Spring Cone Crusher

As a manufacturer with 20 years of experience in producing mining crushing equipment, we deeply understand the importance of reliable and efficient crushing equipment for mining production lines. Among numerous crushing equipment options, the PYB900 spring cone crusher, with its unique structural design, stable performance, and wide applicability, has become a mainstay in medium and fine crushing operations.

This article, drawing on our twenty years of technical accumulation and practical experience, will provide an in-depth analysis of the structural characteristics, performance advantages, and maintenance points of the PYB900 spring cone crusher, offering professional reference for mining enterprises in equipment selection and efficient production.

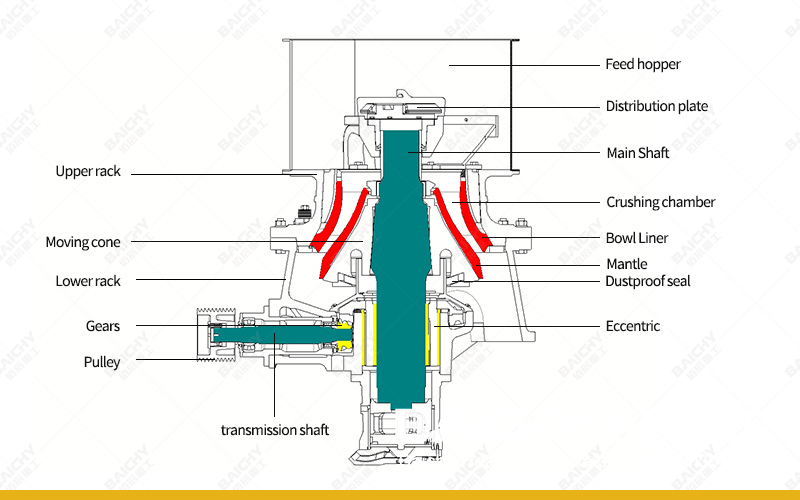

Structural diagram of a spring-loaded cone fracture

PYB900 Spring Cone Crusher Core Structure and Working Principle

The PYB900 is a medium-sized spring cone crusher. In its model name, P represents the crusher type, Y represents the cone type, B represents the standard type, and 900 refers to the diameter of the bottom of the moving cone (unit: millimeters). Its core design utilizes a spring safety device for overload protection. This ensures that when the equipment encounters uncrushable foreign objects or excessive iron, the object can be discharged by widening the discharge opening. The spring then automatically resets the device, effectively preventing damage.

Its working principle is as follows: The motor drives the eccentric sleeve to rotate via a drive shaft and bevel gears. The moving cone, driven by the eccentric sleeve, performs a gyratory motion, causing the crushing wall to move closer to and further away from the grinding chamber wall. The material is crushed within the crushing chamber by compression, bending, and shearing. Material meeting the particle size requirements is discharged from the bottom under gravity.

Performance Parameters and Applications Overview

To more intuitively demonstrate the technical specifications of the PYB900, we have compiled its core parameters table:

| Parameter Item | Technical Specifications/Description |

| Model | PYB900 |

| Diameter of Moving Cone Bottom | 900 mm |

| Maximum Feed Size | ≤115 mm |

| Discharge Opening Adjustment Range | 15-50 mm |

| Processing Capacity | 50-90 t/h |

| Spindle Speed | 333 rpm |

| Motor Power | 55 kW |

| Total Weight (Approx.) | 11.2 t |

| Dimensions (L×W×H) | 2692×1640×2350 mm |

Main Applications:

• Mining Industry: Medium and fine crushing of ores with medium to high hardness (such as granite, basalt, quartz, etc.).

• Building Materials Industry: Production of building aggregates and manufactured sand.

• Metallurgical Industry: Crushing metallurgical slag and other materials.

• Road Construction Industry: Providing high-quality roadbed materials.

In-depth Analysis of Advantages Based on 20 Years of Manufacturing Experience

With two decades of experience in design, manufacturing, and field service, we have continuously optimized the PYB900 spring cone crusher, giving it the following outstanding advantages:

1. Stable and Reliable Operation, Long Service Life

◦ Robust Structural Design: Utilizing a heavy-duty frame and high-strength spindle, ensuring the stability of the equipment under continuous high-load operation.

◦ Upgraded Wear Resistance of Key Components: Both the crushing wall (moving cone liner) and the mantle wall (fixed cone liner) are made of high-manganese steel, and more wear-resistant alloys can be selected according to the material characteristics. This is a significant optimization based on our years of experience.

2. Spring Overload Protection, Safe and Intelligent

◦ This is the core feature that distinguishes the spring cone crusher from the hydraulic cone crusher. When uncrushable materials enter the chamber, the spring system provides cushioning and allows the fixed cone to rise and expel the foreign objects, then automatically resets, protecting the main unit from damage and reducing the risk of unexpected downtime.

3. Relatively Simple Maintenance and Controllable Costs

◦ The structure is relatively mature, making it easier for maintenance personnel to grasp its core principles. The independent lubrication system and clear maintenance points result in lower daily maintenance costs compared to the more complex hydraulic cone crusher.

4. Uniform Output Particle Size and Good Product Particle Shape

◦ The layered crushing principle subjects the material to multiple compressions and impacts within the chamber, resulting in a lower content of needle-like and flaky particles and a more cubic product particle shape, meeting the requirements for high-quality aggregates.

The PYB900 spring cone crusher, as a classic medium crushing equipment, perfectly balances performance, reliability, and economy. While it may lack the fully automatic adjustment functions of the latest hydraulic cone crushers, its simple structure, robust durability, and convenient maintenance make it a reliable choice in many mines and quarries. Our twenty years of manufacturing experience has been a process of continuously refining, stabilizing, and ensuring the reliability of such classic equipment. Choosing a reliable PYB900 is not just choosing a piece of equipment, but also choosing a production guarantee derived from long-term professional accumulation.