Jaw Crusher For Sale Now

Why Choose a Jaw Crusher?

In many fields such as mining and construction waste treatment, primary crushing of materials is the first critical step in the production process, and its efficiency and stability directly affect the output and benefits of the entire production line. As one of the oldest and most technologically mature crushing equipment, the jaw crusher has always held a core position due to its robust structure, powerful crushing force, and wide applicability. When a high-performance jaw crusher is available for sale, it represents an excellent opportunity for customers to directly improve productivity. This article will explore various aspects of jaw crushers to help you make an informed investment decision.

| Key Words | Jaw Crusher For Sale Now |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤1200mm |

| Motor Power | 15-280kw |

| Capacity | 5-1100t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Jaw Crusher Overview: A Robust and Durable Crushing Pioneer

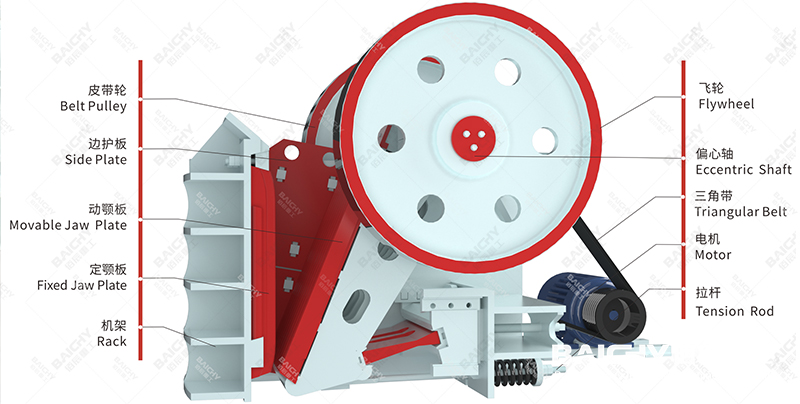

Jaw crusher structural diagram

The working principle of a jaw crusher simulates the movement of an animal's jaws. Its core structure includes a fixed jaw plate and a movable jaw plate. When the movable jaw plate periodically approaches the fixed jaw plate, the material between the two jaw plates is crushed by a combination of compression, splitting, and bending. When the movable jaw plate moves away, the crushed material smaller than the discharge opening is discharged from the bottom of the crushing chamber under gravity.

1. Core Working Principle and Classification

Based on the movement trajectory of the movable jaw plate, jaw crushers can be mainly pided into simple swing type and complex swing type (double swing type). The double swing jaw crusher, due to the different movement trajectories of the top and bottom ends of the jaw plate, simultaneously exerts squeezing and grinding effects, resulting in higher crushing efficiency. It is currently the mainstream model on the market, particularly suitable for processing various ores and rocks of medium to high hardness.

2. Core Advantages of Choosing Our Jaw Crusher

When you consider purchasing a jaw crusher, what value does our equipment offer that surpasses that of our competitors?

3. Superior Crushing Performance and High Reliability

Our jaw crushers use high-quality, high-strength steel and advanced manufacturing processes. The core bearings and jaw plates are specially reinforced, capable of withstanding enormous impact loads and pressures. The equipment operates extremely stably with a low failure rate, ensuring continuous production and high output, providing reliable assurance under heavy-duty conditions.

4. Wide Material Adaptability

Whether it's hard ores such as granite and basalt, or medium-hard materials such as limestone and concrete, our jaw crushers can handle them with ease. By adjusting the size of the discharge port, the particle size of the final product can be easily controlled to meet the crushing needs of different customers.

5. Convenient Maintenance and Economical Operation

The equipment has a reasonable structural design, and key wear parts (such as jaw plates) are easy to replace, effectively reducing downtime. The optimized crushing chamber reduces energy consumption while increasing the crushing ratio, meaning that more qualified material can be produced under the same power, significantly reducing your per-ton production cost.

Somali limestone jaw crusher production line

Success Story: Jaw Crusher in the Field

A large granite quarry previously used an old jaw crusher, which was inefficient and had high maintenance costs. After purchasing our company's PE-750×1060 jaw crusher, the average daily output increased by about 35%, the equipment operated smoothly, and the life of wear parts was extended by 50%. The customer was very satisfied with the return on investment.

Related Equipment Recommendation: Building a Complete Mobile Crushing Production Line

A high-efficiency jaw crusher is the "leader" of a crushing line. To maximize your benefits, we recommend combining it with the following equipment to form a mobile or stationary production line:

• Mobile Jaw Crusher: Integrates feeding, crushing, and conveying, offering flexible relocation options, and is particularly suitable for sand and gravel aggregate production and construction waste recycling projects.

• Cone Crusher: As a medium crushing unit, it processes the semi-finished product from the jaw crusher, producing finished material with a better particle shape.

• Vibrating Screen: Classifies the crushed material, separating it into different sizes of final products.

Frequently Asked Questions (FAQ)

1. What size raw material can a jaw crusher typically handle?

This depends on the specific model. Our jaw crushers range in feed opening size from several hundred millimeters to over one thousand millimeters, typically with a maximum feed size of 80%-85% of the feed opening width, easily handling large pieces of primary ore.

2. What is the typical lifespan of the jaw plates?

The lifespan of the jaw plates is closely related to the hardness, abrasiveness, and output of the material being crushed. Under conditions of crushing medium-hard granite, the lifespan of our high-manganese steel jaw plates is typically 3-6 months, depending on the specific operating conditions.

3. Do you provide installation and commissioning services?

Yes. We provide comprehensive after-sales service to customers worldwide, including guidance on equipment foundation drawings, on-site or remote installation and commissioning guidance from engineers, operator training, etc., to ensure that the equipment can be quickly put into efficient production.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!