Limestone grinding production line complete equipment

One-stop solution from coarse crushing to 325 mesh fine powder processing

1. Industry pain points: key challenges in limestone powder processing

Limestone (calcium carbonate) is widely used in building materials, chemical industry, metallurgy and other fields, but traditional processing methods often face:

✘ Low coarse crushing efficiency: Improper selection of jaw crusher leads to mismatched production capacity

✘ Substandard fineness: Ordinary Raymond mill is difficult to produce fine powder above 325 mesh (45μm) stably

✘ High dust pollution: Open design does not meet environmental protection requirements

✘ High energy consumption cost: Unreasonable equipment combination leads to electricity bills accounting for more than 30%

Solution: Modular design production line, covering the entire process of coarse crushing → medium crushing → grinding → grading → packaging, precise control of fineness (80-325 mesh adjustable), and energy consumption reduced by 40%

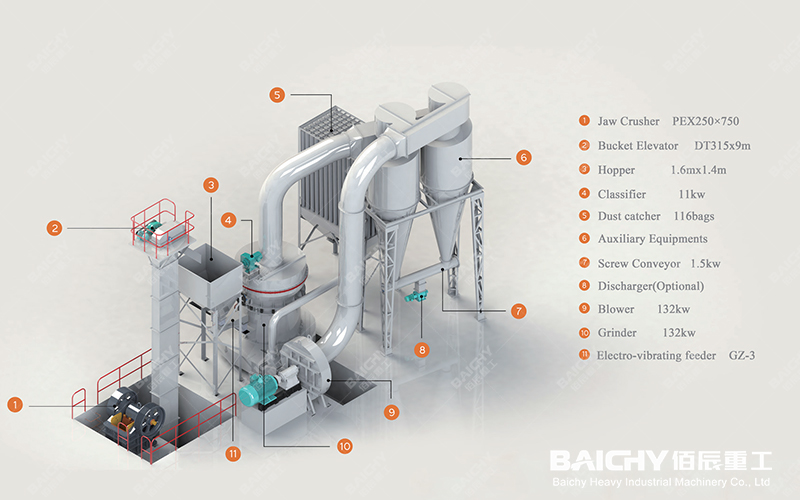

2. Analysis of the core equipment of limestone grinding production line

① Coarse crushing stage: jaw crusher

Function: crush the raw ore (≤800mm) to ≤50mm

Recommended model: PE600×900(50-100 t/h)

Advantages: high manganese steel jaw plate is wear-resistant, hydraulic adjustment of discharge port

② Medium and fine crushing stage: impact crusher/cone crusher

Applicable scenarios:

Impact crusher (processing hardness ≤350MPa, good finished product particle shape)

Cone crusher (high hardness ore, more than 200 tons per hour)

③ Grinding core: Raymond mill/vertical mill

| Equipment type | Fineness range | Capacity (T/H) | Applicable scenarios |

| Raymond mill | 80-325 mesh | 1-20 | Small and medium scale, low investment |

| Vertical mil | 325-2500 mesh | 5-50 | Large project, high fineness |

3. Production line process (with flow chart)

Coarse crushing → 2. Screening (vibrating screen) → 3. Medium crushing → 4. Grinding (with analyzer) → 5. Powder collection (cyclone + bag dust collector) → 6. Packaging

Case data:Guangxi calcium carbonate plant: equipped with PE600×900 jaw crusher + HST160 cone crusher + LM1900 vertical mill, with an annual output of 325 mesh limestone powder of 300,000 tons and power consumption of only 18kWh/ton.

4. Why choose our production line?

✔ Customized design: Match equipment according to raw material hardness, production capacity (1-100T/H), and fineness requirements

✔ Energy-saving certification: 15% lower energy consumption than national standards (with test report)

✔ After-sales guarantee: 24-hour response, lifelong maintenance of key components

5. FAQ

Q1: What are the uses of 325 mesh limestone powder?

Plastic filling (800-1250 mesh), coating (325-600 mesh), desulfurizer (200-325 mesh)

Q2: How much does it cost to invest in a production line with an output of 10 tons per hour?

Basic configuration (jaw crusher + Raymond mill) is about 800,000-1.2 million, click to get a detailed quotation