Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In the field of non-metallic mineral powder processing, choosing the right grinding equipment is crucial for production efficiency and economic benefits. For investors planning to build medium- to large-scale powder production lines or expanding existing production capacity, the 4R3216 Raymond mill is undoubtedly a highly anticipated model.

1. High Output and Strong Scale: A single unit can produce several tons per hour, effectively meeting the continuous production needs of medium-sized powder manufacturers and reducing per-ton production costs.

2. Relatively Optimized Energy Consumption: At high production volumes, its unit energy consumption is more economical than operating multiple smaller units in parallel.

3. Wide Adjustable Finished Product Particle Size Range: The finished product particle size is typically flexibly adjustable between 80 and 400 mesh, meeting the fineness requirements of various applications.

4. Stable and Reliable Operation: As a classic large-scale machine, its mature structural design and sturdy core components ensure continuous and stable production.

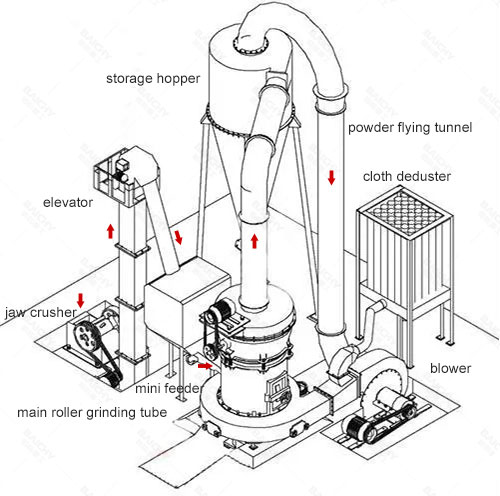

The Raymond mill is composed of the main frame, grinding roller, grinding ring, scraper blade, classifier, motor, ventilation device, analysis machine, blower, spring, belt, access door, etc.

The 4R3216 Raymond Mill's grinding process is an efficient closed-loop system consisting of four main stages:

1. Feeding and Crushing

• Large raw materials are coarsely crushed into smaller pieces by a jaw crusher.

• The The crushed material is conveyed by an elevator into a storage hopper and then fed evenly and continuously into the mill via a feeder.

2. Grinding and Drying: The material is crushed by rollers within the grinding chamber.

3. Classification and Sorting

• The pulverized powder is lifted by an airflow and sent to an analyzer for sorting.

• Qualified fine powder (reaching the set fineness) passes through the analyzer and proceeds to the next stage.

• Unqualified coarse powder is returned to the grinding chamber by the analyzer for re-grinding.

4. Product Collection and Purification

Qualified fine powder is carried by the airflow into a cyclone collector, where the majority settles and becomes the finished product. The gas containing trace dust is then deeply purified by a pulse dust collector and finally discharged as clean air by an induced draft fan.

| Model | Roller | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity T/Shaft | Power (Kw) | Dimension | |

|---|---|---|---|---|---|---|---|---|---|

| 4R | 3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 4-45 | 37 | 7100*5900*7900 |

These are the core specifications of this model:

"4R": This designation indicates the four grinding rollers within the mill. The number of rollers is a key factor in determining grinding capacity and output.

"3216": This is a specification code, typically referring to the size of the grinding rollers, which typically measures approximately 320 mm in diameter and 160 mm in height. This determines the contact area between the rollers and the grinding ring, directly impacting grinding efficiency.

The 4R3216 Raymond Mill typically produces a particle size range of 80 to 400 mesh (37 to 5 microns). Fineness adjustment is easy by adjusting the speed of the analyzer (analyzer) located above the main unit. The faster the speed, the finer the powder. The entire process requires no downtime, and the mill can be adjusted continuously during operation, making it easy to operate.

The 4R3216 Raymond mill is designed for non-metallic minerals with a Mohs hardness of 7 or less. The marble, gypsum, and barite you mentioned, as well as calcite, limestone, feldspar, and fluorite, are all within its processing range. If you are unsure whether your material is suitable, please provide a sample and we can conduct a free grinding test to determine the most suitable mill model and solution.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.