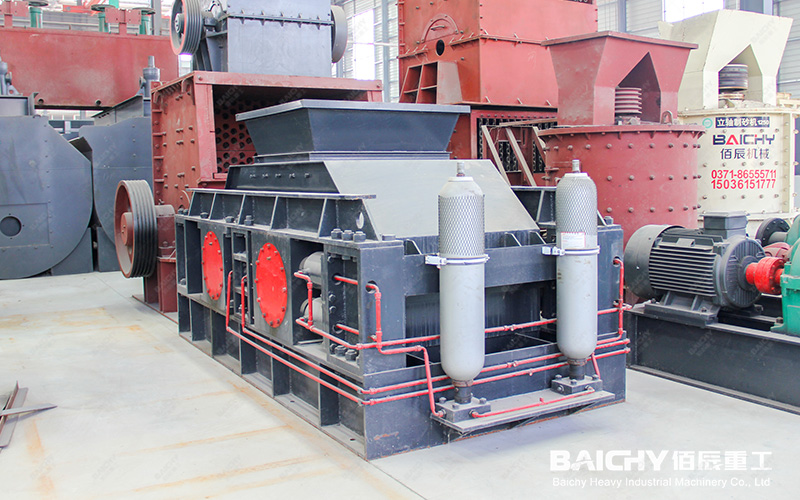

Double Roll Crusher Manufacturers and Suppliers

In the field of medium and fine crushing of ores and materials with medium hardness or less in industries such as mining, building materials, and chemicals, double-roll crushers have consistently held an irreplaceable position due to their simple structure, low over-crushing rate, and uniform product particle size. However, the market is flooded with numerous double-roll crusher manufacturers and suppliers, resulting in varying equipment quality and service levels.

Choosing a reliable and professional partner is crucial to ensuring production continuity and economic efficiency. This article will delve into the core value of double-roll crushers and explain why a manufacturer with 20 years of extensive experience is your preferred choice.

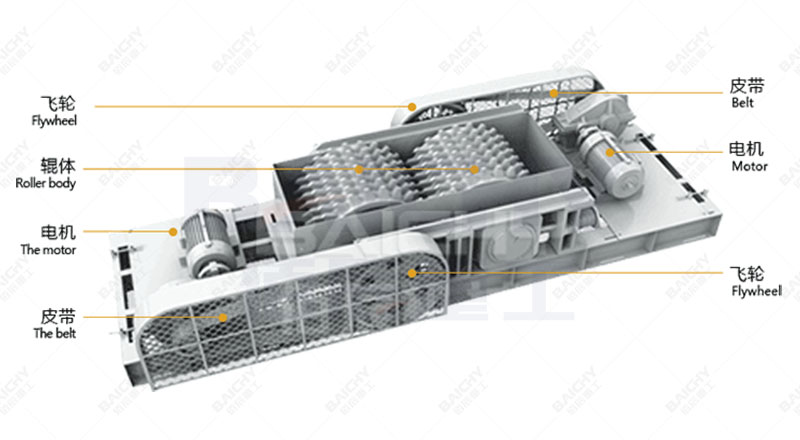

Structure diagram of a double-roll crusher

Why is the professionalism of a double-roll crusher manufacturer so important?

The working principle of a double-roll crusher seems simple – crushing materials through compression and shearing by two counter-rotating rollers. However, the underlying manufacturing process, material selection, assembly precision, and power configuration all profoundly affect the equipment's ultimate performance, service life, and maintenance costs. A seasoned double-roll crusher manufacturer, with its rich engineering experience, can excel in the following aspects:

1. Precise roller shell design and material matching: Selecting high-manganese steel, wear-resistant alloys, or other special steels based on different material characteristics (abrasiveness, humidity, hardness), and designing scientific tooth shapes or patterns to achieve the best balance between crushing efficiency and wear resistance.

2. Stable and reliable frame and bearing housing: Ensuring that the equipment structure remains stable and the bearings operate smoothly under long-term high-load impact, reducing vibration and downtime.

3. Flexible adjustment and overload protection mechanisms: Mature discharge particle size adjustment devices and spring or hydraulic protection systems effectively prevent catastrophic damage to the equipment caused by uncrushable objects such as iron blocks.

Therefore, choosing a double-roll crusher supplier with a long history of technological expertise is far more than just purchasing a piece of equipment; it's about acquiring a time-tested and reliable productivity solution.

Twenty Years of Dedication, Specialization Creates Professionalism

We are a seasoned manufacturing enterprise that has been dedicated to the field of mining crushing equipment for twenty years. Since our establishment, we have consistently prioritized technological research and development and process innovation, focusing on the in-depth optimization and manufacturing of core products such as double-roll crushers. Our factory is equipped with advanced production lines and testing equipment, implementing full-process quality control from material cutting, welding, and heat treatment to precision machining and assembly. Over the past twenty years, we have served customers in dozens of countries and regions worldwide, with applications covering a variety of materials including coal, coke, limestone, slag, and clay. This has allowed us to accumulate an unparalleled database of practical experience and application knowledge. We are not only a manufacturer of equipment, but also a problem solver for crushing processes.

