High-efficiency sludge drying rotary kiln dryer | Energy saving 30%·Moisture content ≤ 10%·Customized solution

Overview of rotary kiln products

Traditional sludge treatment methods (such as landfill and composting) face high costs and secondary pollution risks. XX brand rotary kiln dryer adopts high-temperature indirect heating technology to reduce the sludge moisture content from 80% to below 10%, and reduce the volume by 50%. It can be directly used for incineration power generation or building materials, and complies with the Ministry of Environmental Protection's "Technical Specifications for Sludge Treatment and Disposal" (GB/T 23485-2023).

Core advantages(bold keywords):

• Improved thermal efficiency: multi-layer heat exchange structure design, energy consumption is reduced by 30% compared with traditional equipment

• No tail gas pollution: closed drying + tail gas purification system, meeting the "Comprehensive Emission Standards for Air Pollutants"

• Intelligent control: PLC automatically adjusts temperature (200-600℃ adjustable), speed (0.5-5r/min)

Technical parameter table

| Parameter item | Standard model (RTO-100) | Customized model (RTO-200) |

| Processing capacity | 5 tons/day | 10-20 tons/day |

| Feed moisture content | ≤80% | ≤85% |

| Discharge moisture content | ≤10% | ≤8% |

| Heat source selection | Natural gas/steam/electricity | Biogas/industrial waste heat |

| Occupancy area | 15㎡ | 25㎡ |

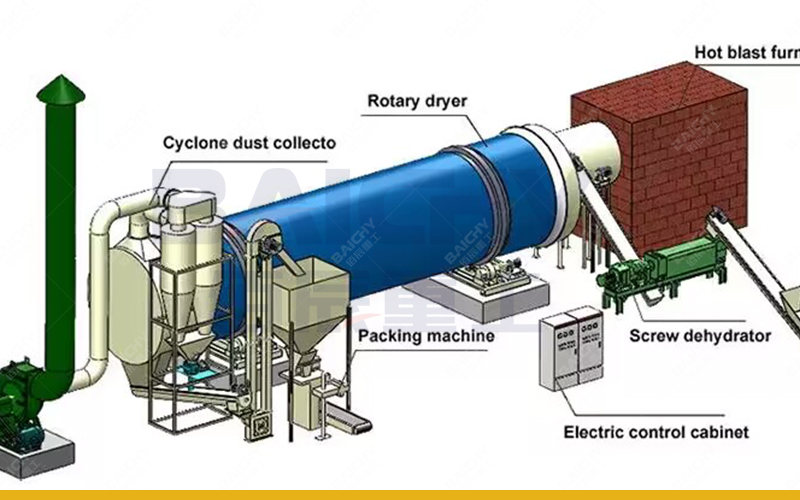

Three-stage drying process (with flow chart):

1. Preheating section: wet sludge enters the rotary kiln through the screw feeder and initially contacts with 200℃ hot air;

2. Decomposition section: the kiln body is tilted 3-5° and rotates slowly, the sludge evaporates water at 500℃ high temperature, and the organic matter is cracked;

3. Cooling section: the dried sludge is discharged through the discharge port, and the exhaust gas meets the emission standards after cyclone dust removal + activated carbon adsorption.

Application scenarios

1. Municipal sludge: sludge reduction in sewage treatment plants (attached with a sewage plant case: treatment cost reduced by ¥120/ton)

2. Industrial sludge: harmless treatment of hazardous waste sludge in electroplating, printing and dyeing, and pharmaceutical industries

3. Resource utilization: the calorific value of sludge after drying reaches 1500kcal/kg, which can be used for cement kiln co-disposal

Frequently Asked Questions

Q: Will the treatment of sticky sludge stick to the wall?

A: Patented anti-sticking lining + chain crushing device is used, and the wall sticking rate is less than 5%.

Q: How to ensure the life of the equipment?

A: The kiln body is made of 310S stainless steel, corrosion-resistant design, and a 10-year warranty is promised for core components.

Get exclusive solutions:

24-hour hotline: 0086 15093222637

Send the sludge test report to [email protected] to get the drying test data for free