What is a ball mill? Detailed explanation of working principle, types and application fields

Ball mill is a key grinding equipment widely used in mining, building materials, chemical industry, metallurgy and other industries. It is mainly used to crush materials to the required fineness. Whether it is ore beneficiation, cement production, or laboratory sample preparation, ball mills play an important role. This article will introduce the working principle, main types, application fields and purchase recommendations of ball mills in detail to help you fully understand this efficient grinding equipment.

1. Basic concept of ball mill

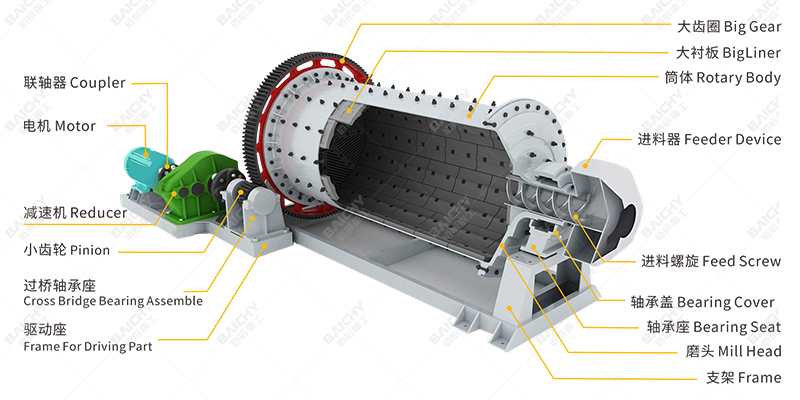

Ball mill is a mechanical equipment that uses steel balls or ceramic balls as grinding media, and rotates the cylinder to make the material and the grinding balls collide and rub against each other, thereby achieving crushing and mixing. Its main features include:

• Efficient grinding: suitable for dry grinding and wet grinding, and can handle materials of various hardness.

• Simple structure: mainly composed of cylinder, transmission device, feeding/discharging device, etc.

• Wide application: covering mining, cement, ceramics, chemicals, medicine and other industries.

2. Working principle of ball mill

The core working principle of ball mill is based on impact, friction and shearing:

• Loading: The material and grinding media (steel balls, ceramic balls, etc.) are loaded into the rotating cylinder together.

• Rotary grinding: The motor drives the cylinder to rotate, and the grinding media is lifted to a certain height under the action of centrifugal force and then falls, which has an impact and grinding effect on the material.

• Grading discharge: The fine particles after grinding are discharged through the screen or overflow, and the coarse particles continue to be ground until they meet the standard.

Key influencing factors:

• Speed: Too low (unable to lift the grinding balls) or too high (centrifugal motion) will affect the efficiency.

• Grinding media: steel balls, ceramic balls, zirconia balls, etc., affect the grinding effect and material purity.

• Filling rate: The ratio of grinding balls to materials, usually accounting for 30%-50% of the cylinder volume.

3. Main types of ball mills

Based on the structure and working mode, ball mills can be divided into the following categories:

| Type | Features | Applicable scenarios |

| Wet ball mill | Grinding with water to reduce dust and improve grinding efficiency | Ore dressing, ceramics, chemical slurry preparation |

| Dry ball mill | Waterless grinding, suitable for wet-proof materials | Cement, refractory materials, metal powders |

| Planetary ball mill | Multiple grinding tanks rotate at high speed at the same time, suitable for ultra-fine grinding | Laboratory, nanomaterials, battery materials |

| Cone ball mill | The cylinder is conical to improve the classification efficiency of the grinding medium | Medium and fine crushing operations, such as gold and copper mines |

| Energy-saving ball mill | Using frequency conversion technology to reduce energy consumption by more than 30% | Large mines, cement plants |

4. Application areas of ball mills

• Mineral dressing in mines: used for crushing and sorting metal ores such as gold, copper, and iron ore.

• Cement production: grinding raw materials such as limestone and slag to improve cement quality.

• Ceramic industry: preparation of high-purity ceramic powders, such as alumina, silicon carbide, etc.

• Chemical industry: production of fine chemical products such as pigments, coatings, pesticides, etc.

• Laboratory research: used for ultrafine grinding of nanomaterials, positive and negative electrode materials for batteries, etc.

5. How to choose a suitable ball mill?

The following factors should be considered when purchasing a ball mill:

✔ Material properties: hardness, humidity, particle size requirements (such as D50≤10μm).

✔ Production capacity requirements: small laboratory ball mill (0.5-50L) or industrial-grade ball mill (1-300t/h).

✔ Energy consumption control: energy-saving ball mills can reduce long-term operating costs.

✔ After-sales service: professional manufacturers provide installation and commissioning, technical support and accessories supply.

✔ Recommended brand: Baichy Heavy Industry (focusing on ball mills for 20 years, providing customized solutions)

As an indispensable grinding equipment in modern industry, ball mills are widely used in many fields due to their high efficiency and stable performance. Whether it is a large-scale mine or laboratory research and development, it is very important to choose the right ball mill type and parameters. If you have ball mill procurement or technical consultation needs, please contact Baichy Heavy Industry, we will provide you with a professional one-stop solution!

Consult now: 0086 15093222637 | Official website: www.baichychina.com