The core principle of gold gravity beneficiation is to utilize the difference in specific gravity between gold and other gangue minerals, separating them under the action of a fluid (usually water). The entire process follows the principle of early recovery and maximum recovery, aiming to recover the liberated free gold as soon as possible after ore grinding to prevent over-grinding or loss.

An efficient process typically includes the following stages:

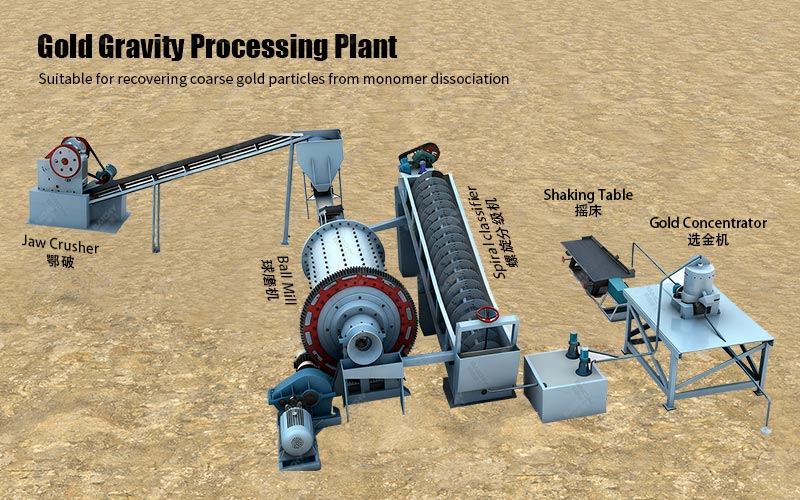

Stage 1: Pretreatment (Crushing and Grinding)

This is the foundation of any beneficiation process. The goal is to crush and grind the raw ore to a particle size sufficient to liberate gold particles from the gangue.

• Crushing: Using jaw crushers, cone crushers, etc., large pieces of raw ore are crushed into smaller pieces (usually less than 25mm).

• Grinding: Using ball mills or rod mills, the smaller pieces of ore are further ground into fine powder. The key is to control the grinding fineness: if ground too coarsely, the gold particles will not be liberated, resulting in low recovery; if ground too finely, the gold particles are easily over-ground and muddy, making recovery equally difficult.

Stage Two: Classification

The ground slurry enters classification equipment (such as hydrocyclones or spiral classifiers). Its function is to separate the slurry according to particle size:

• Qualified particles: Fine-grained products enter the next classification process.

• Unqualified particles: Coarse-grained products are returned to the mill for regrinding, forming a closed-loop cycle to ensure uniform particle size of the ground products.

Stage Three: Core Gravity Separation (Multi-stage Recovery)

This is the heart of the process. To maximize recovery, modern gravity concentrators typically employ a combined process of roughing, scavenging, and cleaning, using different equipment to leverage their respective advantages.

1. Roughing:

◦ Objective: To quickly and in large quantities recover liberated coarse and medium-grained gold.

◦ Commonly Used Equipment: Jigs.

◦ Location: Usually placed at an appropriate location in the grinding-classification loop (such as at the return sand point of the classifier), with the aim of recovering as soon as possible.

2. Scavenging:

◦ Objective: To recover fine gold particles that are difficult to process from the roughing tailings. This is key to improving the overall recovery rate, especially for dealing with flaky gold and fine-grained gold.

◦ Common Equipment: Centrifugal concentrators, such as Nelson and Falcon concentrators. They greatly enhance the separating force by generating a strong centrifugal force field, recovering particles down to 10-20 micrometers.

◦ Location: Processing tailings from roughing equipment such as jigs.

3. Cleaning:

◦ Objective: To enrich and purify the rough concentrate obtained from roughing and scavenging to obtain a high-grade final gold concentrate for direct smelting.

◦ Common Equipment: Shaking tables. They can accurately separate minerals by specific gravity, producing high-grade gold concentrate, middlings, and tailings. Middlings are usually returned to the process for further processing.

Phase Four: Product Processing

• Gravity Concentrate: Gold concentrate obtained from shaking tables and other concentrators, if of sufficiently high grade, can be directly smelted. Sometimes, amalgamation (under safe and environmentally friendly conditions) or a combined gravity-flotation process is used for further processing.

• Tailings: Tailings from gravity concentration usually contain gold that can only be recovered using chelates or chemical methods. These are then fed into subsequent flotation or cyanide leaching systems for secondary recovery. The final, unusable tailings are discharged into a tailings pond.

Process Characteristics and Advantages

• High Efficiency and Energy Saving: Gravity concentration primarily utilizes the density difference of minerals and the force of water, resulting in low power consumption, no need for chemical reagents, and low cost.

• Environmentally Friendly and Pollution-Free: No chemicals are added, and there is no toxic wastewater discharge.

• High Return on Investment: Low operating costs, early recovery of high-value free gold, and rapid cash flow generation.

• High flexibility: It can be used as a standalone process for placer gold or simple vein gold, or as a pre-selection operation before flotation and cyanidation, reducing the load on subsequent processes and improving the overall plant recovery rate.

We hope this detailed process flow description will help you fully understand the core operating mechanism of a gold gravity concentrator. If you have specific types of gold ore to discuss, we can further analyze their customized process solutions.