Namibia has rich uranium resources, among which the Husab uranium mine is one of the largest uranium discoveries in the world in the past decade. The rich uranium resources provide strong support for Namibia's economic development and also provide important guarantees for China's energy security.

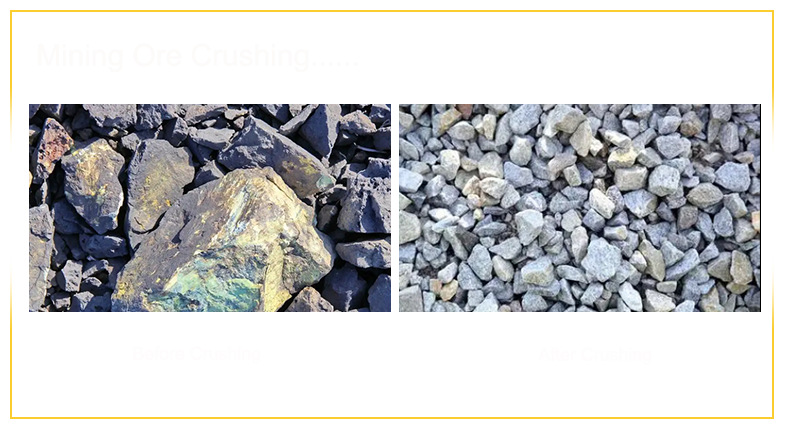

Mobile crushing stations play an important role in the uranium mining process. Mobile crushing stations have the advantages of strong flexibility, flexible configuration, and high production efficiency, and can adapt to the needs of different sites and materials. At the uranium mining site in Namibia, mobile crushing stations can be used for preliminary crushing and screening of uranium ore, providing convenience for subsequent processing and refining.

Advantages of mobile crushing stations:

1. Flexibility and mobility

2. High efficiency and energy saving

3. Flexible configuration and customized services

4. Integration and Intelligence

5. Environmental protection and safety