In the ever-evolving global infrastructure development, high-quality sand and gravel aggregates are the cornerstone of everything. As the source of all this, a high-efficiency, stable, and durable crusher directly determines the project's cost, efficiency, and ultimate benefits. Faced with a dazzling array of choices in the market, how do you identify a truly reliable partner?

Baich Heavy Industry, a leading Chinese crusher manufacturer and overall solution provider with decades of experience in the industry, is becoming the preferred choice for numerous large-scale projects worldwide thanks to its superior quality, innovative technology, and comprehensive services.

I. Core Strength: A Complete Industry Chain Advantage from Core Components to Complete Machine Production

Unlike simple equipment assembly plants, Baichy Heavy Industry boasts a modern, large-scale production base, achieving independent production throughout the entire process, from core steel casting and precision machining to complete machine assembly and commissioning. This source factory model ensures our ultimate control over every production link.

• Controllable Quality: From raw material entry to finished product delivery, a quality inspection system stricter than national standards is implemented to ensure that every piece of equipment leaving the factory is robust and durable.

• Cost Optimization: Reducing intermediaries allows us to offer customers more competitive crusher prices, achieving true "factory direct sales."

• Fast Delivery: Strong independent production capabilities ensure on-time order delivery, preventing delays in your project schedule.

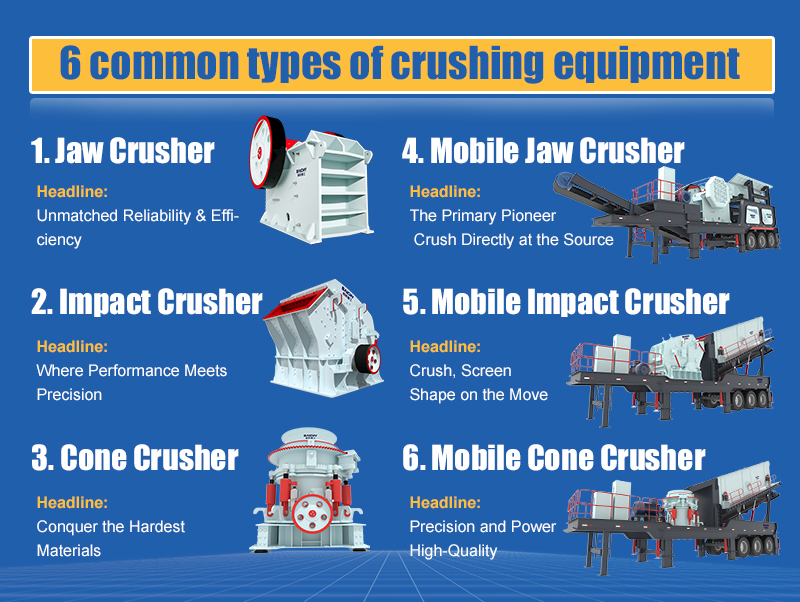

Whether it's a basic jaw crusher, a high-efficiency fine-crushing cone crusher, or a flexible mobile crushing plant, we manufacture to military-grade standards.

II. Professional Solutions: Tailor-made solutions to overcome perse crushing challenges

We understand that every project faces different ore hardness, feed size, discharge requirements, and site conditions. Therefore, XX Heavy Industry offers much more than just a single piece of equipment.

Our engineering team will tailor the best overall solution for you based on your specific needs (such as expected output, finished product particle size, investment budget, etc.). Whether it's a small sand and gravel plant with a capacity of 100 tons per hour or a large mining project with a capacity of 2000 tons per hour, we can provide the most economical and efficient turnkey projects.

• Crushing solutions for high-hardness rocks such as granite and basalt

• Crushing and sand-making solutions for medium-hardness materials such as limestone and bluestone

• Resource-based recycling solutions for construction waste

• Environmentally friendly dry sand-making production line solutions

III. Global Witness: Superior Performance, Serving Every Corner of the World

Baichy Heavy Industry's equipment has been exported to over 80 countries and regions worldwide, operating stably in numerous large-scale mines, water conservancy projects, highways, and urban construction projects in Asia, Africa, Europe, and South America. Our success stories are the best proof of our product strength.

“Choosing Baichy Heavy Industry is not just choosing a machine, but choosing a trustworthy long-term partner. Their production line solutions have greatly improved our production efficiency and reduced operating costs.” — Feedback from an overseas customer

Take action now and get your customized solution!

If you are looking for a Chinese crusher manufacturer supplier that combines quality, technology, and service, Baichy Heavy Industry is the choice you cannot afford to miss.

Please contact us immediately to obtain the following exclusive services:

1. Free equipment selection and solution design: Our experts will provide you with one-on-one service.

2. Visit our factory and customer case studies: Witness firsthand our manufacturing capabilities and the operational status of our equipment.

3. Obtain a detailed equipment quotation: Transparent pricing, clear at a glance.