In the field of gold cyanide extraction, CIP (Carbon-In-Pulp) and CIL (Carbon-In-Leach) are the two mainstream processes. This article will delve into their principles and processes, providing key differences and selection suggestions to help you optimize your gold ore processing scheme and maximize recovery.

I. Basics: Cyanide Leaching of Gold

Regardless of whether the subsequent process is CIP or CIL, the first step is the samecyanide leaching.

• Principle: The crushed and ground gold ore (pulp) is mixed with a diluted cyanide solution (such as NaCN). With the introduction of oxygen, gold reacts with cyanide ions to form a soluble gold-cyanide complex that enters the solution.

◦ Chemical Reaction: 4Au + 8NaCN + O₂ + 2H₂O → 4Na[Au(CN)₂] + 4NaOH

• Purpose: To convert solid, non-recoverable fine-particle gold into an ionic state in solution, preparing for subsequent adsorption and recovery.

The leaching effect directly determines the upper limit of the final recovery rate; therefore, ensuring sufficient leaching time and appropriate chemical conditions is crucial.

II. Core Process Analysis: CIP vs. CIL

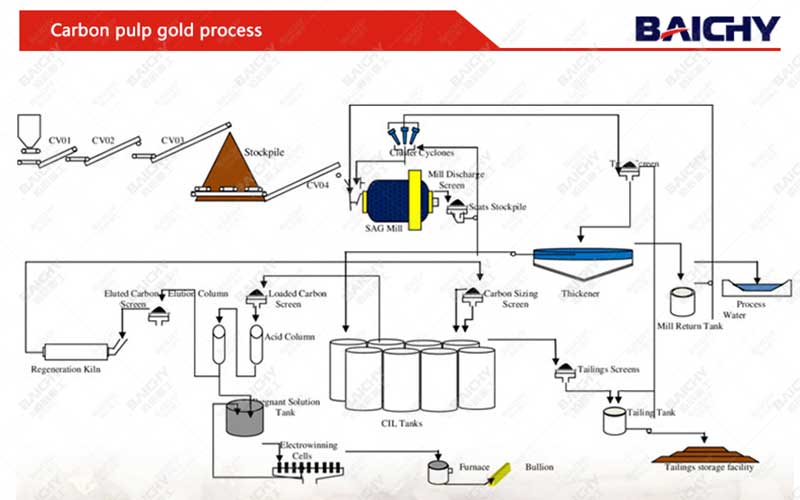

After leaching, the key is how to efficiently recover gold from the gold-bearing liquid (precious solution). CIP and CIL are activated carbon adsorption processes developed to solve this problem.

1. CIP Process (Carbon-In-Pulp)

Process: Leaching and adsorption are carried out separately and in series.

1. First Leaching: The slurry first passes through a series of leaching tanks in series, undergoing a sufficient cyanidation reaction to ensure maximum gold dissolution.

2. Second Adsorption: The leached slurry (now free of significant cyanide and oxygen) enters another series of adsorption tanks in series. The tanks are filled with activated carbon; as the slurry flows through, the gold-cyanide complexes in the solution are selectively adsorbed by the activated carbon.

• Features:

◦ Advantages: Leaching and adsorption conditions can be optimized separately without interference. Leaching tanks maintain high cyanide and oxygen concentrations, while adsorption tanks provide a gentler, more efficient environment for activated carbon.

◦ Suitable Scenarios: More suitable for processing ores with coarse gold particles, slow leaching rates, or complex mineral compositions.

2. CIL Process (Carbon-to-Injection)

Process: Leaching and adsorption occur simultaneously in the same series of tanks.

1. Simultaneous Processing: Cyanide, oxygen, and activated carbon are added to the same series of tanks.

2. Simultaneous Leaching and Adsorption: In the first half of the tank, the leaching reaction dominates; as the slurry flows further, the gold concentration in the solution increases, and the adsorption process gradually becomes dominant. Activated carbon is always present in the tank, adsorbing the newly dissolved gold in real time.

• Features:

◦ Advantages:

▪ Low Investment Costs: Reduces the need for separate leaching tank systems, resulting in lower investment in plant, equipment, and infrastructure.

▪ Shortened process cycle: Gold is immediately adsorbed upon dissolution, reducing the gold content in the solution and promoting the continuous positive leaching reaction, theoretically increasing the leaching rate.

▪ Reduced gold robbery: Gold is immediately captured by activated carbon after dissolution, reducing the risk of other minerals in the slurry (such as carbonaceous matter, talc, etc.) re-adsorbing or encapsulating gold (i.e., gold robbery).

◦ Applicable scenarios: This is currently the most popular and widely used process, especially suitable for gold ores containing gold robbery components or of general grade.

III. How to choose between CIP and CIL?

| Characteristics | CIP (Carbon-In-Pulp) | CIL (Carbon-Leach-In) |

| Process flow | Leach first, then adsorb. Clear process, segmented operation. | Leaching and adsorption occur simultaneously. High process integration. |

| Equipment investment | Higher (requires two independent tank series). | Lower (only one tank series is needed, currently the mainstream and preferred choice). |

| Plant area | Larger. | Relatively small. |

| Process Control | Leaching and adsorption conditions can be optimized independently, allowing for more precise control. | Conditions need to be balanced in both aspects, making control relatively complex, but modern automated systems can handle this well. |

| Anti-Gold Robbery Capability | Relatively weak. Gold is completely dissolved in the solution during leaching, posing a risk of secondary adsorption by harmful minerals. | Strong. Activated carbon can adsorb gold instantly, effectively suppressing gold robbery. |

| Applicable Ores | Ores with high leaching difficulty and complex mineral composition. | Most gold ores, especially those containing gold robbery components. |

IV. Conclusions and Selection Recommendations

• CIL process is the current standard for gold mine processing: Due to its comprehensive advantages such as low investment, small footprint, and effective overcoming of gold robbery problems, CIL is usually the preferred option in the design of new concentrators.

• CIP process still has value in specific scenarios: When the ore properties are particularly complex, requiring very precise control of leaching and adsorption parameters to achieve optimal recovery, the independent control advantage of the CIP process becomes apparent. Furthermore, CIP (Continuous Infiltration) is often used to increase adsorption capacity when upgrading existing leaching plants.

The final decision-making process: Choosing between CIP and CIL is not a simple matter of judging superiority or inferiority; it must be based on detailed mineralogical studies of the ore process, a thorough feasibility study, and an economic benefit assessment. It is recommended to collaborate with a professional mineral processing design institute to determine the best gold extraction solution for your mine through experimental data.

Hopefully, this detailed blog post meets your requirements!