7 key factors affecting the grinding performance of ball mills and optimization solutions

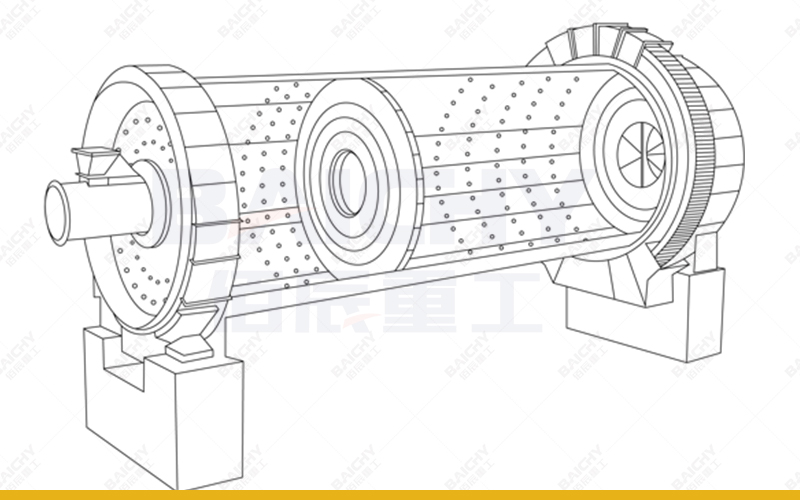

Ball mills are widely used in mining, building materials, chemical and other industries. Their grinding efficiency directly affects production efficiency and cost. However, many users have found that after the ball mill has been running for a period of time, the grinding effect decreases and the energy consumption increases. So, what factors affect the grinding performance of the ball mill? How to optimize to improve efficiency? This article will analyze the 7 key factors in detail and provide scientific optimization solutions.

1. Material properties (hardness, particle size, humidity)

• Hardness: The harder the material, the more difficult it is to grind, and the grinding media and rotation speed need to be adjusted.

• Initial particle size: Too large or too small feed particles will affect the grinding efficiency, and the crushing stage needs to be reasonably controlled.

• Humidity: Too high humidity can easily cause material adhesion and affect the movement of the grinding media. It is recommended to use drying or adjust the air volume.

Optimization solution: Select the appropriate ball mill type (such as wet grinding or dry grinding) according to the material characteristics, and adjust the feed particle size distribution.

2. Grinding media (material, size, filling rate)

• Material: Different materials such as steel balls, ceramic balls, and zirconia balls affect wear resistance and grinding effect.

• Size ratio: Large balls are used for coarse crushing, and small balls are used for fine grinding. Reasonable matching can improve efficiency.

• Filling rate: Usually controlled at 30%-50%. Too high will reduce the impact force, and too low will result in insufficient grinding.

Optimization plan: Use highly wear-resistant materials (such as high-chromium steel balls) and adjust the media ratio according to the grinding stage.

3. Ball mill speed (critical speed ratio)

• Too low speed: The grinding media cannot be effectively thrown off, and the grinding efficiency is low.

• Too high speed: The centrifugal force is too large, the media adheres to the cylinder wall, and loses the grinding effect.

• Optimum speed: Usually 65%-85% of the critical speed (critical speed formula: Nc = 42.3/√D, D is the cylinder diameter).

Optimization plan: Control the speed through frequency conversion speed regulation to meet the needs of different grinding stages.

4. Loading (ratio of material to medium)

• Too much material: insufficient grinding space, resulting in insufficient grinding.

• Too little material: increased collision between media, increased energy consumption but decreased efficiency.

• Optimal ratio: material accounts for 20%-30% of the cylinder volume, and medium accounts for 30%-50%.

Optimization plan: Regularly monitor the loading volume and use an automatic feeding system to maintain stable operation.

5. Grinding time

• Too short time: incomplete grinding, substandard product particle size.

• Too long time: increased energy consumption, which may cause over-grinding (too fine particles).

Optimization plan: Determine the optimal grinding time through experiments, and use grading equipment (such as cyclone separators) to improve efficiency.

6. Equipment structure and liner design

• Cylinder length-to-diameter ratio: long cylinders are suitable for fine grinding, and short cylinders are suitable for coarse crushing.

• Liner material: high manganese steel, rubber liner, etc. affect wear resistance and noise level.

• Discharge mode: overflow type (wet grinding) or grid type (dry grinding) affects the discharge efficiency.

Optimization plan: select the appropriate structure according to the process requirements, and regularly check the wear of the liner.

7. Maintenance and lubrication

• Poor bearing lubrication: leads to increased friction and increased energy consumption.

• Gear wear: affects transmission efficiency, increases vibration and noise.

• Regular maintenance: can prevent sudden failures and extend equipment life.

Optimization plan: formulate a standardized maintenance plan, use high-quality lubricants, and monitor equipment vibration.

Summary: How to improve the grinding efficiency of the ball mill?

• Optimize material properties: control feed particle size and humidity, and improve grinding adaptability.

• Scientifically proportion grinding media: reasonably select material, size and filling rate.

• Adjust the speed and loading amount: ensure effective impact of the medium to avoid ineffective energy consumption.

• Use advanced structure and maintenance: select wear-resistant liner and lubricate and overhaul regularly.

Through the above optimization measures, the grinding efficiency of the ball mill can be significantly improved, energy consumption can be reduced, and product quality can be improved. If you have specific working conditions, please consult professional engineers to obtain customized solutions!