Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The 4R3016 Raymond mill, also commonly known as the 4R3016 pendulum mill or Raymond mill, has four rollers, and the "3016" designation refers to the roller's specifications (related to roller diameter and height). The increased number and size of the rollers translates to a larger grinding area and greater processing capacity, making it ideally suited for medium- and larger-scale production.

1. Stable Structure: Its vertical design ensures a stable drive system, excellent vibration resistance, and smooth and reliable operation.

2. High Output: Compared to smaller models like the 3R and 2R mills, the 4R3016 offers significantly higher output, meeting the demands of continuous production.

3. Flexible Adjustment: The finished particle size can be flexibly adjusted between 80 and 400 mesh, enabling a single machine to meet diverse fineness requirements.

4. Environmentally friendly and low energy consumption: It adopts a high-efficiency pulse dust removal system with less dust overflow, high transmission efficiency and relatively low energy consumption.

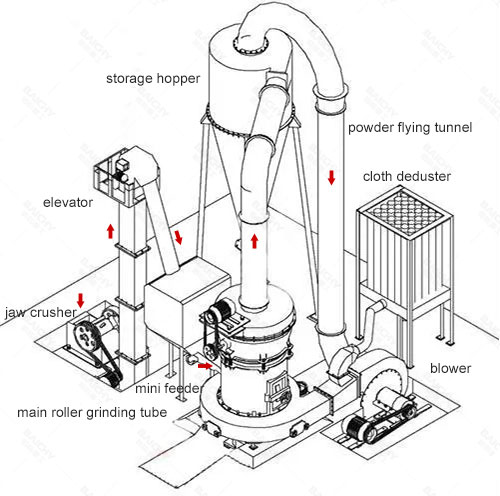

The Raymond mill is composed of the main frame, grinding roller, grinding ring, scraper blade, classifier, motor, ventilation device, analysis machine, blower, spring, belt, access door, etc.

The 4R3016 Raymond Mill's grinding process is an efficient closed-loop system consisting of four main stages:

1. Feeding and Crushing

• Large raw materials are coarsely crushed into smaller pieces by a jaw crusher.

• The crushed material is conveyed by an elevator into a storage hopper and then fed evenly and continuously into the mill via a feeder.2. Grinding and Drying:The material is crushed by rollers within the grinding chamber.

3. Classification and Sorting

• The pulverized powder is lifted by an airflow and sent to an analyzer for sorting.

• Qualified fine powder (reaching the set fineness) passes through the analyzer and proceeds to the next stage.

• Unqualified coarse powder is returned to the grinding chamber by the analyzer for re-grinding.

4. Product Collection and Purification

Qualified fine powder is carried by the airflow into a cyclone collector, where the majority settles and becomes the finished product. The gas containing trace dust is then deeply purified by a pulse dust collector and finally discharged as clean air by an induced draft fan.

| Model | Roller | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity T/Shaft | Power (Kw) | Dimension | |

|---|---|---|---|---|---|---|---|---|---|

| 4R | 3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 3-36 | 30 | 5400*4100*5200 |

| 3216 | 4 | 320*160 | 970*160 | 25 | 0.125-0.044 | 4-45 | 37 | 7100*5900*7900 | |

| 3220 | 4 | 320*200 | 970*200 | 25 | 0.125-0.044 | 4-55 | 45 | 9900*5800*1058 | |

The theoretical output of the 4R3016 is typically between 3 and 18 tons per hour, but this is highly dependent on the hardness, moisture content, and fineness of the milled material.

Common Causes and Solutions for Insufficient Output:

1. Material Property Changes: Check whether the current material is harder or wetter than previously. Excessively hard or wet material can significantly reduce output.

Solution: Ensure that the feed material hardness (Mohs scale 7 or below) and moisture content (recommended moisture content below 6%) meet requirements, and add a drying step if necessary.

2. Air Leakage in the Piping System: This is the most common cause. Poor seals at the powder lock and connecting flanges can lead to insufficient system negative pressure, preventing powder from being properly pumped out.

Solution: Perform a thorough inspection after shutting down the machine, using candles or smoke to locate leaks, and reseal the system.

3. Improper analyzer speed: To achieve excessively high fineness (e.g., above 400 mesh), the analyzer speed needs to be increased. This can cause more powder to be thrown back into the grinding mill for re-grinding, reducing yield.

Solution: While meeting production requirements, adjust the analyzer speed appropriately to find the optimal balance between yield and fineness.

4. Wear of consumable parts: Grinding efficiency drops sharply when the grinding roller, grinding ring, and scraper blades wear.

Solution: Regularly inspect and replace consumable parts.

1. Inspect the analyzer blades: The analyzer rotor and blades are key to fineness control. Blade wear or deformation directly leads to reduced classification accuracy.

Solution: Stop the machine for inspection and replace worn blades.

2. Adjust the analyzer speed: If fineness is insufficient, increase the analyzer speed appropriately. If fineness is too fine, resulting in low yield, reduce the speed appropriately. Check the fan air volume: If the damper is too open and the air speed is too high, it will carry away incompletely ground coarse particles, resulting in a coarse finished product.

Solution: Appropriately close the damper at the fan inlet.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.