Mineral rotary dryer is a continuous, large-scale drying device that uses a rotating drum to ensure full contact between the material and hot air. Its core advantages include large processing capacity, stable operation, and strong adaptability. It can efficiently dry various mineral raw materials such as quartz sand, mineral powder, and metal concentrates, making it an ideal drying solution for industries such as mineral processing and building materials.

This article will provide an in-depth analysis of our two main products—the single-drum dryer and the triple-drum dryer—from technical parameters and application scenarios to core advantages and working principles, helping you make the wisest decision.

I. Equipment Overview and Application Scenarios

Before making your choice, it's essential to understand the basic positioning of each type of equipment.

• Single-Drum Dryer: An Economical and Reliable "All-Round Warrior"

◦ Equipment Overview: As a traditional and technologically mature drying equipment, the single-drum dryer is renowned for its simple structure, stable operation, large processing capacity, and strong adaptability. Like a tireless "old ox," it maintains stable output under various harsh operating conditions.

◦ Applicable Materials: Particularly suitable for materials with large throughput, such as slag, clay, coal slime, metal powder, and limestone, where the requirements for drying uniformity are not extremely stringent.

◦ Application Scenarios: Suitable for large-scale projects such as cement plants, steel plants, and mineral processing plants with relatively limited investment budgets but seeking continuous, stable, and large-scale production.

• Three-Cylinder Dryer: A High-Efficiency, Energy-Saving "Technological Pioneer"

◦ Equipment Overview: The three-cylinder dryer is a product of technological innovation, employing a three-layer nested cylinder structure. Its core advantages lie in its extremely high thermal efficiency, minimal footprint, and excellent environmental performance, making it an ideal choice for those seeking energy conservation, emission reduction, and intensive production.

◦ Applicable Materials: Perfectly suited for materials requiring uniform drying and particle size, such as quartz sand, yellow sand, mineral powder, fertilizer, and feed.

◦ Application Scenarios: Modern factories with strict environmental and energy consumption requirements, upgrade and renovation projects with limited space, and the fine chemical industry requiring precise control of finished product moisture content.

II. Product Introduction and Core Advantages

1. Baichy Single-Cylinder Dryer

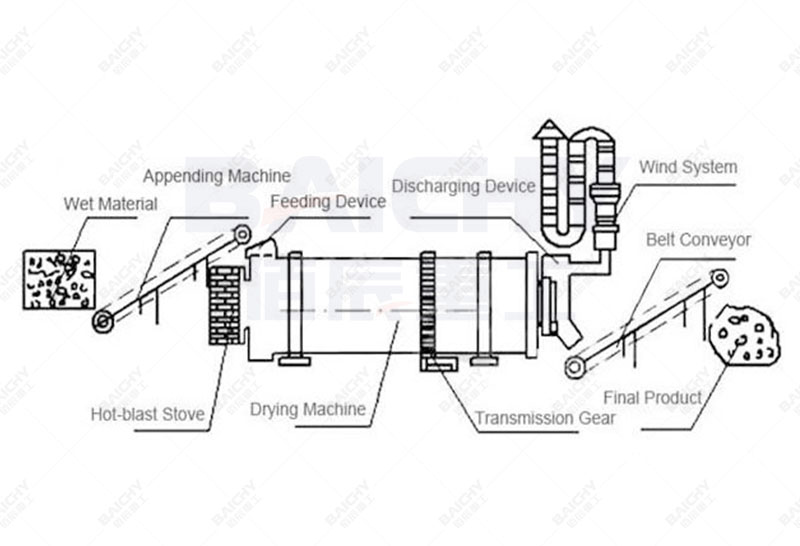

• Product Introduction: The Baichy single-cylinder dryer consists of a rotating body, lifting plates, a transmission device, a support device, and sealing rings. The cylinder is slightly inclined; material enters from the upper end and is continuously lifted and scattered by the lifting plates inside the cylinder, making full contact with hot air and gradually moving towards the lower end to complete the drying process.

• Four Core Advantages:

1. Robust and Durable Structure: Utilizing high-quality steel plates and large-scale gear hobbing technology, key components undergo wear-resistant treatment, resulting in a long service life and stable 24-hour continuous operation.

2. Large Processing Capacity and Strong Adaptability: The large cylinder space can handle various material forms, including lumpy, granular, and sticky materials, and is not sensitive to fluctuations in feed moisture content.

3. Simple Operation and Easy Maintenance: Mature technology, low barrier to automation, simple daily maintenance, and low operating costs.

4. Low Investment Cost and High Return on Investment: Relatively low initial purchase and installation costs make it a highly cost-effective choice for budget-sensitive customers.

2. Baichy Three-Cylinder Dryer

• Product Introduction: The Baichy three-cylinder dryer consists of three concentric nested cylinders of different diameters. Materials pass sequentially through the inner, middle, and outer cylinders, undergoing a complex heat exchange process involving three stages: preheating, drying, and cooling. This step-by-step utilization of heat energy results in extremely high efficiency.

