In industries such as thermal power generation and coal chemical industry, fly ash is one of the main solid wastes. Traditional treatment methods mainly involve stockpiling or utilization as low-cost building materials, which not only occupies land but also poses environmental risks.

However, the unburned carbon and high-value cenospheres and microspheres abundant in fly ash are actually valuable resources.

The emergence of fly ash flotation systems provides a perfect technical solution for the recycling and utilization of these resources.

I. What is a Fly Ash Flotation System?

A fly ash flotation system is a specialized process line developed based on the principle of mineral flotation. Its core purpose is to efficiently separate the unburned carbon particles (usually the portion with a high loss on ignition) from the useful glass microspheres (cenospheres, sedimentary beads).

Simply put, this process is like "floatation": through physicochemical methods, useful substances "float" to the top, while useless or another useful substance "sinks," thereby achieving precise separation and enrichment.

II. Working Principle and Core Process of a Fly Ash Flotation System

The flotation process mainly relies on the differences in the physicochemical properties of the particle surfaces. Carbon particles have naturally hydrophobic surfaces, while glass microspheres are hydrophilic. Flotation systems utilize this key difference.

A complete fly ash flotation system typically includes the following four core components:

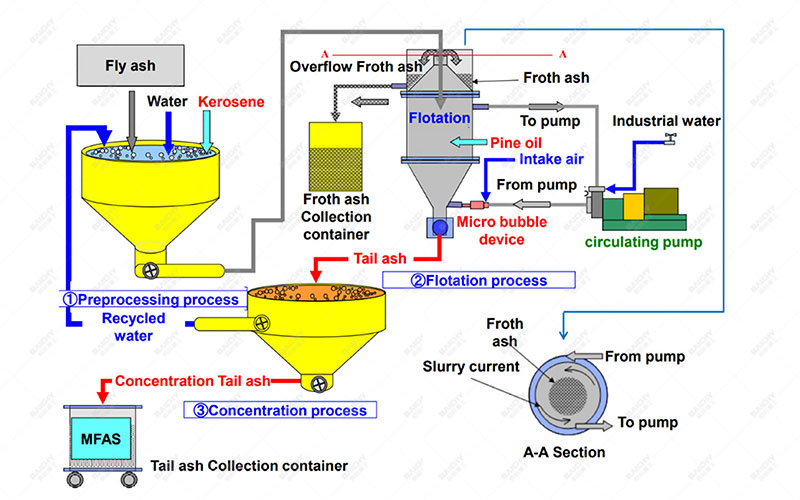

1. Pulping and Blending

◦ Purpose: To thoroughly mix dry fly ash and water in a mixing tank to prepare a pulp of suitable concentration, creating the fluid conditions for subsequent flotation.

◦ Key: The stability of the pulp concentration directly affects the flotation effect.

2. Reagent Addition

◦ Purpose: To add specific flotation reagents to amplify the difference in hydrophobicity between the carbon and ash particle surfaces.

◦ Commonly Used Reagents: Collectors (such as diesel and kerosene) enhance the hydrophobicity of carbon particles; frothers help form a large number of stable and uniform bubbles in the pulp.

3. Aerated Flotation Separation

◦ Purpose: This is the "heart" of the entire system. The slurry is fed into a flotation machine, where mechanical agitation and air injection generate a large number of microbubbles.

◦ Separation Process: Hydrophobic carbon particles, treated with reagents, adhere to the bubbles and float to the surface, forming a foam layer (called "carbon concentrate"). Hydrophilic microspheres and other substances remain in the slurry (called "tailings"). Carbon and ash are separated by scraping the foam off with a scraper.

4. Product Dewatering

◦ Purpose: To dewater the carbon foam obtained from flotation and the decarbonized tailings separately for easier transportation and sale.

◦ Common Equipment: Carbon powder is typically dewatered using a vacuum filter, while decarbonized ash (tailings) is usually dewatered using a chamber filter press to form a dry cake.

III. The Immense Value of Fly Ash Flotation

Investing in a flotation system can bring multi-dimensional benefits to enterprises:

• Economic Benefits:

◦ Recovering Carbon Powder: The enriched carbon powder has a high calorific value and can be sold as a high-quality fuel or an additive in the rubber and plastics industries, with a value far exceeding that of raw ash.

◦ Improving Ash Quality: After decarbonization, the loss on ignition of fly ash is significantly reduced, and the quality is improved to Grade I or II ash standards, making it a high-quality admixture for high-performance concrete, significantly increasing its selling price.

◦ Enriching High-Value Components: During the decarbonization process, the less dense cenospheres are further enriched in the flotation machine and can be recovered separately. Cenospheres are lightweight, high-strength thermal insulation materials with extremely high economic value.

• Environmental and Social Benefits:

◦ Realizing Solid Waste Resource Utilization: Transforming solid waste into useful resources aligns with the development policies of a circular economy and "zero-waste cities."

◦ Reducing Stockpiling and Pollution: Fundamentally reducing the land occupation and dust and groundwater pollution risks associated with fly ash stockpiling.

Creating Green GDP: Opening up new profit growth points for enterprises and achieving a harmonious unity between environment and development.

The fly ash flotation system is not just a piece of equipment, but a green technology that transforms the linear economic cycle of "resource-product-waste" into a circular economic cycle of "resource-product-recycled resources." It accurately uncovers the hidden value in fly ash, opening up new profit channels for enterprises while fulfilling their environmental responsibilities. With continuous technological advancements and maturity, flotation technology will inevitably become an indispensable core tool in the comprehensive utilization of fly ash.

If you wish to conduct a resource assessment of your fly ash or learn about flotation system solutions, please contact us. We will provide you with professional technical consultation and services.