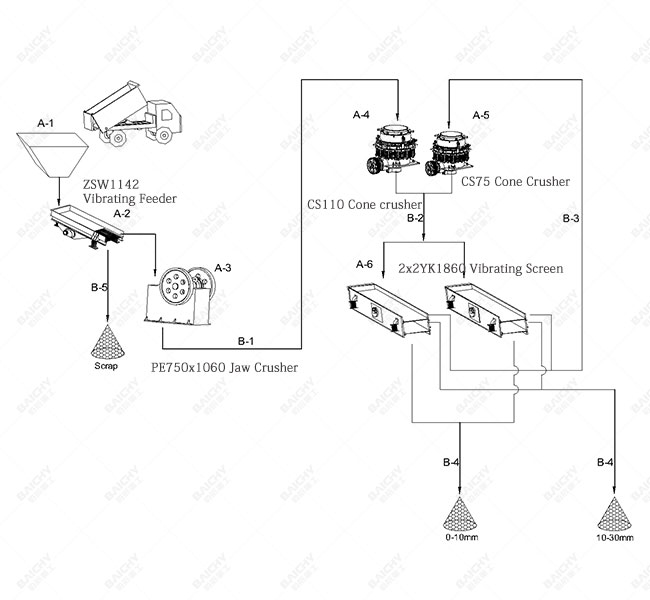

Project address: Mexico

Project capacity: 200-300tph

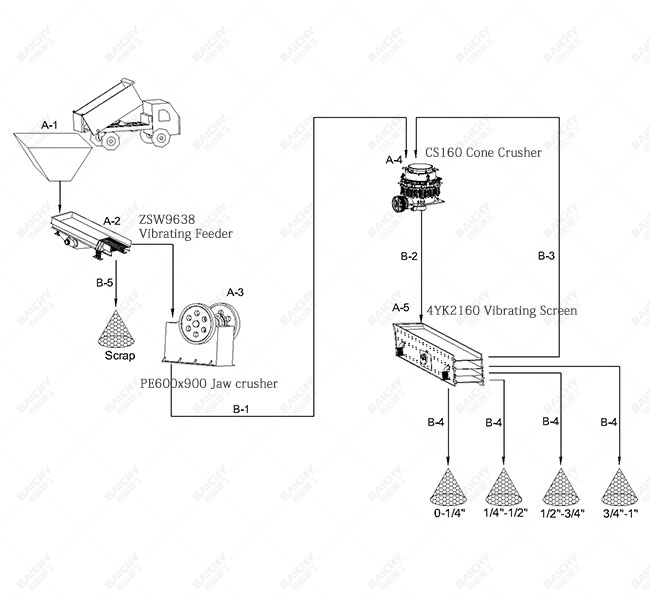

Project address: Somalia

Project capacity: 150-200tph

Project location: Russia

Project capacity: 100-180tph

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1100X4200 | 1 |

| A-3 | Jaw Crusher | C100 | 1 |

| A-4 | Vibrating Feeder | GZG-300 | 1 |

| A-5 | Cone Crusher | CS160 | 1 |

| A-6 | Cone Crusher | CS160 | 1 |

| A-7 | Vibrating Screen | 2YK1860 | 2 |

| A-8 | Vibrating Screen | 2YK1860 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1000 | 30m | 1 |

| B-2 | B1000 | (25+8)m | 1 |

| B-3 | B1000 | (26+8)m | 1 |

| B-4 | B800 | (24+8)m | 1 |

| B-5 | B650 | (20+8)m | 1 |

| B-6 | B800 | (21+8)m | 1 |

| B-7 | B650 | 20m | 3 |

| B-8 | B650 | 15m | 1 |

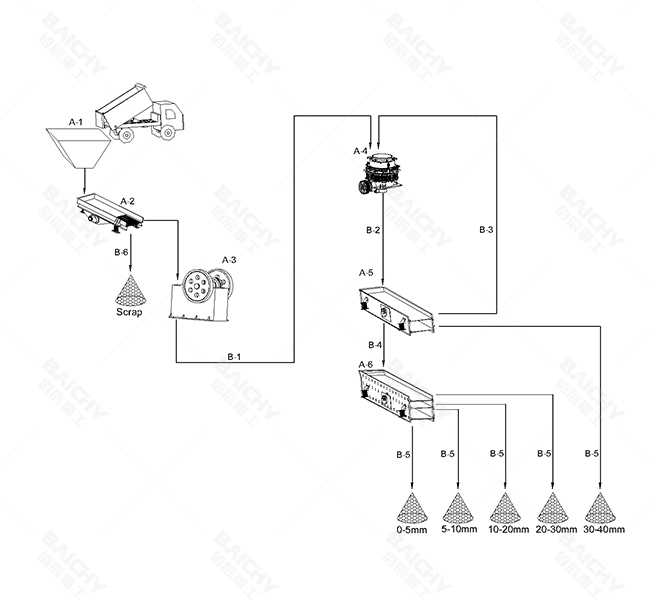

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1100X4200 | 1 |

| A-3 | Jaw Crusher | PE750X1060 | 1 |

| A-4 | Cone Crusher | CS160 | 1 |

| A-5 | Cone Crusher | CS75 | 1 |

| A-6 | Vibrating Screen | 2YK1860 | 2 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1000 | 23m | 1 |

| B-2 | B1000 | (21+8)m | 1 |

| B-3 | B650 | (23+8)m | 1 |

| B-4 | B650 | (25+8)m | 2 |

| B-5 | B500 | 15m | 1 |

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW960X3800 | 1 |

| A-3 | Jaw Crusher | PE600X900 | 1 |

| A-4 | Cone Crusher | CS160 | 1 |

| A-5 | Vibrating Screen | 4YK2160 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B800 | 18m | 1 |

