Detailed Explanation of the Structure and Working Principle of Single-Rotor Impact Crushers

As a manufacturer with 20 years of experience in mining crushing equipment, we understand that choosing the right crushing equipment is crucial for the efficiency of the production line and the quality of the final product. Among the many types of crushers, the single-rotor impact crusher, with its unique structure and efficient working principle, occupies an important position in the medium and fine crushing of medium-hard materials. This article will provide a comprehensive analysis of all aspects of this equipment, drawing on our years of industry experience.

| Key Words | Single-Rotor Impact Crushers |

|---|---|

| Product Model | Impact Crusher |

| Feed Size | ≤400mm |

| Motor Power | 45-315kw |

| Capacity | 10-400 t/h |

| Core Advantages | High efficiency and energy saving, excellent particle shape, flexible adjustment, and simultaneous shaping capabilities. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why is the single-rotor impact crusher so popular?

In industries such as sand and gravel aggregates, mining, metallurgy, and building materials, material crushing requires not only efficiency but also excellent particle shape. Compared to equipment that relies primarily on compression, such as jaw crushers and cone crushers, the single-rotor impact crusher utilizes the stone-on-meta and stone-on-ston principles to produce finished materials with excellent cubic particle shape and low needle-like and flaky content, making it ideal for sand making and shaping. Understanding its internal mechanism is key to optimizing production line configuration.

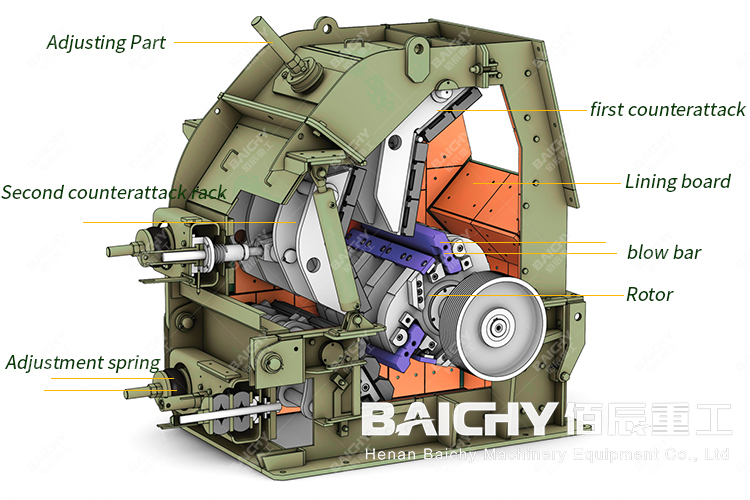

Single-Rotor-Impact-crusher-structure

Structural Overview: A Combination of Robustness and Precision

A typical single-rotor impact crusher mainly consists of the following core components:

• Rotor assembly: The heart of the equipment. It consists of a heavy-duty main shaft, multiple discs, and hammers (impact plates) mounted on the discs. The rotor rotates at high speed driven by a high-speed motor, which is the source of kinetic energy.

• Impact plate: Also known as the counter-attack plate or liner plate, it is fixed to the inside of the frame and forms a crushing chamber with the rotor. Its angle and distance can be adjusted to control the output particle size.

• Machine body frame: Made of heavy-duty steel structure welding, ensuring the stability and durability of the equipment under high-speed impact loads.

• Feed hopper and guide plate: Ensure that the material is evenly and accurately fed into the central area of the rotor for efficient crushing.

• Drive system: Usually composed of a motor and belt drive device (or direct connection), providing power.

• Maintenance lifting device: Advanced designs will be equipped with a hydraulic opening device to facilitate quick inspection and replacement of internal wear parts (such as hammers and impact plates), greatly reducing downtime. Working Principle: A Paradigm of Kinetic Energy Crushing

The single-rotor impact crusher operates on the principle of kinetic energy impact crushing, with the following specific process:

1. Acceleration and Impact: Material falls from the feed opening into the center of the high-speed rotating rotor, where it is violently struck by the hammer plates and accelerated to extremely high speeds, then projected outwards.

2. Secondary Impact and Crushing: The projected material first impacts the adjustable impact plate above, undergoing a violent initial impact crushing stone-on-meta ).

3. Repeated Collisions and Shaping: The crushed material rebounds back into the rotor area, colliding at high speed with the subsequent stream of projected material stone-on-ston ), achieving further crushing and shaping.

4. Grading and Discharge: After multiple impacts and collisions within the crushing chamber, material of the desired particle size is discharged from the discharge opening at the bottom of the machine. Particle size is controlled by adjusting parameters such as rotor speed and impact plate gap.

Core Advantages and Features

After 20 years of technological iteration and field verification, modern single-rotor impact crushers demonstrate the following irreplaceable advantages:

• Excellent Particle Shape: The finished particles are mostly cubic in shape, with a reasonable gradation and extremely low content of needle-shaped and flaky particles, making them ideal for high-quality concrete aggregate and manufactured sand.

