Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The 3R2715 Raymond millis our company's highly efficient and energy-saving grinding equipment, integrating proven technology with innovative design. Rather than pursuing extreme output, it strikes a perfect balance between efficiency, energy consumption, and investment costs. It is an excellent choice for small and medium-sized powder processing plants, new production lines, or specific material grinding projects.

1. High Efficiency and Energy Saving: Optimized transmission and grinding mechanisms significantly reduce energy consumption per unit of product, helping you control production costs.

2. High Powder Extraction Rate: A unique analyzer design ensures that qualified fine powders are quickly separated, resulting in a high screening rate and effectively increasing production output.

3. Stable Operation: A robust structure and durable core components ensure continuous operation and minimize downtime losses.

4. Easy Operation: Its user-friendly design makes daily operation and maintenance simple and easy to learn, reducing reliance on specialized technical expertise.

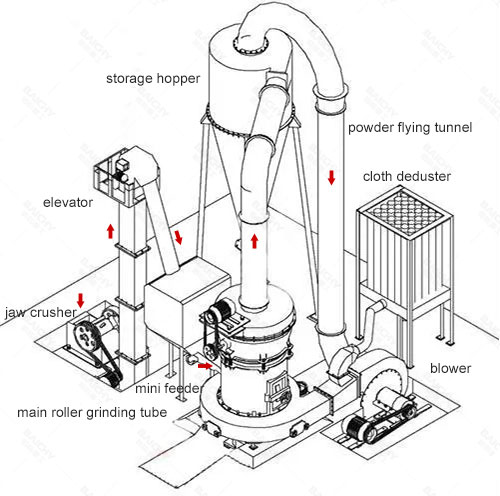

The Raymond mill is composed of the main frame, grinding roller, grinding ring, scraper blade, classifier, motor, ventilation device, analysis machine, blower, spring, belt, access door, etc.

The 3R2715 Raymond Mill's grinding process is an efficient closed-loop system consisting of four main stages:

1. Feeding and Crushing:

• Large raw materials are coarsely crushed into smaller pieces by a jaw crusher.

• The crushed material is conveyed by an elevator into a storage hopper and then fed evenly and continuously into the mill via a feeder.

2. Grinding and Drying: The material is crushed by rollers within the grinding chamber.

3. Classification and Sorting

• The pulverized powder is lifted by an airflow and sent to an analyzer for sorting.

• Qualified fine powder (reaching the set fineness) passes through the analyzer and proceeds to the next stage.

• Unqualified coarse powder is returned to the grinding chamber by the analyzer for re-grinding.

4. Product Collection and Purification

Qualified fine powder is carried by the airflow into a cyclone collector, where the majority settles and becomes the finished product. The gas containing trace dust is then deeply purified by a pulse dust collector and finally discharged as clean air by an induced draft fan.

| Model | Roller | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity T/Shaft | Power (Kw) | Dimension | |

|---|---|---|---|---|---|---|---|---|---|

| 3R | 1510 | 3 | 150*100 | 570*100 | 15 | 0.125-0.044 | 0.8-10 | 7.5 | 3200*1200*3800 |

| 2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 1-12 | 15 | 3500*3300*4500 | |

| 2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 1.5-20 | 18.5 | 4650*3600*5100 | |

| 2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 2-28 | 22 | 4700*3600*5100 | |

| 3015 | 3 | 300*150 | 875*150 | 25 | 0.125-0.044 | 2-35 | 30 | 5300*4100*5200 | |

A: Output is not a fixed value; it depends on the hardness, moisture content, and fineness of the material being ground. Generally speaking, when processing medium-hard materials (such as calcite) up to around 200 mesh, the hourly output ranges from 1 to 3 tons. The softer the material and the lower the fineness requirement, the higher the output. We recommend providing specific material information for an accurate estimate.

A: The finished fineness range for this model is typically between 80 and 325 mesh. This is achieved by adjusting the speed of the analyzer above the main unit: faster speeds increase the required fineness and result in a finer finished product; lower speeds produce a coarser product. This is one of the core operating principles of a Raymond Mill.

A: Absolutely. The 3R2715 model is designed specifically for small to medium-sized production needs. With its relatively low investment cost, compact footprint, and economical operation, it's an ideal entry-level choice for small processing plants or new projects.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.