The importance of industrial grinding equipment

In mining, metallurgy, building materials, chemical industry and other industries, material crushing and grinding are key links in the production process. Choosing the right grinding equipment directly affects production efficiency, energy consumption cost and product quality. Powerful grinder and ball mill are two mainstream industrial grinding equipment, but they have significant differences in structure, working principle and application scenarios. This article will compare the characteristics of the two in detail to help you make the best choice.

1. Powerful grinding machine vs. ball mill: core difference

Working principle comparison

| Equipment type | Working principle | Applicable materials | Grinding fineness | Energy consumption characteristics |

| Powerful grinding machine | High-speed rotating hammer or blade impacts and crushes the material | Medium hardness, brittle materials (such as limestone, coal, gypsum) | Medium fine crushing (0.1-5mm) | Low energy consumption, suitable for continuous production |

| Ball mill | Use steel balls or ceramic balls to roll and rub in the drum to achieve fine grinding | High hardness ores (such as iron ore, gold ore, quartz) | Ultrafine powder (<0.1mm) | High energy consumption, suitable for high-precision grinding |

2. Structural differences

Powerful grinding machine:

Using high-strength wear-resistant materials (such as high-chromium alloy linings)

Equipped with intelligent frequency conversion control system, adjustable speed

Suitable for dry or wet grinding (customized anti-rust design required)

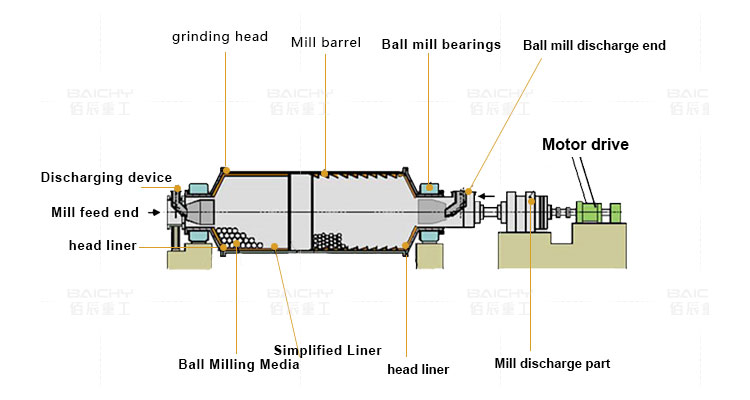

Ball mill:

The cylinder is lined with wear-resistant materials (rubber, manganese steel, etc.)

Control fineness by adjusting the size of steel balls and filling rate

Suitable for ultra-fine powder processing, but the maintenance cost is high

How to choose the right grinding equipment?

1. Key selection factors

✔ Material properties (hardness, moisture content, particle size requirements)

✔ Capacity requirements (hourly processing volume, such as 1-100 tons)

✔ Energy consumption and maintenance costs (ball mills have higher power consumption, but better fineness)

✔ Wear resistance (powerful grinding mills have longer lining life)

2. Recommended selection options

Coarse crushing + medium and fine crushing → powerful grinding mill (such as GM-500, processing volume 10t/h)

Ultrafine powder processing → ball mill (such as QM-800, fineness up to 400 mesh)

High hardness materials → ball mill + grinding aid system (improve grinding efficiency)

3. Powerful grinding mill vs ball mill: industry application cases

1. Mining industry

Powerful grinding machine: used for limestone pre-crushing, production capacity increased by 30%

Ball mill: used for ultra-fine grinding of gold ore, recovery rate increased to 92%

2. Building materials industry

Powerful grinding machine: cement raw material crushing, energy consumption reduced by 25%

Ball mill: slag micro-powder preparation, fineness up to 600 mesh

3. Chemical industry

Powerful grinding machine: coal crushing, suitable for high-humidity materials

Ball mill: ultra-fine grinding of pigments, more uniform particle size distribution

4. Frequently Asked Questions (FAQ)

Q: Can a powerful grinding machine replace a ball mill?

A: It depends on the hardness and fineness requirements of the material. A powerful grinding machine is suitable for medium and fine crushing, and a ball mill is more suitable for ultra-fine powder processing.

Q: What should I do if the ball mill steel ball loss is large?

A: Use high-manganese steel balls and regularly replenish the grinding media (it is recommended to check every 3 months).

Q: Equipment price and delivery time?

A: Powerful grinding machine (50,000-300,000), ball mill (100,000-500,000), delivery time 15-30 days (customization is supported).

How to make the best choice?

• Powerful grinding machine: suitable for medium hardness materials and medium and fine crushing requirements, low energy consumption and simple maintenance.

• Ball mill: suitable for high hardness ores and ultra-fine powder processing, with higher fineness but higher energy consumption.