• High Efficiency and Energy Saving: Large crushing ratio, with a single machine achieving a crushing ratio of up to 40-50, simplifying the process flow. Energy is directly applied to the material, resulting in high efficiency.

• Flexible Adjustment: Rotor speed and impact plate gap can be easily adjusted hydraulically or mechanically, enabling quick and flexible control of the output particle size, allowing for multi-purpose use of the machine.

• Relatively Simple Maintenance: The main wear parts, such as hammer plates and impact plates, adopt a modular design, and the machine frame can be quickly opened using a hydraulic device, significantly reducing maintenance labor intensity and time.

• Sand Making Function: Through optimized parameters and cavity design, it can be specifically used to produce high-quality manufactured sand, making it one of the core equipment in current sand and aggregate production lines.

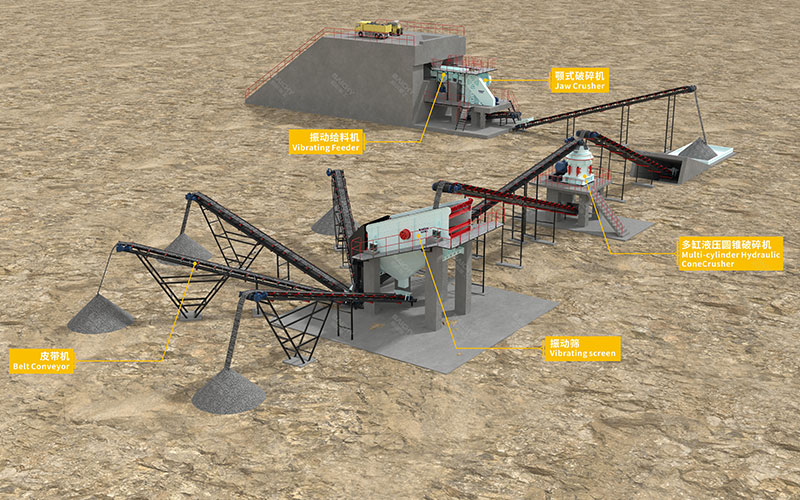

Impact crushing production line

Application Case: Feedback from Our Customer Site

We provided HX series single-rotor impact crushers to a large green building materials industrial park in East China for limestone shaping and sand making. This equipment replaces the original two-stage crushing scheme, with a single unit completing the shaping task from 40mm feed to producing 0-5mm high-quality manufactured sand. The finished sand particles are round and smooth, with adjustable fineness modulus, fully meeting the national Class II medium sand standard. Customer feedback indicates an overall efficiency improvement of more than 30%.

Related Equipment Recommendations

• Coarse Crushing Partner: Jaw Crusher. As the pionee of the production line, its stable performance is the basis for ensuring efficient feeding of the single-rotor impact crusher.

• Front-end Partner: Cone Crusher. For highly abrasive materials (such as granite and basalt), the cone crusher + impact crushe scheme is recommended. The cone crusher is responsible for medium crushing, and the impact crusher is responsible for fine crushing and shaping, balancing wear cost and particle shape.

• Back-end Partner: Vibrating Screen. Forms a closed-loop circulation system to ensure that the final product particle size meets the precise standards.

Frequently Asked Questions (FAQ)

Q1: What is the difference between single-rotor and double-rotor impact crushers?

A1: The single-rotor structure is relatively simple, focusing on medium and fine crushing and shaping, with flexible adjustment. Double-rotor crushers usually have two rotors in series, with a larger crushing ratio, and can be used for single-stage crushing, but the structure is more complex, and the power consumption and cost are higher. The choice depends on the specific process requirements.

Q2: What is the service life of wear parts such as the hammer plates?

A2: This depends on the abrasiveness of the crushed material (e.g., the significant difference between granite and limestone), the feed particle size, and the equipment operating parameters. Generally, when crushing moderately abrasive materials, a set of high-quality hammer plates can last from several hundred to thousands of hours. We offer hammer plates made of various alloy materials for customers to choose from.

Q3: Is this equipment suitable for processing wet and sticky materials?

A3: No. Impact crushers mainly rely on high-speed impact. Wet and sticky materials easily adhere to the inside of the crushing chamber, rotor, and impact plates, leading to blockage and a sharp decrease in efficiency, or even equipment damage. For wet and sticky materials, equipment such as roller crushers should be considered.

Q4: How to minimize the operating and maintenance costs of the equipment?

A4: There are three key points: firstly, ensuring uniform and continuous full feedin of the material; secondly, regularly inspecting and replacing wear parts on time to prevent excessive wear from damaging other components; and thirdly, using original or reliable compatible wear parts to ensure proper fit.