China Hammer Crusher Machine Manufacturer

In the mining and aggregate industry, Chinese hammer crusher manufacturers have become an indispensable force in the global market, thanks to their excellent cost-effectiveness, reliable quality, and rapid supply capabilities. As a mining crushing equipment manufacturer with twenty years of experience, we have not only witnessed this process but also participated in and promoted technological innovation and quality upgrades in the industry. This article will provide an in-depth analysis of the comprehensive strength of Chinese manufacturers, showcasing their unique advantages and value.

Core Advantages: Why Choose Chinese Hammer Crusher Manufacturers?

In the highly competitive global market, Chinese hammer crusher manufacturers do not rely solely on price. Their comprehensive advantages are a concentrated reflection of long-term technological accumulation, market feedback, and a complete industrial chain.

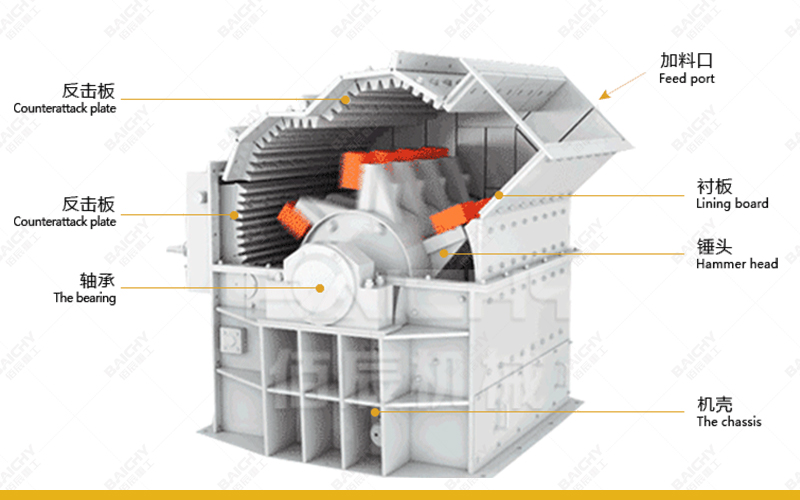

Structural diagram of a PC hammer crusher

Mature Technology and Extensive Experience

Twenty years of focus on the research and development and manufacturing of mining crushing equipment means we have a thorough understanding of the crushing processes for various materials (such as limestone, bluestone, and coal gangue). Our technical team continuously optimizes hammer head materials, rotor structure, and grate plate design to ensure that the equipment achieves efficient crushing while having a longer wear part life and lower cost per ton.

Complete Industrial Chain and Cost Control

China has the world's most complete mining equipment supply chain system. From special steel casting to precision machining, from core bearing procurement to intelligent electrical control system integration, the complete industrial chain enables us to achieve better cost control while ensuring high quality, providing customers with truly "value-for-money" equipment.

Highly Customized and Rapid Response

We understand that no two mining projects are exactly alike. Therefore, as an experienced hammer crusher manufacturer, we provide a full range of services from equipment selection and solution design to installation guidance. We can make targeted adjustments to the equipment based on your feed size, output requirements, capacity targets, and on-site working conditions to ensure efficient production line matching.

PC hammer crusher customer site

Success Stories: Proof of Strength

We have numerous successful cases worldwide; the following is a typical example:

• Project Location: A large cement raw material production line in Southeast Asia

• Challenge: Crushing high-humidity, sticky limestone; traditional equipment easily clogged the grate plates, leading to unstable production capacity.

• Our Solution: We provided a heavy-duty PCZ series hammer crusher, specifically adopting an anti-clogging grate plate design and a high-torque rotor. Meanwhile, the hammer heads are made of our exclusive high-chromium composite alloy material, increasing wear resistance by over 30%.

• Results: The equipment operates stably, and no clogging occurred even when the material moisture increased during the rainy season, ensuring the continuous and efficient operation of the entire production line. The customer is very satisfied with the output particle shape and capacity.

Equipment Recommendation: Core Product Series

As a seasoned manufacturer of mining crushing equipment, our hammer crusher product line is extensive:

• PC Series Ordinary Hammer Crusher: An economical and practical choice, suitable for medium and fine crushing of materials with a compressive strength of no more than 200MPa. It features a simple structure and easy maintenance.

• PCZ Series Heavy-Duty Hammer Crusher: A star product that achieves "one-step molding." It can directly crush materials with a side length of 1000-1200mm to less than 25mm in one go, significantly simplifying the process flow and reducing investment costs. It is the core choice for many sand and aggregate production lines.

• PCX Series High-Efficiency Fine Crusher: Focused on sand making and fine material production, it produces finer and more uniform output particle sizes, making it a powerful tool for increasing product added value and optimizing gradation.

Frequently Asked Questions (FAQ)

Q1: Compared with European brands, are Chinese-made hammer crushers reliable in quality?

A: Absolutely reliable. After twenty years of technology introduction, digestion, and re-innovation, leading Chinese manufacturers have reached internationally advanced levels in material science, dynamic balance testing, and manufacturing processes. Our use of high-standard bearings, laser cutting, and stress relief processes ensures the long-term operational stability of the equipment, and its core indicators (such as output, energy consumption, and wear part life) have strong international competitiveness.

Q2: What is the lifespan of wear parts (such as hammer heads)? Is procurement convenient?

A: We offer a variety of hammer head materials (such as high-manganese steel, high-chromium cast iron, multi-alloy steel, etc.) to choose from, depending on the crushed material. When crushing medium-hardness limestone, a set of hammer heads can typically last for tens of millions of tons. As the original manufacturer, we guarantee the rapid supply of original spare parts, and we have service points or partners in many parts of the world to ensure your peace of mind.

Q3: Do you provide installation, commissioning, and technical support services?

A: Yes, we provide a complete turnkey service. This includes initial site surveys and design, equipment installation guidance and commissioning, and training for local operation and maintenance personnel. We provide detailed English and Chinese operation manuals and offer remote online technical support to ensure that our customers can independently and proficiently operate and maintain the equipment.