We will take the core of a large-scale building materials project in Indonesia a 100-150 ton/hour andesite crushing production line as an example to deeply analyze how to tailor a high-efficiency, durable, and high-return hard rock crushing solution for our clients.

I. In-depth Understanding of Andesite Characteristics and Challenges in the Indonesian Market

Andesite, a neutral calc-alkaline extrusive rock, is characterized by high hardness (Mohs hardness of 6-7), high silica content, and strong wear resistance and corrosion resistance. These characteristics determine its immense value as a high-quality building aggregate, but also pose severe challenges to crushing equipment: high wear and high energy consumption.

In the Indonesian market, we must also consider local specificities:

• High humidity and rainy climate: Extremely high requirements for the sealing of electrical and lubrication systems.

• Potentially limited infrastructure: Production line design needs to consider power stability and may require diesel generator backup.

• Sensitive to long-term operating costs: Clients are not only concerned about the initial investment in equipment but also the lifespan of wear parts, energy consumption, and daily maintenance costs.

Therefore, a successful production line solution must be a perfect combination of technology, economics, and local conditions.

II. Core Equipment Selection Strategy for the Production Line

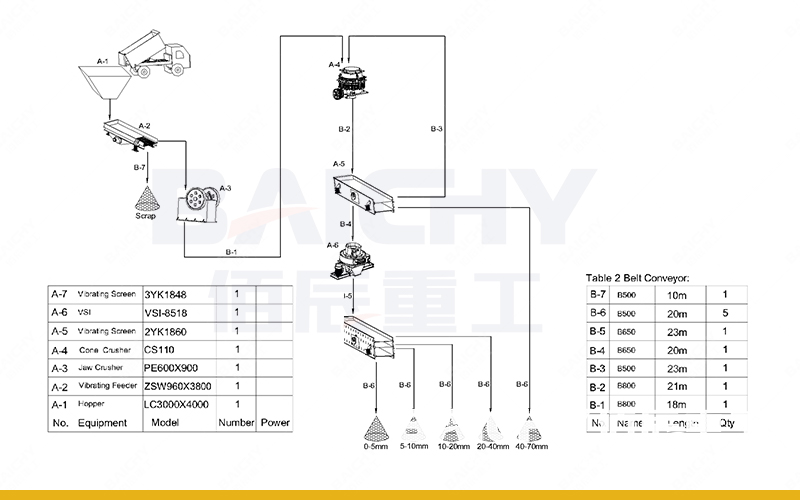

To address the high hardness and high abrasion characteristics of andesite, we abandoned the traditional single jaw crusher solution and adopted a more advanced and efficient two-stage crushing process of jaw crusher + cone crusher. This configuration is the golden combination for achieving high output and excellent particle shape.

1. First-Stage Crushing: Heavy-Duty Jaw Crusher The Stable Pioneer

◦ Equipment Selection: PE Series Deep Cavity Jaw Crusher

◦ Core Advantages: A huge crushing ratio and a robust structure, specifically designed for processing large, hard andesite raw materials. Like a giant steel jaw, it steadily completes the primary coarse crushing task, laying a solid foundation for subsequent crushing. The optimized cavity design not only increases output but also effectively reduces jaw plate wear, lowering long-term operating costs.

2. Secondary Crushing: Multi-functional Hydraulic Cone Crusher A Refined Shaper

◦ Equipment Selection: HPC series multi-cylinder hydraulic cone crusher.

◦ Core Advantages: This is the essence of the entire production line. The hydraulic system enables automatic overload protection and cavity shape adjustment, ensuring automatic pressure relief when encountering uncrushable foreign objects, maximizing the protection of the main unit. Precise control of the closed-side discharge port easily shapes the medium-crushed stone into high-quality aggregates with low needle-like and flaky content, greatly increasing product added value. Its layered crushing principle significantly reduces the wear rate of vulnerable parts (such as the jaw crusher and crusher walls) while achieving fine crushing.

3. Auxiliary Systems: Indispensable Collaborative Force

◦ Feeding System: ZSW series heavy-duty vibrating feeder, providing uniform and continuous feeding to the jaw crusher, avoiding stalling and ensuring smooth operation of the first process.

◦ Screening System: The 3YK series large circular vibrating screen performs efficient screening, ensuring precise particle size distribution of the final product. Unqualified materials are returned to the cone crusher for further crushing, forming a closed-loop cycle that improves efficiency and yield.

◦ Conveying System: The TD series belt conveyor connects all stages, ensuring smooth material flow.

III. Creating Returns Exceeding Customer Expectations

This production line, customized for an Indonesian customer, not only solved the technical challenges of andesite crushing but also brought significant economic benefits:

• High Output and Excellent Particle Shape: Stable peak output of 150 tons/hour, producing finished aggregates with excellent particle shape, reasonable gradation, and strong market competitiveness.

• Low Operating and Maintenance Costs: Core equipment wear parts are made of ultra-high chromium alloy, extending service life by over 30%; intelligent maintenance of the hydraulic cone crusher reduces downtime and labor costs.

• Excellent Stability and Environmental Friendliness: The equipment operates smoothly with a low failure rate; dust removal and noise reduction equipment can be added to meet local environmental requirements.

In the Indonesian and Southeast Asian markets, facing the challenges of hard rocks like andesite, we leverage our professional technical selection capabilities and extensive project experience to provide clients with comprehensive services, from site surveys and solution design to equipment supply and installation guidance. Choosing us is not just choosing equipment, but also choosing a trustworthy partner to jointly develop the market and create wealth.