Our Core Advantage: Beyond Manufacturing, Focused on Value Creation

Choosing us as your double-roll crusher manufacturer and supplier will provide you with the following unparalleled advantages:

Deep Technical Expertise: Twenty years of dedication have given us a thorough understanding of every detail of double-roll crushers. We can provide the most cost-effective customized solutions based on your specific material samples and production requirements.

Exceptional Product Durability: We adhere to the principle of high-quality materials and exquisite craftsmanship. The roller body uses integral forging or high-strength castings, and the roller shell uses special wear-resistant materials, ensuring that the core crushing components have a lifespan extended by more than 30%, significantly reducing your cost per ton of material processed.

Intelligent Structural Design: Modular design makes maintenance (such as roller shell replacement) simpler and faster; a flexible spring pressure or hydraulic adjustment system allows you to adjust the product particle size in minutes, making production switching more flexible.

Full Lifecycle Service Support: From on-site surveys, solution design, installation guidance, commissioning and operation to operator training and spare parts supply, we provide a one-stop service throughout the entire lifecycle of the equipment. Our expert team is your strong support.

Double-roll crusher customer site

Successful Case Studies

Case Study 1: Large-scale Coal Washing Project in South Africa

◦ Challenge: The customer needed to crush raw coal to -30mm, requiring a low over-crushing rate and minimal fines production to improve washing efficiency and coke quality.

◦ Solution: We recommended a large-scale powerful double-roll crusher with a deep-toothed roller shell design to enhance gripping and shearing force. It was also equipped with a hydraulic gap adjustment system. Results: The equipment operates stably, and the product particle size is uniform and controllable, fully meeting the requirements for washing and sorting. The over-crushing rate is reduced by approximately 15% compared to the customer's original equipment, earning high praise from the customer.

Case Study Two: Overseas Mexico Limestone Grinding Production Line

Challenge: The old equipment in the pre-crushing stage of the production line had a high failure rate and required frequent maintenance, seriously affecting the continuous and stable feeding of the downstream grinding system.

Solution: We replaced the old equipment with a heavy-duty double-roll crusher. We optimized the wear-resistant layer of the roller surface and strengthened the sealing and dustproof design of the bearing housing, specifically for the characteristics of limestone.

Results: Since the new equipment was put into operation two years ago, there have been no unplanned shutdowns except for regular replacement of wear parts, ensuring the continuous and efficient operation of the entire production line, and significantly improving the customer's overall efficiency.

Related Product Recommendations

In addition to our core double-roll crushers, as a comprehensive manufacturer of mining crushing equipment, we can also provide you with complete crushing and screening system solutions:

| Jaw Crusher | Used for primary coarse crushing in the production line, providing ideal feed for the subsequent double-roll crusher. |

| Vibrating Feeder and Vibrating Screen | Achieve uniform feeding and screening of qualified products, forming an efficient closed loop. |

| Conveying Equipment | Connects various process stages to ensure smooth material transfer. |

Frequently Asked Questions (FAQ)

Q1: What materials can your double-roll crusher mainly process?

A1: Our equipment is widely applicable to materials with a compressive strength below 160MPa, such as coal, coke, limestone, slag, clay shale, gypsum, etc., and is particularly suitable for materials that require reduced over-crushing.

Q2: What is the lifespan of the key wear parts (such as roller shells)? What is the delivery time?

A2: Depending on the abrasiveness of the material, the lifespan of the roller shells is usually 6-18 months. We maintain a stock of standard wear parts and can pre-produce based on forecasts to ensure that spare parts are delivered to the customer's site in the shortest possible time (usually 7-15 days), minimizing downtime.

Q3: Do you support customization according to our special requirements?

A3: Yes, absolutely. Customization is one of our core capabilities. We can adaptively design and manufacture equipment based on your specific feed particle size, output requirements, production capacity, and site space limitations, adjusting dimensions, power, and structure accordingly.

Q4: How do you guarantee installation and after-sales service for overseas projects?

A4: For overseas projects, we provide detailed English installation drawings and video guides, and can provide remote debugging guidance via online video. We have established a network of agents in multiple regions and can quickly dispatch engineers to the site to resolve complex issues. We also provide comprehensive operation and maintenance manuals.

In an increasingly competitive market environment, choosing reliable equipment and a trustworthy partner is the first step towards reducing costs and increasing efficiency. For twenty years, we have focused on one thing: creating more durable, efficient, and intelligent mining crushing equipment. If you are looking for an experienced double-roll crusher manufacturer and supplier, we look forward to discussing your needs in detail and using our expertise to contribute to your success.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.