Quartz sand, an indispensable key raw material in industries such as glass, ceramics, casting, electronics, and photovoltaics, directly determines the quality of end products. A well-configured quartz sand production line is the core guarantee for the stable production of high-purity, high-specification quartz sand.

This article will take you through an in-depth understanding of the composition and core processes of a quartz sand production line.

Core Content:

1. What is a Quartz Sand Production Line?

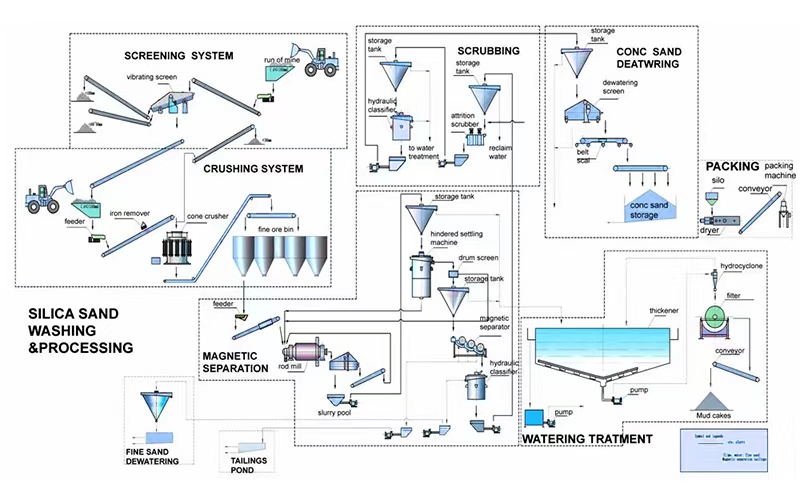

A quartz sand production line is a systematic engineering project that uses a series of coordinated industrial equipment to process raw quartz ore through crushing, sand making, screening, and washing, ultimately obtaining finished quartz sand with different particle sizes and purity requirements. A modern production line not only pursues efficiency but also emphasizes environmental protection, energy conservation, and automation.

2. Six Core Processes of a Quartz Sand Production Line

• Coarse Crushing: Large pieces of quartz stone are fed into a jaw crusher by a vibrating feeder for the first "coarse processing," crushing the raw material to approximately 100-200mm.

• Medium and Fine Crushing: The coarsely crushed stone enters a cone crusher or impact crusher for medium and fine crushing, producing materials with more uniform particle size (typically <40mm), preparing them for the sand making stage.

• Core Sand Making Stage: The material enters a vertical shaft impact crusher, where it is accelerated and thrown out by a high-speed rotating impeller, colliding and rubbing against surrounding materials to achieve a "stone-on-stone" crushing and shaping effect, producing high-quality manufactured sand with rounded particles.

• Precision Screening and Grading: The mixture after sand making is graded by a circular vibrating screen. Sand of qualified particle size enters the next stage, while unqualified coarse material is returned to the sand making machine for further processing, forming a closed-loop cycle to ensure controllable particle size of the finished product.

• Cleaning and Washing (Optional but Important): For high-purity quartz sand, a wheel bucket sand washer or spiral sand washer is used for washing to effectively remove impurities such as mud and dust, significantly improving product grade and market value.

• Dehydration and Drying: Quartz sand produced using the wet process requires dehydration (e.g., using dehydration screens) or subsequent drying treatment for storage and transportation.

Investing in a well-designed quartz sand production line is crucial for gaining market competitiveness. Choosing the right equipment supplier and optimizing the process flow can significantly improve production efficiency and product sand yield, while also reducing operating costs, achieving a win-win situation for both economic and environmental benefits.