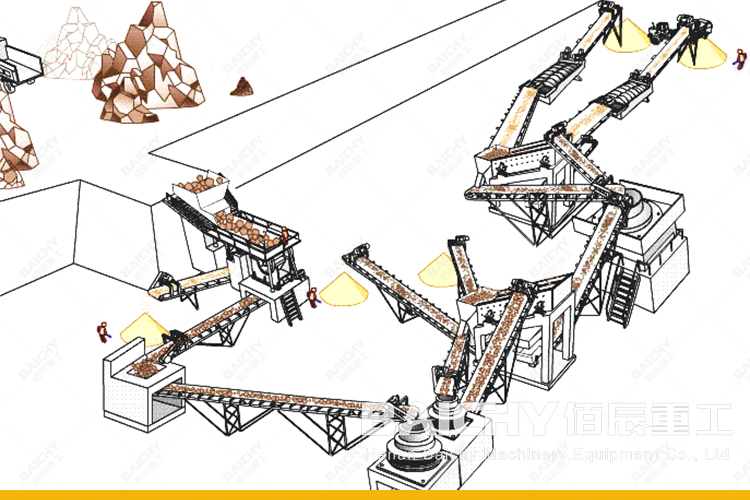

Systematic analysis of the work process of the stone crushing station: the whole process of efficient crushing process

1. Raw material pretreatment system

• Raw material transportation: adopt truck/conveyor belt dual mode transportation to ensure continuous supply of raw materials

• Pre-screening treatment: equipped with multi-stage vibrating screen to effectively remove impurities and dust (dust removal efficiency ≥95%)

2. Three-stage crushing process system

Primary crushing section

• Equipment selection: jaw crusher (feed particle size ≤1500mm) or impact crusher

• Crushing principle: adopt movable jaw-fixed jaw extrusion crushing technology, the crushing ratio can reach 6-8

Intermediate crushing section

• Core equipment: hydraulic cone crusher (equipped with automatic adjustment device)

• Technical features: laminated crushing principle, excellent finished product particle shape, needle-like content <10%

Closed-loop circulation system

• Intelligent feedback mechanism: excessive materials automatically return for re-crushing

• Circulation efficiency: processing capacity can reach 800-1200 tons per hour

3. Intelligent screening system

Multi-stage vibration screening

• Grading accuracy: 4-6 specifications of finished materials can be produced at the same time

• Screening efficiency: >98% qualified rate guaranteed

Finished product classification system

• Specification control: 0-5mm/5-10mm/10-20mm and other multi-grade matching

• Quality detection: real-time monitoring by online particle size analyzer

4. Environmental protection control system

• Dust removal system: pulse bag dust removal (dust concentration <20mg/m³)

• Noise reduction measures: modular sound insulation design (factory boundary noise <65dB)

• Water mist dust suppression: intelligent spray system in crushing area

5. Finished product storage and transportation system

• Automated stacking: radial stacker (stack height can reach 15 meters)

• Intelligent loading system: quantitative loading error <0.5%

• Transportation plan: support multi-mode shipment by road/rail/shipping

6. Technical advantages:

• Energy consumption index: power consumption per ton <3.5kWh

• Equipment utilization rate: effective operation time throughout the year ≥8000 hours

• Automation degree: PLC control system realizes full process monitoring6.

7. Application areas:

• Construction engineering: C30-C60 concrete aggregate

• Road construction: various levels of asphalt concrete batching

• Railway ballast: special/first-class ballast material

• Water conservancy project: filter material/cushion material

This crushing station adopts the "crushing-screening-re-crushing" closed-loop circulation process, and realizes precise control of particle size through intelligent control system. The qualified rate of finished products is stable at more than 99.2%, providing high-quality aggregate solutions for infrastructure construction.