Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The VSI8518 sand-making machine is a high-performance sand-making machine designed based on the vertical shaft impact crushing principle. It is optimized for crushing medium-hard materials such as granite, basalt, and limestone. Its unique dual crushing modes ("stone on stone" and "stone on iron") ensure uniform and well-graded finished sand, meeting the demand for high-quality manufactured sand in the construction, highway, and hydropower industries.

• High-efficiency crushing: 200-260 t/h, suitable for large-scale sand and gravel production.

• High-quality finished product: Adjustable sand fineness modulus, cubic particles, and low fines content.

• Energy-saving and environmentally friendly: The deep-cavity rotor design reduces energy consumption, and pulse dust removal reduces dust pollution.

• Easy maintenance: The hydraulic cover opening facilitates access, and key components are made of wear-resistant materials for a longer life.

Case Study: A large Indonesian building materials company uses a VSI8518 sand making machine to crush basalt into 0-3mm fine sand, increasing the efficiency of its sand and gravel production line by 30% and boosting annual profits by over US$300,000.

| Model | VSI-8518 | |

|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 200-260 |

| Center Feeding | 100-130 | |

| Feeding Size (mm) | Soft Material | <40 |

| Hard Material | <35 | |

| Rotation Speed (r/min) | 1520-1690 | |

| Power of the Double Motors (kw) | 180-220 | |

| Overall dimension L*W*H (mm) | 4140*2280*2425 | |

| Power Source | 380v:50hz | |

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw |

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |

| Overall Dimension L*W*H (mm) | 820x520x1270 | |

| Power of Oil-Box Heater | 2kw | |

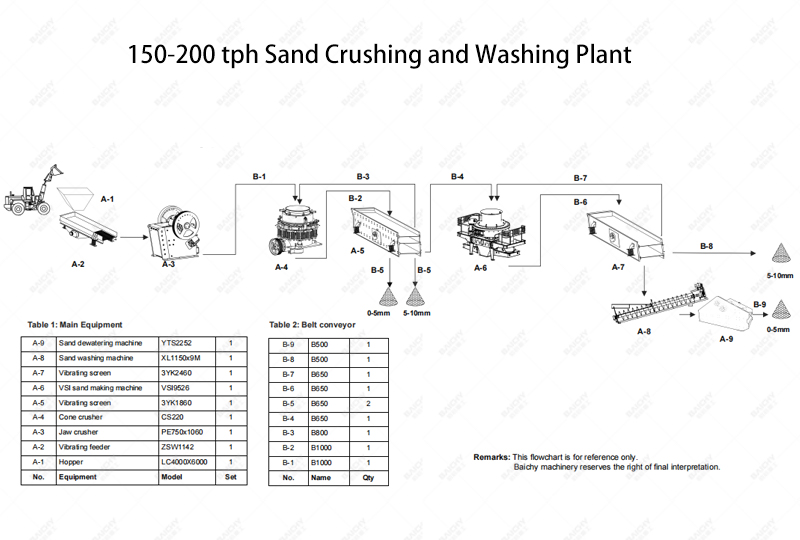

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC4000×6000 | 1 |

| 2 | Vibrating feeder | ZSW1142 | 1 |

| 3 | Jaw Crusher | PE750×1060 | 1 |

| 4 | Cone Crusher | CS220 | 1 |

| 5 | Vibrating Screen | 3YK1860 | 1 |

| 6 | Sand Making Machine | VSI 8518 | 1 |

| 7 | Vibrating Screen | 3YK2460 | 1 |

| 7 | Sand Washing Machine | XL1150×9m | 1 |

| 7 | Sand Dewatering Machine | YTS2252 | 1 |

| 7 | Belt conveyor | B1000 | 2 |

| 7 | Belt conveyor | B800 | 1 |

| 8 | Belt conveyor | B650 | 4 |

| 9 | Belt conveyor | B500 | 2 |

In sand and gravel aggregate production, the VSI8518 sand making machine, with its efficient crushing capacity and stable finished product quality, is an ideal choice for medium-to-large sand production lines with a capacity of 150 t/h.

The VSI8518 sand making machine utilizes a vertical shaft impact crushing principle and is suitable for fine crushing and sand production of medium-hard materials such as granite, basalt, and limestone.

• Fine crushing and shaping: Further crushing of coarse crushed materials ≤ 50 mm into high-quality machine-made sand with a size of 0-5 mm.>

• Grain shape optimization: Utilizing both "stone-on-stone" and "stone-on-iron" crushing modes, the finished sand is ensured to have a cubic shape and minimize needle-like and flake-like particles.

• Grading adjustment: By adjusting the rotor speed and feed rate, the fineness modulus of the sand (e.g., 2.3-3.0) can be controlled to meet the needs of different projects.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!