PE 500x750 Jaw Crusher

In the field of mining crushing, the PE500x750 jaw crusher is undoubtedly the mainstay in the medium and coarse crushing stages. Its stability and output efficiency directly affect the profitability of the entire production line. However, have you ever been forced to shut down the entire line due to the sudden failure of a critical component, resulting in huge economic losses? Do you understand that the true value of equipment lies not only in its performance at the time of manufacture, but also in its operating and maintenance costs throughout its entire life cycle?

As seasoned professionals in the mining equipment industry, we deeply understand that to do a good job, one must first sharpen one's tools. The core of sharpening one's tools lies in a deep understanding of its internal components. Today, we present you with this detailed parts list for the PE500x750 jaw crusher. This is not just a list, but a health check of equipment health management and a strategic map for maximizing efficiency.

| Product Model | PE500x750 Jaw Crusher |

|---|---|

| Maximum Feed Size | ≤ 425 mm |

| Outlet Adiusting Range | 50-100 mm |

| Processing Capacity | 40-130tph |

| Motor Power | 45 kW |

| Core Structure | Deep cavity fracture |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Core Heart Components: Moving Jaw and Fixed Jaw Assembly

This is the direct executor of the crusher's crushing operations; its condition determines the crushing efficiency and product particle size.

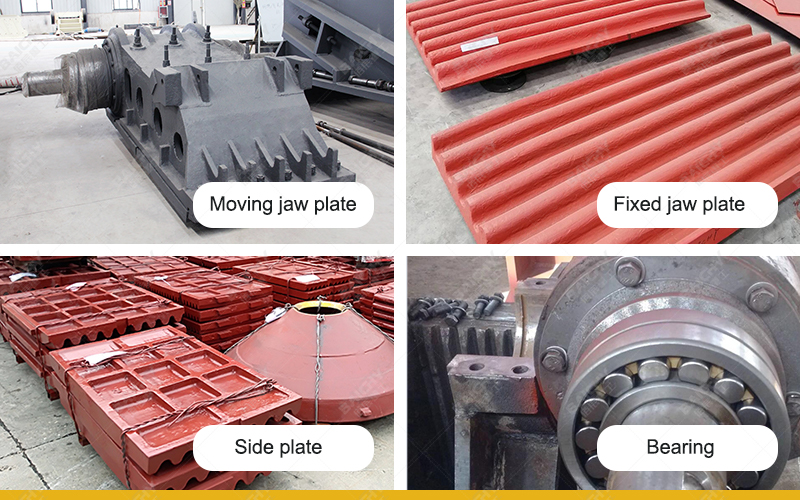

Wearing Parts Of PE500x750 Jaw Crusher

• Moving Jaw Plate/Fixed Jaw Plate (Tooth Plate): Made of high-manganese steel such as ZGMn13, it boasts extremely high wear resistance and impact resistance. The material, weight, and tooth profile specifications must be clearly stated in the list. We recommend customers select the optimal tooth profile based on the hardness of the material being crushed (e.g., granite, basalt, or limestone) and regularly check for wear, promptly reversing or replacing the tooth to maintain efficient output.

• Moving Jaw Assembly: Includes the moving jaw body, eccentric shaft bearings, etc. The structural strength of the moving jaw body and the selection of bearings directly affect the equipment's ability to withstand enormous impact loads.

II. Power Transmission and Core Moving Components: The Equipment's Spine and Joints

This part ensures the efficient and smooth conversion of the motor's power into the crushing motion of the moving jaw.

• Eccentric Shaft: As the spine of the crusher, its material (usually high-strength alloy steel such as 42CrMo), heat treatment process, and machining precision require extremely high standards. Our list will specify the shaft's dimensions, tolerances, and heat treatment hardness to ensure its fatigue strength.

• Bearings: Large self-aligning roller bearings are typically selected to withstand enormous radial and axial loads. The list will specify the bearing brand (e.g., international brands like SKF and FAG, or equivalent high-quality domestic bearings) and precise model number for customer convenience in sourcing.

• Flywheel and Grooved Reel: The flywheel stores energy, ensuring smooth crushing operations. As part of the belt drive, the groove dimensions and dynamic balance accuracy of the grooved reel are crucial.

III. Adjustment and Safety Devices: Precise Control and Overload Protection

This section reflects the equipment's user-friendly design and safety reliability.

• Thrust Plate (Toggle Plate): Not only transmits power but also acts as a mechanical fuse. When uncrushable materials (such as iron blocks) enter the chamber, the thrust plate will break first, protecting core components such as the eccentric shaft and moving jaw from damage. Its material and specifications will be clearly stated in the list.

• Discharge Port Adjustment Device: By adjusting shims or wedges, the position of the thrust plate can be changed, thereby precisely controlling the discharge particle size. A flexible and reliable adjustment device greatly improves production flexibility. IV. Why Choose Our Parts and Services?

We offer more than just a parts list; we provide a complete solution:

1. Original Factory Quality, Precise Match: All parts are manufactured strictly according to the precision and material requirements of the drawings, ensuring a perfect fit with your PE500x750 and eliminating secondary damage caused by dimensional inconsistencies.

2. Supply Chain Advantage, Rapid Response: As a professional manufacturer, we have a stable supply of raw materials and production lines, enabling us to provide customers with the most competitive prices and fast delivery times, minimizing your downtime.

3. Expert-Level Technical Support: Our team can provide you with scientific spare parts planning and preventative maintenance suggestions based on your specific operating conditions (material properties, working hours, etc.), transforming reactive maintenance into proactive management.

Mastering the PE500x750 parts list is the first step towards intelligent and refined equipment management. It allows you to shift from passively responding to failures to proactively planning maintenance, thereby achieving higher equipment utilization, lower crushing costs per ton, and a longer equipment lifespan. Contact our experts now for a complete official parts list and customized maintenance solutions for your specific operating conditions, ensuring your crusher always performs at its peak!

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.