PE500x750 Jaw Crusher

The PE500X750, a benchmark model with a classic 750x500mm feed inlet diameter, has withstood the test of the market and remains highly favored. Today, we will go beyond a simple list of parameters and delve into its irreplaceable core advantages from four dimensions: design, efficiency, reliability, and return on investment.

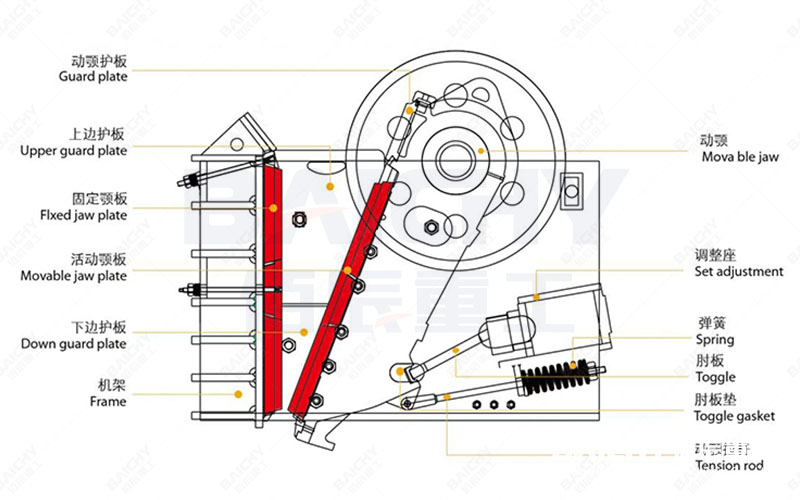

I. Structure of the PE500X750

The PE500X750 adheres to the engineering truth of the simpler, the more reliable.

PE500x750 jaw crusher structural diagram

1. Integral Welded Frame

Made of high-quality, high-strength steel plates and welded together, and subjected to rigorous stress relief treatment. Compared to partially assembled frames, its overall structure is stronger, capable of withstanding enormous crushing loads, effectively preventing deformation and fatigue cracking under long-term high-load operation, providing the equipment with a robust and durable foundation.

2. Moving Jaw Assembly and Heavy-Duty Eccentric Shaft

The moving jaw components are precisely calculated and optimized, with balanced mass and high inertia, ensuring a higher crushing ratio. The eccentric shaft is forged from high-strength alloy steel, undergoing flaw detection and precision machining to ensure smooth transmission and durability—the source of the equipment's ability to handle even the toughest materials.

3. Double Toggle Plate Design

This design not only transmits crushing force but also plays a crucial role in overload protection. When uncrushable materials (such as iron blocks) enter the crushing chamber, the toggle plate breaks first, protecting the core moving jaw, bearings, and frame from catastrophic damage and minimizing losses from unexpected downtime.

II. Superior Efficiency and Controllable Particle Shape

1. Deep Cavity Crushing, Superior Output

The optimized crushing chamber design achieves greater crushing depth and unparalleled throughput with the same power and feed inlet size. The 500x750mm feed inlet easily handles large stones up to 500mm in size, ensuring efficient primary crushing and providing a stable and sufficient material source for subsequent secondary crushing.

2. Adjustable Discharge Port, Excellent Particle Shape

The wedge-type discharge port adjustment device is simple, reliable, and has a wide adjustment range. Users can quickly and accurately adjust the discharge particle size according to downstream equipment requirements and final aggregate specifications. The unique toothed plate curve design not only improves crushing efficiency but also promotes the layered crushing of stone within the chamber, effectively reducing the content of needle-like and flaky particles, producing more cubic high-quality aggregate with a higher market price.

III. Durable and Economical to Maintain

For savvy investors, the purchase cost of equipment is only the tip of the iceberg; long-term maintenance costs, the lifespan of wearing parts, and downtime are the real cost pitfalls.

1. Long Lifespan of Core Components

Large cast steel bearing seats and high-quality self-aligning roller bearings provide strong radial load-bearing capacity and a lifespan far exceeding that of ordinary bearings. The high-manganese steel cast moving and fixed jaw teeth are highly wear-resistant and have a long replacement cycle.

2. Simple and Low-Cost Maintenance

The structural design fully considers ease of maintenance. The centralized lubrication system makes daily maintenance convenient. Highly standardized wear parts (such as jaw plates and toggle plates) facilitate convenient procurement and controllable costs. Modular design allows for faster replacement of critical components, significantly reducing planned and unexpected downtime.

PE500X750 A Cornerstone of Wealth for Prudent Investors

The PE500X750 jaw crusher may not be the most cool model on the specifications sheet, but its durable structure, stable and efficient output, and economical operating costs perfectly exemplify value investing. It represents a stable and pragmatic production philosophy, making it a wise choice for quarries and aggregate producers seeking long-term stable operation and valuing return on investment.

Choosing the PE500X750 is not just choosing a piece of equipment, but also choosing a trustworthy partner. It will serve as the core heart of your production line, continuously injecting strong momentum into your business, protecting it, and creating a brilliant future together.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.