| B-2 | B800 | 25m | 1 |

| B-3 | B650 | 27m | 1 |

| B-4 | B500 | 20m | 4 |

| B-5 | B500 | 15m | 1 |

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW960X3800 | 1 |

| A-3 | Jaw Crusher | PE600X900 | 1 |

| A-4 | Cone Crusher | CS110 | 1 |

| A-5 | Vibrating Screen | 2YK1860 | 1 |

| A-6 | Vibrating Screen | 3YK1848 | 1 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B800 | 18m | 1 |

| B-2 | B800 | 21m | 1 |

| B-3 | B650 | 23m | 1 |

| B-4 | B650 | 23m | 1 |

| B-5 | B500 | 15m | 5 |

| B-5 | B500 | 10m | 1 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Objective: To gain a deep understanding of needs, provide optimal solutions, and build professional trust.

• Technical Consultation: Experienced sales engineers or application experts will engage in in-depth communication with clients regarding production processes, material characteristics, capacity targets, and existing pain points.

• On-site Survey: On-site service will be provided when necessary to assess the client's production environment, spatial layout, and supporting facilities, ensuring the feasibility of the solution.

• Equipment Selection Recommendations: Based on material characteristics (hardness, moisture, particle size, composition, etc.) and product requirements (output fineness, capacity, shape), the most suitable crushing, grading, and testing equipment models will be recommended.

• Process Design: Customized process flow diagrams and equipment layout diagrams will be provided to ensure the production line is efficient, stable, and environmentally friendly.

• Benefit Analysis and Report: Detailed input-output analysis will be provided, clearly demonstrating the value brought by equipment upgrades or the construction of new production lines, including efficiency improvements, energy reductions, and quality improvements.

• Free Laboratory Trial Grinding: Invite customers to send samples or conduct free testing at Baichen's laboratory. Verify the solution with actual grinding/classification results, letting the data speak for itself.

• Test Report Provision: Provide detailed test reports, including processing procedures, result data, particle size distribution diagrams, and professional analysis recommendations.

Objective: Ensure smooth equipment installation and commissioning, and complete technology transfer for the customer's team.

• Transparent Progress Tracking: Provide updates on order confirmation, production plans, and key milestones (such as pre-shipment testing).

• Pre-Acceptance: Invite customers to the factory for pre-shipment acceptance testing to ensure the equipment meets technical agreement requirements.

• Comprehensive Installation Plan: Provide detailed installation foundation drawings, a list of water, electricity, and steam requirements, and dispatch professional engineers to provide on-site installation guidance.

• Systematic Debugging: Engineers conduct on-site debugging of individual equipment, integrated debugging, and production with materials, optimizing operating parameters until the contractually agreed technical specifications (capacity, fineness, energy consumption, etc.) are met.

• On-site Training: Hands-on on-site training is provided to the customer's operation and maintenance personnel to ensure they can operate the equipment independently, safely, and correctly, and handle common problems.

• A complete technical documentation package is provided, including equipment manuals, electrical schematics, maintenance manuals, spare parts lists, etc.

Objective: To ensure long-term stable operation of the equipment, continuously create value, and deepen the partnership.

• Multi-channel Support: Providing multi-channel technical support including 400 telephone, WeChat, and online customer service, with 24/7 emergency response.

• Remote Diagnosis: Remote fault diagnosis and guidance are provided via telephone, video, etc., to quickly resolve common problems.

• Original Equipment Spare Parts Warehouse: Ensuring sufficient original equipment spare parts inventory to guarantee rapid supply and reliable quality.

• Planned Maintenance: Providing regular inspections and preventative maintenance services to proactively identify and eliminate potential hazards, reducing unplanned downtime.

• Emergency On-Site Service: For major issues that cannot be resolved remotely, we promise to dispatch engineers to the site within the agreed timeframe.

• Process Optimization Consulting: Providing continuous process optimization suggestions as customers upgrade their products or change raw materials.

• Equipment Upgrades and Retrofits: Providing services such as equipment performance upgrades and intelligent transformation (e.g., integration with SCADA/MES systems) to help customers' production lines keep pace with the times.

• Customer Follow-up and Satisfaction Surveys: Regular follow-ups to understand equipment operating status, collect improvement suggestions, and enhance customer experience.

Baichy's core advantage lies in its ability to provide customized crushing and screening solutions tailored to each customer's raw stone characteristics (hardness, abrasiveness, mud content, etc.) and finished product requirements (particle size, shape, gradation). This ensures optimal production line configuration and smoothest processes, achieving higher production efficiency from the source, rather than simply piecing together equipment.

The core crushers in the production line (such as jaw crushers, cone crushers, and impact crushers) typically employ heavy-duty designs, high-quality alloy wear-resistant parts, and advanced crushing chamber designs. This guarantees high output, low failure rate, and excellent particle shape control under continuous high-intensity operation, effectively reducing production and maintenance costs per unit output.

Modern Baichy production lines generally integrate a central PLC automatic control system, enabling one-button start/stop, online monitoring, fault alarms, and intelligent adjustment. Meanwhile, the entire process from feeding to finished product discharge is systematically integrated with dust removal, sealing, noise reduction and circulating water systems to ensure that the production line operates efficiently while meeting increasingly stringent environmental protection requirements and achieving green production.

The core competitiveness of modern, advanced stone crushing production lines has evolved from focusing solely on equipment performance to competing on systemic solutions. The key to success lies in achieving the optimal balance between efficiency, cost, and compliance.

A first-class stone crushing production line is essentially a customized production system. It ensures optimal solutions through customized design, guarantees stable operation through intelligent control, and ultimately maximizes economic and social benefits within a green framework, thus building a strong competitive advantage in the fierce market.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!