What are the models of Baichy PYB series cone crushers?

Baichy PYB series cone crushers are available in various models to meet different production needs. Common models include PYB600, PYB900, PYB1200, PYB1750, PYB2200. These types of equipment are widely used in construction stone crushing, solid waste treatment, and industries such as metal and non-metal minerals, cement, construction, and sand and gravel metallurgy.

Each model of cone crusher has its specific processing capacity, feed port size, discharge particle size and other parameters. For example, the PYB-600 cone crusher usually has a production capacity of 15-25t/h, the feed opening size is 65mm, and the discharge particle size is between 12-15mm. The PYB-900 cone crusher may have greater processing capacity and wider feed opening size, and the specific parameters may vary depending on the model and configuration.

Please note that the above information is for reference only, and specific models and parameters may change due to product upgrades and customization needs. If you need more detailed information, it is recommended to contact Baichy Machinery directly.

Baichy PYB series cone crusher

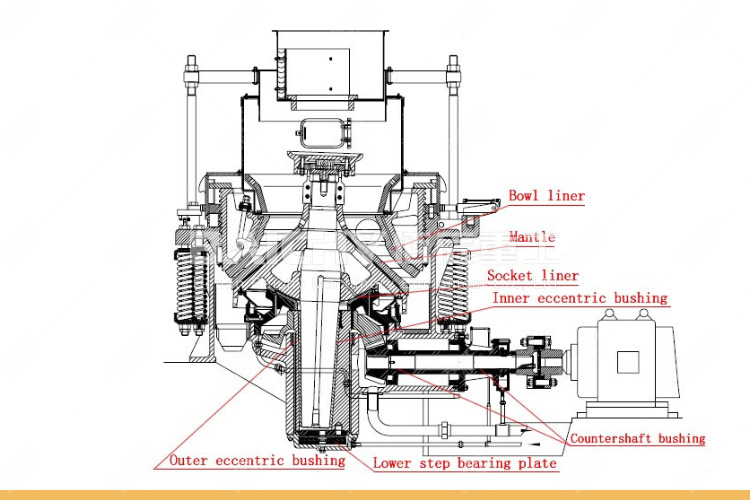

Baichy PYB series cone crusher is an efficient and stable crushing equipment, widely used in construction stone crushing, solid waste treatment, metal and non-metal minerals, cement, construction, sand and gravel metallurgy and other industries. The following are some main features of the Baichy PYB series cone crusher:

1. Efficient crushing: PYB series cone crusher adopts optimized crushing chamber shape and crushing frequency, which can efficiently crush materials to the required particle size to meet various production needs.

2. Adjustable particle size: The size of the discharge port of the equipment is adjustable, and the particle size of the crushed products can be adjusted as needed to meet the crushing requirements of different particle sizes.

3. High reliability: PYB series cone crushers use high-quality wear-resistant materials and advanced manufacturing processes to ensure stable operation of the equipment over a long period of time. At the same time, the equipment is also equipped with a dust-proof sealing structure, which effectively extends the service life of lubricating oil and parts.

4. Energy saving and environmental protection: The equipment produces less noise and dust during operation, which meets environmental protection requirements. At the same time, the equipment also adopts an energy-saving design, reducing energy consumption and operating costs.

5. Easy to maintain: The PYB series cone crusher has a reasonable structural design, making it easy to repair and replace parts. At the same time, the maintenance cycle of the equipment is longer, reducing downtime and maintenance costs.

Baichy PYB series cone crusher has a variety of models to choose from, such as PYB-600, PYB-900, PYB-1200, etc. Different models of equipment have different production capabilities and application ranges. Users can choose the appropriate model and configuration according to specific needs.

In short, Baichy PYB series cone crusher is a crushing equipment with superior performance, reliability, and stability, which can meet various crushing needs and bring users an efficient, energy-saving, and environmentally friendly production experience.