PF1007 Impact Crusher

In the field of mining crushing, equipment models often represent their capabilities and positioning. The PF1007 impact crusher, a classic model in the impact crusher series, has a model name that itself contains key information: PF stands for impact crusher, and 1007 refers to a rotor diameter × length of Φ1000 × 700mm. Since its introduction, this equipment has become one of the preferred choices for medium-fine crushing of medium-hardness, low-abrasion materials (such as limestone, coal gangue, concrete, etc.) due to its reasonable structure, efficient crushing capacity, and wide applicability. As a mining crushing equipment manufacturer with 20 years of experience, we understand that behind a long-lasting piece of equipment lies the market's long-term verification of its performance and reliability.

Product Overview: Core Parameters and Working Principle

The PF1007 impact crusher utilizes a high-speed rotating rotor to drive the hammer plates to impact the material, causing the material to be repeatedly thrown and impacted against the impact plates in the crushing chamber, thus achieving a composite crushing effect of stone-on-stone and stone-on-metal. This principle results in finished product particles that are mostly cubic in shape and uniform in size, making it particularly suitable for use as construction aggregate.

Core Parameters Overview:

| Key Words | Medium and Fine Crushing Equipment |

|---|---|

| Product Model | Impact Crusher |

| Feed Size | 400×730mm |

| Motor Power | 37-45 kW |

| Capacity | 30-70 t/h |

| Core Advantages | High efficiency and energy saving, excellent particle shape, flexible adjustment, and simultaneous shaping capabilities. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Core Advantages: The Accumulation of 20 Years of Manufacturing Experience

Based on our twenty years of R&D and manufacturing experience, the PF1007 impact crusher we provide has undergone several optimizations based on the classic design, possessing significant advantages:

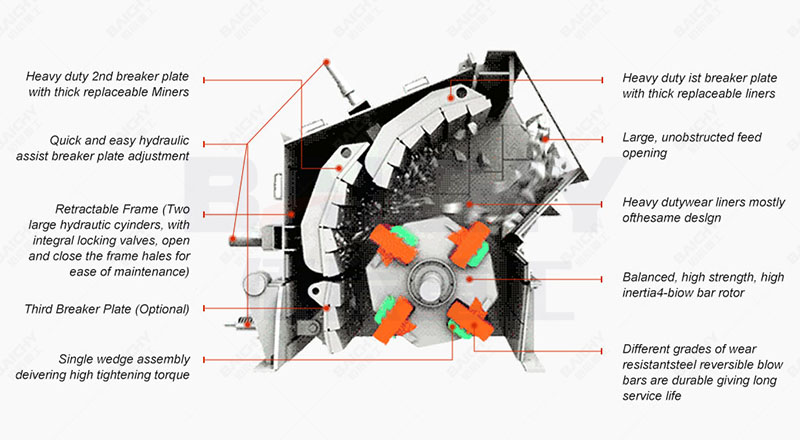

PF Impact Crusher Structure Diagram

1. High-chromium hammer plates, wear-resistant and impact-resistant: Using new high-chromium alloy hammer plates, the wear resistance and impact toughness are significantly improved, extending the service life by more than 30%, effectively reducing operating costs.

2. Hydraulic Opening, Convenient Maintenance: The machine casing features a hydraulic opening device, allowing for easy operation by a single person, greatly facilitating the inspection and replacement of internal components such as the rotor and impact plates, thus shortening downtime.

3. Excellent Product Particle Shape: The unique impact plate design and optimized crushing chamber ensure sufficient impact and collision of materials, resulting in a three-dimensional particle shape, reasonable gradation, and controllable fines content, meeting high-standard aggregate requirements.

4. Robust Structure, Stable Operation: The heavy-duty rotor design provides a large moment of inertia, stronger crushing force, and more stable operation. Key components are optimized using finite element analysis technology, resulting in extremely high equipment reliability.

5. Strong Versatility, Multi-purpose Machine: By flexibly adjusting the gap between the impact frame and the rotor, the output particle size can be effectively controlled, meeting the perse particle size requirements of different users.

PF impact crusher crushing site

Application Cases: Performance Verified in Practice

Case Study 1: A Limestone Crushing Production Line in East China

The customer used the PF1007 as a secondary crushing equipment to crush limestone with a particle size of ≤250mm. The production line has been running stably for over 3 years, with a stable output of 55-60 tons per hour. The finished aggregate has a needle-like and flaky content of less than 8%, fully meeting the high standards of local commercial concrete plants. The customer particularly praised the durability of the impact plates, with one set of impact plates handling approximately 80,000 tons of material.

Case Study 2: A Construction Waste Recycling Project in Central China

In this project, the PF1007 impact crusher was responsible for crushing the pre-sorted concrete blocks. Its unique crushing method effectively separated the rebar from the concrete, resulting in high-quality recycled aggregate. It became one of the core pieces of equipment in the project, demonstrating its adaptability in handling complex materials.

Stone crushing plant

Related Equipment Recommendation: Building an Efficient Production Line

A single PF1007 usually does not work alone; it needs to cooperate with upstream and downstream equipment to form an efficient production line. As a complete solution provider, we recommend the following supporting equipment:

- Upstream Feeding: ZSW380×96 vibrating feeder, providing uniform and stable feeding to maximize its efficiency. - Upstream Primary Crushing: PE400×600 jaw crusher performs the first stage of primary crushing, preparing suitable feed material for the PF1007.

- Downstream Screening: 3YK1237 circular vibrating screen classifies the crushed material, producing finished products of various specifications.

Frequently Asked Questions (FAQ)

Q1: What are the maximum feed and discharge particle sizes of the PF1007?

A1: The maximum allowable feed size is generally 300mm. The discharge particle size can be controlled by adjusting the gap of the impact plate, usually adjustable within the range of 0-40mm, with common main product particle sizes around 20-30mm.

Q2: What is the replacement cycle of the hammer plates? What is their service life?

A2: This depends on the hardness and abrasiveness of the material being crushed. For medium-hard limestone, the high-chromium hammer plates we use typically have a service life of 300-600 hours. We offer hammer plates with a quick-change design, significantly reducing replacement time.

Q3: Is this equipment suitable for crushing granite?

A3: The PF1007 can handle materials with low to medium abrasiveness. While it can crush high-hardness granite, the wear of the hammer plates and impact plates will be significantly accelerated, resulting in higher operating costs. For projects involving long-term granite crushing, we recommend a cone crusher.

Q4: Do you provide installation guidance and technical support?

A4: Absolutely. We provide detailed foundation drawings, installation manuals, and can dispatch experienced engineers for on-site installation guidance, commissioning, and operation training to ensure the equipment is quickly put into optimal operation. We have 20 years of global service experience.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.