Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In the manufactured sand industry, the choice of sand-making machine directly impacts production efficiency, finished product quality, and operating costs. The VSI-1145 sand making machine, a classic vertical shaft impact crusher, has become the preferred equipment for medium- and large-scale sand and gravel plants thanks to its high crushing ratio, low energy consumption, and intelligent maintenance.

• Deep-cavity rotor design: Optimizes material throughput and increases crushing efficiency by 20%, maintaining high sand production output even for hard rocks like granite and basalt.

• Hydraulically adjustable discharge: Adjustable finished sand size from 0-5mm, with controllable fineness modulus, meeting various construction sand standards (such as C30 concrete sand).

• Composite polishing head: Made of high-chromium alloy + tungsten carbide coating, it offers a 50% longer lifespan than ordinary alloys, reducing replacement frequency.

• Hydraulic cover opening: Maintenance requires no housing removal, allowing a single person to inspect and repair core components, reducing downtime by 70%.

• Pulse dust removal interface: Directly connects to dust removal equipment, ensuring dust emissions ≤ 20mg/m³, easily passing environmental inspections.

• Variable frequency drive system: Saves 15%-30% more energy than traditional motors, with energy consumption as low as 1.2kW·h per ton of sand.

| Model | VSI-1145 | |

|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 490-600 |

| Center Feeding | 250-310 | |

| Feeding Size (mm) | Soft Material | <50 |

| Hard Material | <45 | |

| Rotation Speed (r/min) | 1180-1280 | |

| Power of the Double Motors (kw) | 440-520 | |

| Overall dimension L*W*H (mm) | 5100*2790*3320 | |

| Power Source | 380v:50hz | |

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw |

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |

| Overall Dimension L*W*H (mm) | 820x520x1270 | |

| Power of Oil-Box Heater | 2kw | |

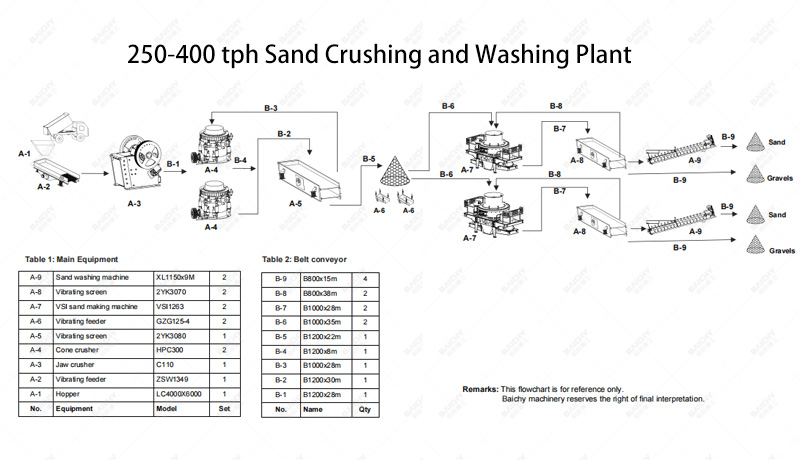

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC4000×6000 | 1 |

| 2 | Vibrating feeder | ZSW1349 | 1 |

| 3 | Jaw Crusher | C110 | 1 |

| 4 | Cone Crusher | HP300 | 2 |

| 5 | Vibrating Screen | 2YK3080 | 1 |

| 6 | Vibrating Screen | 2YK3070 | 2 |

| 7 | Sand Making Machine | VSI 1145 | 2 |

| 8 | Sand Washing Machine | XL1150×9m | 2 |

| 9 | Belt conveyor | B1200 | 4 |

| 10 | Belt conveyor | B1000 | 5 |

| 11 | Belt conveyor | B800 | 6 |

In large-scale crushing and sand-making production lines with an output of over 500 t/h, the efficiency of the sand-making process directly impacts the quality of the final product and operating costs. The VSI-1145 sand maker, with its high processing capacity (490-600 t/h), low energy consumption, and stable sand output, has become a key piece of equipment for fine crushing and sand-making in large-scale sand and gravel plants.

In a typical three-stage crushing process consisting of a jaw crusher, a cone crusher, and a sand maker, the VSI-1145 is typically located in the third stage, responsible for:

• Sand shaping: Further crushing the 20-40mm aggregate output from the cone crusher to 0-5mm machine-made sand.

• Grain shape optimization: Using a "stone-on-stone" or "stone-on-iron" process, the sand's angularity is improved, boosting concrete strength.

• A single VSI-1145 is suitable for production lines with an output of less than 300 tons per hour.

• Multiple units connected in parallel (e.g,. 3 VSI-1145 units) can meet the needs of large-scale projects with an hourly output of 800-1000 tons, and the equipment can back up each other to ensure continuous production.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!