In numerous fields such as mining, aggregate production, and construction waste treatment, primary crushing (coarse crushing) is the choke point of the entire production process. Its efficiency and stability directly determine the smoothness of subsequent processes and the economic benefits of the final product. Among many primary crushing equipment, there is a shining star that has withstood decades of market testing and is still widely chosen by customers worldwide the PE 600×900 jaw crusher.

This equipment is named for its 600mm×900mm feed opening size, a model that has almost become synonymous with medium-sized jaw crushers. Why has it become such a timeless classic? Today, let us, from the perspective of a seasoned industry professional, provide an in-depth analysis of the excellence of the PE 600×900.

1. Core Advantages: Why Choose the PE 600×900?

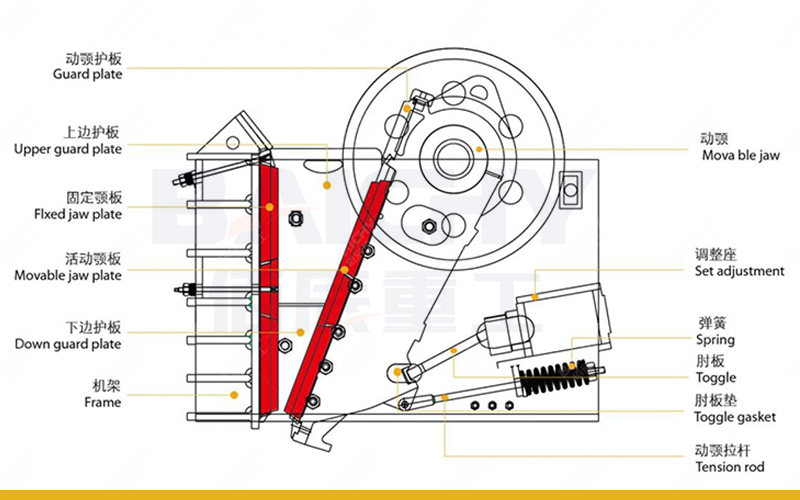

• Robust Structure, Durable: The frame is welded from high-quality, high-strength steel plates, resulting in a stable structure with high compressive strength, capable of withstanding enormous crushing forces and impact loads. The well-designed moving jaw assembly and the large forging of the eccentric shaft ensure an exceptionally long service life under harsh operating conditions.

• High crushing ratio and uniform output: The classic V-shaped crushing chamber design subjects materials to multiple actions such as compression, rubbing, and grinding within the chamber, achieving an extremely high crushing ratio. By adjusting the discharge port between the jaw plates, the finished particle size can be easily controlled, producing aggregates with excellent particle shape and reasonable gradation, reducing the burden on subsequent medium and fine crushing.

• High processing capacity and excellent efficiency: Under standard operating conditions, the PE 600×900 has a processing capacity of 50-180 tons per hour, making it an ideal choice for medium-sized production lines. Its high throughput effectively ensures the continuity of upstream feeding, avoiding production line shutdowns caused by bottlenecks in the coarse crushing stage.

• Low operating costs and easy maintenance: The equipment design fully considers ease of maintenance. Wear parts such as the jaw plates are made of wear-resistant manganese steel, resulting in a long replacement cycle. The unique toggle plate design not only transmits power but also automatically breaks under overload conditions, acting as a fuse to effectively protect the core components of the main unit from damage and significantly reduce unexpected maintenance costs.

• Wide Material Adaptability: Whether it's high-hardness ores like granite, basalt, and quartz, or medium-hardness materials like limestone and bluestone, the PE 600×900 can handle them with ease, demonstrating strong adaptability.

2. Core Application Scenarios: Where Does It Shine?

• Small and Medium-Sized Sand and Gravel Aggregate Production Lines: As a core coarse crushing device, it provides a stable supply of qualified primary aggregates for the entire production line.

• Mining: Used for the initial crushing of raw ore, breaking large pieces of raw ore to a size suitable for transportation or further crushing.

• Construction Waste Resource Utilization: Its powerful force easily crushes concrete blocks, bricks, and other construction waste, a crucial first step in turning waste into treasure.

• Metallurgy, Chemical, and Building Materials Industries: Used for the initial processing of raw materials.

| Product Name | PE600x900 Jaw Crusher |

|---|---|

| Brand | Baichy Heavy Industry |

| Place of Origin | Zhengzhou,China |

| Type | Jaw Crusher |

| Capacity | 90-180tph |

| Motor Type | AC Motor |

| Motor Power | 55Kw |

| Application | Mines and quarries |

| Materials | Ores and hard materials |

| OEM/ODM | Acceptatble |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Customization options | customized on demand,sample processing... |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

3. Investment Value Analysis: A Wise Choice for High Returns

For investors, the PE 600×900 is an extremely cost-effective piece of equipment. Its initial purchase cost is relatively reasonable, while its superior reliability and low maintenance costs ensure a very low total cost of ownership over its lifecycle. Choosing it means choosing stable output, controllable operating expenses, and long-term reliable production assurance, providing a solid foundation for a rapid return on investment.

The PE 600×900 jaw crusher is more than just a piece of equipment; it's a symbol of efficiency, reliability, and value. With its simple and unpretentious structure, it embodies the core value of industrial equipment. If you are planning or upgrading a medium-sized crushing production line, the PE 600×900 is undoubtedly your most reliable partner for the primary crushing stage. Contact us for customized technical solutions and quotations, and let this evergreen of the industry inject strong momentum into your business growth!