Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In the sand and gravel aggregate industry, the choice of sand making machine directly impacts production efficiency, product quality, and operating costs. While traditional sand making equipment (such as hammer crushers and roller crushers) offers lower costs, they often suffer from rapid wear, poor finished product particle shape, and high energy consumption. The VSI7611 vertical shaft impact crusher, with its unique operating principle and optimized design, is becoming the preferred equipment for medium- and large-scale sand and gravel plants.

The VSI7611 utilizes a dual-mode crushing mechanism: "rock on rock" and "rock on iron." The high-speed rotating impeller drives the material into collision, rather than relying solely on wear and tear. This results in:

• The finished sand particle shape is more rounded (<5% needle-like flake content), meeting the requirements of high-standard construction sand (e.g., C30 and above concrete aggregate).

• It reduces over-crushing, increasing the proportion of fine sand (0.3-5mm), and increasing sales premiums.

Traditional sand making machines require frequent replacement of vulnerable parts (such as hammers and liners). The VSI7611 utilizes:

• Modular wear blocks: Adjustable for use, extending life by 2-3 times.

• Hydraulic cover opening device: Quickly replace core components without a crane, reducing downtime by 70%.

• Variable frequency control technology: Automatically adjusts speed based on material hardness, reducing energy consumption by 15%-20% compared to similar equipment.

• Enclosed structure + pulse dust removal: Dust emissions <20mg/m³, easily passing environmental inspections.

| Model | VSI-7611 | |

|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 120-180 |

| Center Feeding | 60-90 | |

| Feeding Size (mm) | Soft Material | <35 |

| Hard Material | <30 | |

| Rotation Speed (r/min) | 1700-1890 | |

| Power of the Double Motors (kw) | 110-150 | |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | |

| Power Source | 380v:50hz | |

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw |

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |

| Overall Dimension L*W*H (mm) | 820x520x1270 | |

| Power of Oil-Box Heater | 2kw | |

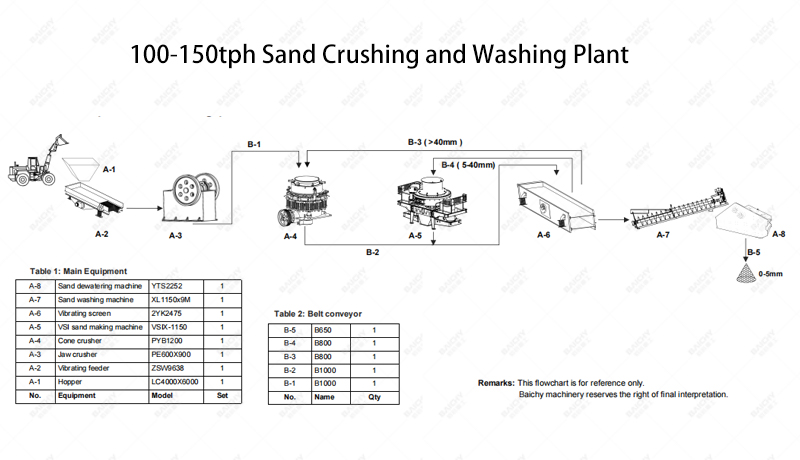

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating Feeder | ZSW9638 | 1 |

| 3 | Jaw Crusher | PE600x900 | 1 |

| 4 | Cone Crusher | PYB1200 | 1 |

| 5 | Sand Making Machine | VSI 7611 | 1 |

| 6 | Vibrating Screen | 2YK2470 | 1 |

| 7 | Sand Washing Machine | XL1150×9M | 1 |

| 7 | Sand Dewateing machine | YTS2252 | 1 |

| 7 | Belt Conveyor | B1000 | 2 |

| 8 | Belt Conveyor | B800 | 2 |

| 9 | Belt Conveyor | B650 | 1 |

Granite is a highly hard rock (Mohs hardness 6-7), and traditional sand-making equipment faces three major challenges: rapid wear, high energy consumption, and poor finished product particle shape. However, a 100-150 t/h production line equipped with the VSI7611 sand-making machine, through vertical shaft impact crushing and intelligent grading, achieves a balance of high output, low loss, and excellent quality.

• Pre-installed cone crusher: Crushes granite to ≤30mm, reducing impact pressure on the VSI7611 impeller and extending the life of wear parts by 40%.

• Air screening system (optional): Separates stone powder below 0.075mm, improving the gradation of the finished sand.

The VSI7611 sand making machine demonstrates outstanding performance and cost-effectiveness in a 100 t/h granite production line, making it an ideal choice for medium-sized sand and gravel plants. For detailed technical proposals or site visits, please feel free to contact us.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!