In high-tech industries such as fine chemicals, new materials, pharmaceuticals, and food, the particle size of pulverized materials directly determines the performance and value of the final product. Therefore, selecting a high-efficiency, stable micronizer and its reliable manufacturer and supplier is a crucial step for enterprises to enhance their core competitiveness.

Faced with numerous suppliers in the market, how do you make an informed choice? This article will guide you through understanding the qualities of a high-quality manufacturer.

I. Core Technology: The "Heart" of a High-Quality Micronizer

A top-tier micronizer manufacturer's core competitiveness lies in its technological strength. You should pay attention to the following:

• Pulverization Accuracy and Particle Size Distribution: Excellent equipment can achieve pulverization requirements of D97 < 10μm or even finer, with a concentrated particle size distribution, meeting your stringent standards for product consistency.

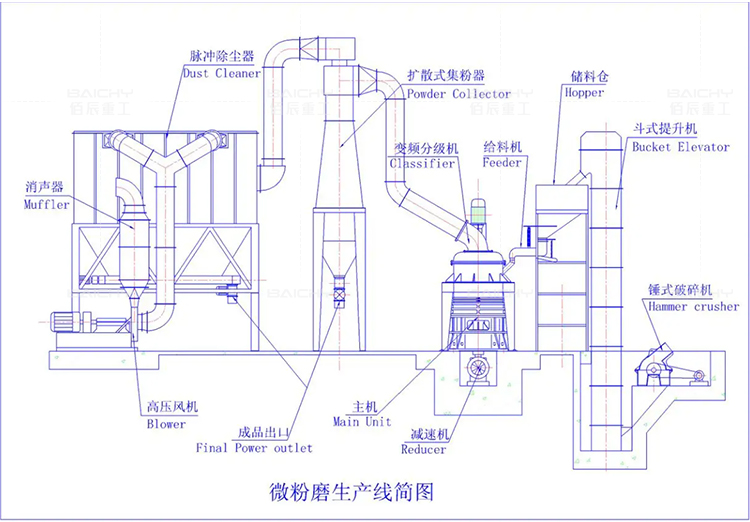

• Energy Consumption and Efficiency: Advanced pulverization principles (such as air jet milling, mechanical shearing, and vibratory milling) can achieve high output with low energy consumption, significantly reducing your operating costs.

• Temperature Rise Control: For heat-sensitive and low-melting-point materials, a good cooling system or cryogenic grinding technology is essential to effectively prevent material denaturation or adhesion.

II. Extensive Product Line: The Cornerstone for Meeting perse Needs

There is no one-size-fits-all equipment, only the most suitable solution. An excellent micronizer supplier should offer a variety of equipment options:

• Airflow Mill: Suitable for ultra-fine grinding of high-hardness, high-purity materials, with no media contamination and low temperature rise.

• Mechanical Mills (e.g., ball mills, vibratory mills): Suitable for large-scale, continuous production scenarios, offering high cost-effectiveness.

• Laboratory-Specific Models: Supporting your R&D and small-batch pilot production, ensuring a seamless transition from pilot testing to mass production.

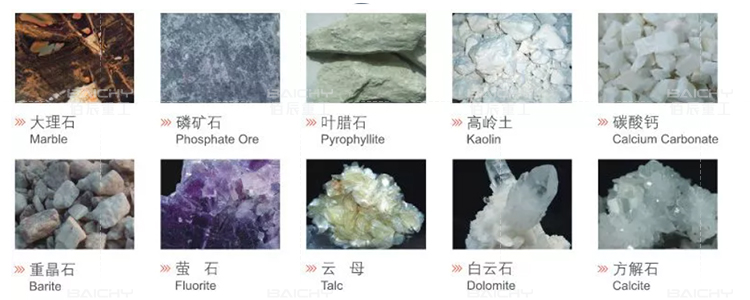

A strong product line means that the supplier can provide the most professional and economical customized solutions based on your material characteristics (hardness, moisture content, specific gravity, etc.) and production capacity requirements.

III. Beyond the Equipment Itself: Comprehensive Service Capabilities Determine Success

Choosing a supplier is not just about purchasing a piece of equipment, but about starting a long-term cooperative relationship. Please be sure to consider the following:

• Testing and Trial Grinding Services: Can you provide free testing machines for material trial grinding? This is the most direct way to verify the equipment's suitability.

• After-sales Service and Technical Support: Do you provide rapid global spare parts supply, installation, commissioning, and operation training? Response speed is crucial.

• Success Stories and Industry Reputation: Review the supplier's successful cases in your industry or similar material handling; customer testimonials are the best proof.

When choosing a micronizer manufacturer and supplier, please move beyond the misconception of "price is everything." Comprehensively consider their technical strength, product compatibility, and service guarantee system. A trustworthy partner will be a powerful support for improving product quality, reducing production costs, and gaining a market advantage.

Baichy Heavy Industry, as a leading expert in powder equipment solutions, has years of technical expertise and rich industry experience. We provide a full-process service from free testing and solution design to equipment manufacturing, installation, and commissioning. Contact us now to get your exclusive free trial grinding and technical solution!