• Four Core Advantages:

1. Significant Energy Saving: The unique structure allows for the recycling of heat energy, increasing thermal efficiency by over 40% compared to traditional single-drum dryers, significantly reducing fuel costs.

2. Small Footprint: The nested three-drum design makes the structure very compact, occupying only one-third the space of a single-drum dryer with the same output, greatly saving on infrastructure investment.

3. High Drying Quality: The material travels a long distance within the drum, ensuring thorough and gentle heat exchange, resulting in uniform moisture content and stable quality in the finished product.

4. Excellent Environmental Performance: Excellent overall sealing minimizes heat loss and allows for easy integration with various dust removal equipment, meeting stringent environmental emission standards.

III. Working Principle and Core Components

• Single-Drum Dryer Working Principle: Follows the "co-current" or "counter-current" drying principle. Material enters the drum in the same or opposite direction as the hot air. Under the rotation of the drum and the action of the lifting plates, a uniform material curtain is formed, exchanging heat and mass with the hot air. Moisture continuously evaporates, and finally, the dried material is discharged from the outlet.

• Three-Cylinder Dryer Working Principle: Material first enters the innermost cylinder, where it is heated by high-temperature hot air flowing in the same direction. It then flows back into the middle cylinder for counter-current drying. Finally, it reaches the outer cylinder, where it exchanges heat with the incoming cold air for cooling. The entire process achieves a closed loop of "self-preheating - main drying - waste heat recovery," maximizing thermal energy utilization.

• Core Components (General):

◦ Cylinder: The main body of the equipment, made of heat-resistant steel plate.

◦ Support Rollers and Baffle Rollers: Support the cylinder and limit its axial movement, ensuring smooth operation.

◦ Transmission Device: Includes motor, reducer, gears, etc., providing rotational power.

◦ Lifting Plate System: A core component responsible for lifting and dispersing materials, forming a material curtain.

◦ Sealing Device: Prevents air and material leakage, ensuring thermal efficiency and a safe working environment.

◦ Hot Air Furnace/Heating System: Provides a heat source (can be customized according to customer needs, using coal, natural gas, oil, etc.).

IV. Technical Parameters and Selection Reference

Note: The following are examples of common models; specific parameters need to be customized according to material characteristics.

| Equipment Model | Feed Size (mm) | Motor power (kW) | Production Capacity (tons/day) | Examples of applicable materials |

| Single-Cylinder Dryer Φ2.2×14m | ≤50 | 18.5 | 80-100 | Slag, Clay |

| Single-Cylinder Dryer Φ3.0×20m | ≤60 | 45 | 180-220 | Coal Slime, Red Mud |

| Triple-Cylinder Dryer Φ1.5×12m | ≤30 | 11 | 40-50 | Quartz Sand, Yellow Sand |

| Triple-Cylinder Dryer Φ2.2×16m | ≤35 | 22 | 90-110 | Mineral Powder, Fertilizer |

V. Case Study: A Wise Choice for a Quartz Sand Plant

• Customer Pain Points: A large quartz sand plant in South China had outdated equipment with high energy consumption and pollution, and the plant layout was already full, making it impossible to expand with larger equipment.

• Baichy Solution: We recommend using a Φ2.2×16m three-cylinder dryer, leveraging its small footprint and energy-efficient advantages to perfectly replace the existing production line.

• Results: After the equipment was put into operation, fuel costs decreased by 45% year-on-year, floor space was reduced by 60%, and the finished sand had uniform and stable moisture content, improved quality, and fully met environmental protection requirements. The customer was very satisfied with the return on investment.

VI. Frequently Asked Questions (FAQ)

1. Q: Which is more suitable for me, a single-cylinder or a three-cylinder dryer?

◦ A: It depends on your core needs. If you have a limited budget, pursue high throughput, and have ample space, choose a single-cylinder dryer. If you value energy saving and consumption reduction, have limited space, and pursue advanced technology, choose a three-cylinder dryer. Please provide your material and production capacity information, and our engineers will select the appropriate model for you free of charge.

2. Q: Can the equipment be customized for my specific materials?

◦ A: Of course. One of Baichy Heavy Industry's core advantages is non-standard customization. We can customize the lifting plate type, cylinder material, and thermal system according to your material characteristics (such as initial moisture content, viscosity, acidity/alkalinity, etc.).

3. Q: Do you provide installation services?

◦ A: We provide a complete "turnkey" service, from scheme design, equipment manufacturing, installation guidance, commissioning and operation to personnel training, ensuring the equipment operates at its best on-site.

4. Q: What is the delivery time for the equipment?

◦ A: Standard models typically take 30-45 days. Customized equipment may take slightly longer depending on its complexity. We will sign a rigorous contract with you to ensure on-time delivery.

Choosing Baichy is not just choosing a high-quality drying equipment, but also choosing a trustworthy long-term partner. We are committed to creating maximum value for every investment you make through professional technology and dedicated service.